Mesoporous silica nanosphere, preparation method thereof, and application of nanosphere in drug load

A technology of mesoporous silica and nanospheres, applied in silica, silica, nanotechnology and other directions, can solve the problems of low drug dissolution rate and unsatisfactory bioavailability, and achieve theoretical and practical significance. Good application prospect, green and environmental protection effect in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 of the present invention provides a method for preparing mesoporous silica nanospheres, the specific steps are as follows:

[0057] Measure 78mL of deionized water, 27mL of absolute ethanol, and 0.75mL of ammonia water. After mixing, add 0.3g of CTAB (cetyltrimethylammonium bromide) and ultrasonically mix to obtain solution A; measure 1.65mL of TEOS , and fully mixed with 2.175mL of absolute ethanol, wherein the volume ratio of TEOS (tetraethyl orthosilicate) to absolute ethanol is 0.758, to obtain solution B; quickly add solution B to solution A, seal, and magnetically stir React for 24 hours; then filter the obtained product with suction, wash with deionized water and absolute ethanol three times each, until neutral.

[0058] The suction-filtered product was dried at 50° C. for 12 hours, and then calcined in a muffle furnace at 550° C. for 5 hours to obtain mesoporous silica nanospheres with a diameter of 50 nm.

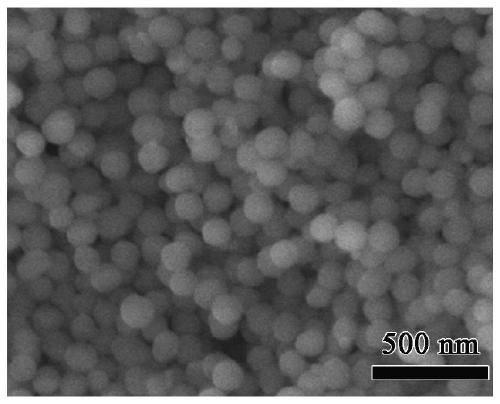

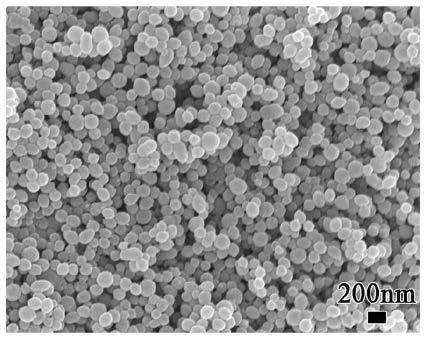

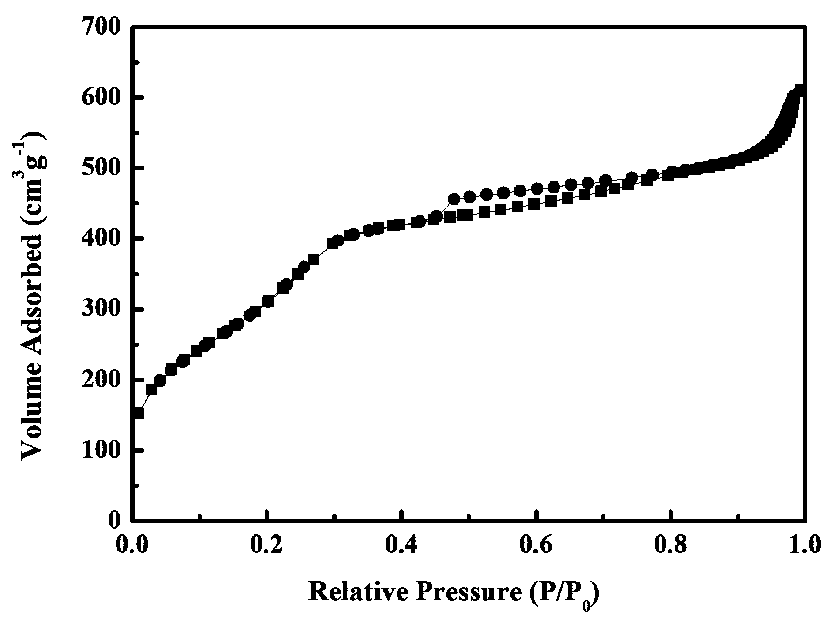

[0059] figure 1 and figure 2 These ar...

Embodiment 2

[0062] Embodiment 2 of the present invention provides a method for preparing mesoporous silica nanospheres, the specific steps are as follows:

[0063] Measure 78mL of deionized water, 27mL of absolute ethanol, and 0.75mL of ammonia water, mix well, add 0.3g of CTAB, and ultrasonically mix to obtain solution A. Measure 1.65mL of TEOS and fully mix with 1.25mL of absolute ethanol, wherein the volume ratio of TEOS to absolute ethanol is 1.32 to obtain solution B. Solution B was quickly added to solution A, sealed, and magnetically stirred for 24 hours. Then the obtained product was subjected to suction filtration, washed with deionized water and absolute ethanol three times, until neutral.

[0064] The suction-filtered product was dried at 50° C. for 12 hours, and then calcined in a muffle furnace at 550° C. for 5 hours to obtain mesoporous silica nanospheres with a diameter of 150 nm.

[0065] Figure 5 and Figure 6 These are the scanning electron micrographs of the mesopo...

Embodiment 3

[0067] Embodiment 3 of the present invention provides a method for preparing mesoporous silica nanospheres, the specific steps are as follows:

[0068] Measure 27mL of deionized water, 78mL of absolute ethanol, and 0.75mL of ammonia water, mix well, add 0.3g of CTAB, and ultrasonically mix to obtain solution A. Measure 1.65mL of TEOS and fully mix with 1.25mL of absolute ethanol, wherein the volume ratio of TEOS to absolute ethanol is 1.32 to obtain solution B. Solution B was quickly added to solution A, sealed, and magnetically stirred for 24 hours. Then the obtained product was subjected to suction filtration, washed with deionized water and absolute ethanol three times, until neutral.

[0069] The suction-filtered product was dried at 50° C. for 12 hours, and then calcined in a muffle furnace at 550° C. for 5 hours to obtain mesoporous silica nanospheres with a diameter of 1 μm.

[0070] Figure 7 and Figure 8 These are the scanning electron micrographs of the mesoporo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com