Method and system for production of structural component with waste composite material

A composite material and production structure technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, applications, etc., can solve the problems of material waste, limited secondary utilization, low material utilization rate, etc., and achieve a wide range of applications and structural Cleverly designed, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

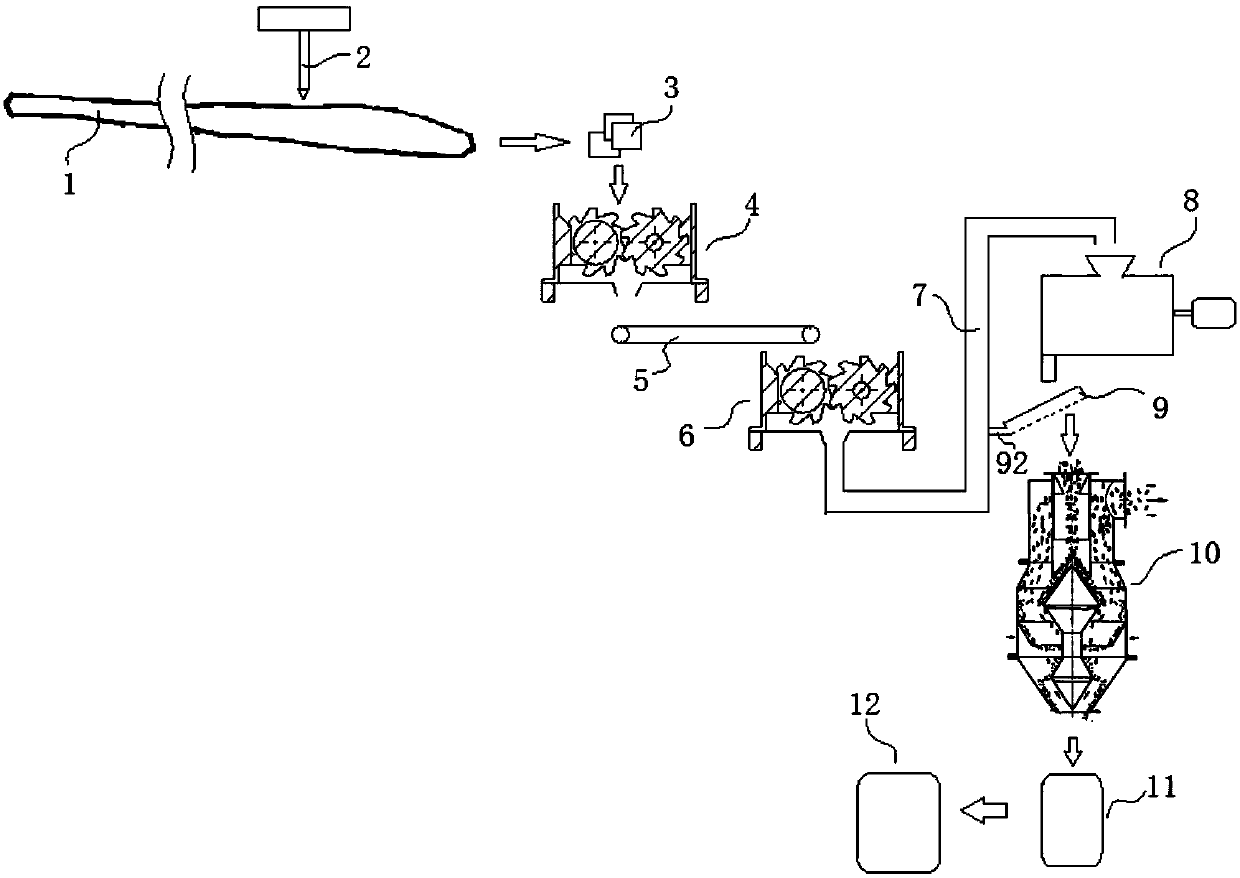

[0064] A method of producing structural parts from waste composite materials, comprising the steps of:

[0065] (1) After crushing waste composite materials and separating resin glass fiber powder and light material powder with a density lower than resin glass fiber powder, the resin glass fiber powder is activated and mixed with resin, short glass fiber, and initiator , release agent and filler are mixed to prepare a doughy mixture;

