Recycling method of scrapped ternary lithium battery

A ternary lithium battery and recovery method technology, applied in battery recovery, waste collector recovery, recycling technology, etc., can solve problems such as low extraction efficiency, affecting recovery rate of hydrometallurgy, difficulty in realizing industrialized operation, etc., to avoid The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

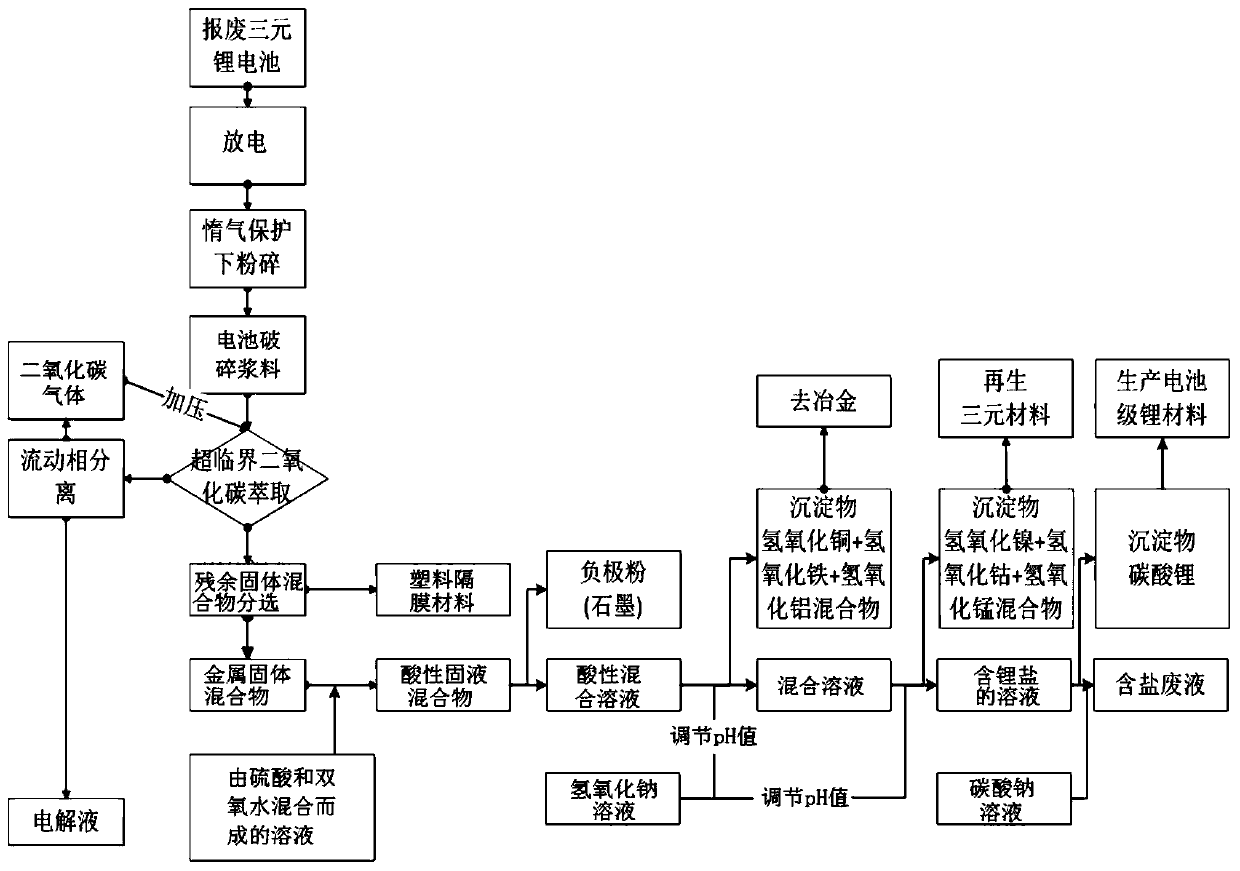

[0030] see figure 1 , shown in the figure is a recycling method for scrapped ternary lithium batteries, including the following steps:

[0031] Step S1, dismantling the scrapped ternary lithium battery into lithium battery cells, and discharging the disassembled lithium battery cells. In this embodiment, the disassembled lithium battery cells are soaked in salt water for discharge treatment, and the discharged lithium battery cells are cleaned to remove the soaking liquid attached to the surface of the lithium battery cells.

[0032] Step S2, in the state of using an inert gas as a protective gas to protect the discharged lithium battery cells, so that the lithium battery cells are crushed to form battery crushed slurry. In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com