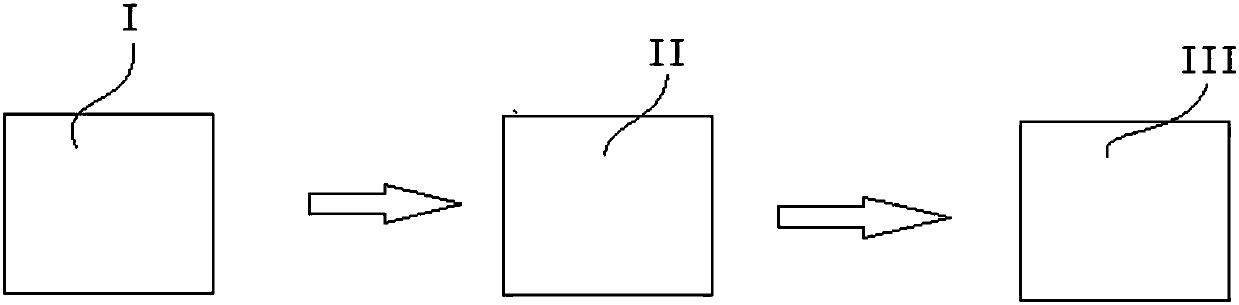

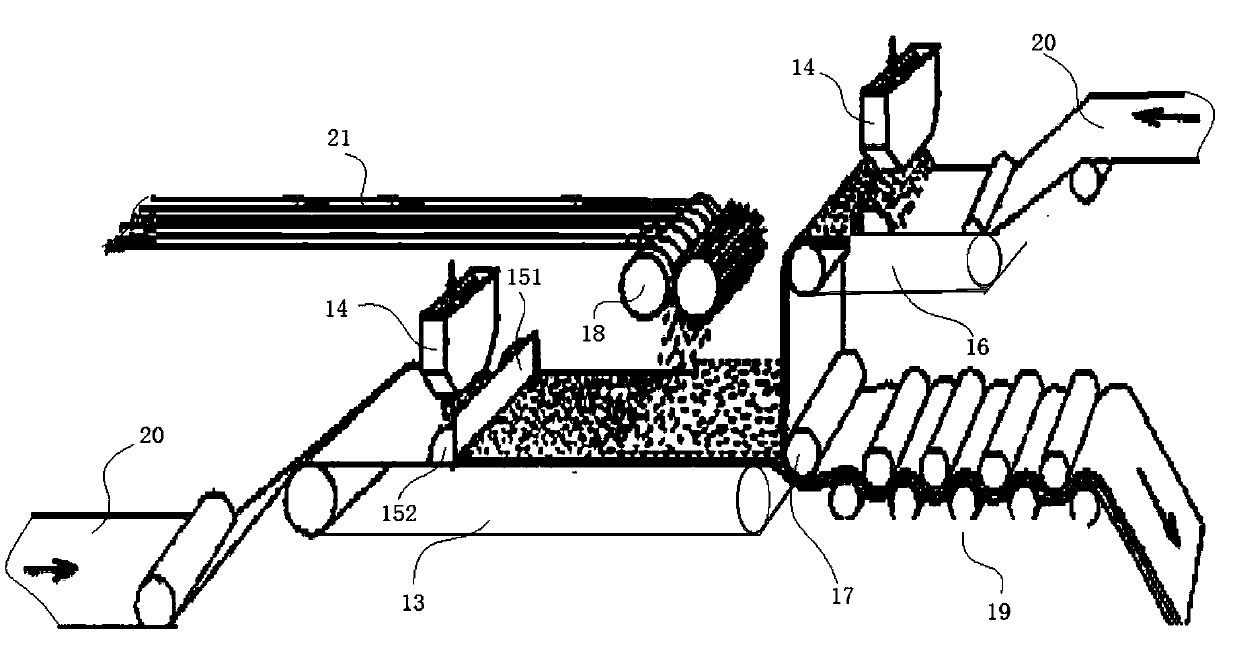

[0066] (2) Deposit the agglomerate mixture on the surface of polyethylene film to form a material film, and roll it with glass fiber cut short filaments to form a sandwich mixture of material film-glass fiber cut short filaments-material film structure, and further roll to form Flake mix;

[0067] (3) The flake compound is prepared into a structural member by compression molding.

[0068] Among them, the discarded composite materials are glass fiber composite materials, including discarded large wind power blades, FRP hulls, radomes or nacelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com