A method for synthesizing 1,4-naphthoquinone cyclopropane compounds

A compound, cyclopropane technology, applied in the field of organic compound synthesis, can solve the problems of large quantities and unfavorable industrial production, and achieve the effects of mild reaction conditions, good substrate adaptability and low operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

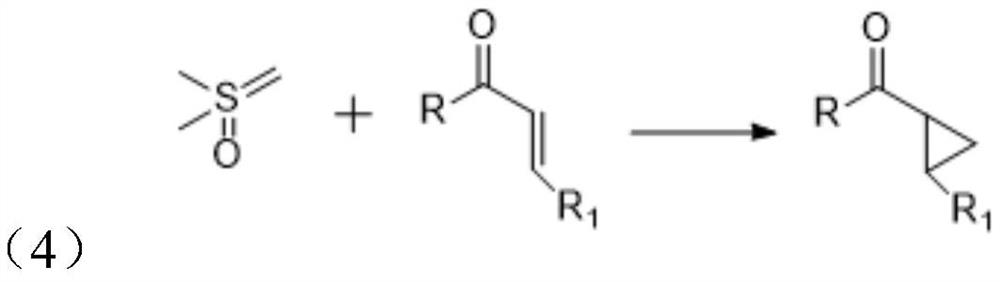

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

[0037] Add 0.3mmol (E)-3-phenyl-1-(2-(phenylethynyl)phenyl)prop-2-en-1-one, 0.06mmol ferric chloride, 0.9mmol diiodine pentoxide to In a 15mL thick-walled pressure-resistant reaction tube, add 3mL of 1,4-dioxane as a solvent. Next, magnetic stirring was performed at 100° C. for 0.5 hours. After being cooled to room temperature, two spoonfuls of column chromatography silica gel (100-200 mesh) were added in the reaction solution, and the solvent was removed by distillation under reduced pressure, and then the pure product as shown in the structural formula was obtained by column chromatography separation (in petroleum ether / ethyl acetate=20:1 as eluent). The material was a white solid, 68% yield.

[0038] Characterization data: 1 H NMR (500MHz, CDCl 3 ): δ8.21-8.18(m, 1H), 8.15, -8.12(m, 1H), 7.84-7.80(m, 2H), 7.27-7.24(m, 3H), 7.17-7.09(m, 5H), 6.78(d, J=7Hz, 2H), 3.69(d, J=6Hz, 1H), 3.45(d, J=6Hz, 1H)

[0039] 13 C NMR (125MHz, CDCl 3 ):δ192.73,191.06,134....

Embodiment 2

[0041]

[0042]0.3mmol (E)-1-(2-(phenylethynyl)phenyl)-3-(o-tolyl)prop-2-en-1-one, 0.06mmol iron nitrate, 0.9mmol diiodine pentoxide Add it into a 15mL thick-walled pressure-resistant reaction tube, and then add 3mL of 1,4-dioxane as a solvent. Next, magnetic stirring was performed at 100° C. for 0.5 hours. After being cooled to room temperature, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the pure product (in petroleum ether) was obtained by column chromatography separation as shown in the structural formula / ethyl acetate=20:1 as eluent). The material was a white solid, 51% yield.

[0043] Characterization data: 1 H NMR (500MHz, CDCl 3 ): δ8.25-8.20(m, 1H), 8.17-8.12(m, 1H), 7.84-7.79(m, 2H), 7.22-7.17(m, 3H), 7.15-7.11(m, 3H), 7.06- 7.03(m, 1H), 6.86(t, J=8Hz, 1H), 6.54(d, J=8Hz, 1H), 3.87(d, J=8Hz, 1H), 3.50(d, J=8Hz, 1Hz) ,2.40(s,3H). ...

Embodiment 3

[0046]

[0047] 0.3mmol (E)-3-(2-methoxyphenyl)-1-(2-(phenylethynyl)phenyl)prop-2-en-1-one, 0.03mmol ferric chloride, 0.9 Add mmol diiodine pentoxide to a 15 mL thick-walled pressure-resistant reaction tube, and then add 3 mL of 1,4-dioxane as a solvent. Next, magnetic stirring was performed at 100° C. for 0.5 hours. After being cooled to room temperature, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the pure product (in petroleum ether) was obtained by column chromatography separation as shown in the structural formula / ethyl acetate=20:1 as eluent). The material was a white solid in 78% yield.

[0048] Characterization data: 1 H NMR (500MHz, CDCl 3 ): δ8.23-8.19(m, 1H), 8.14-8.10(m, 1H), 7.81-7.77(m, 2H), 7.22-7.17(m, 5H), 7.13-7.10(m, 1H), 6.80 (d, J=8Hz, 1H), 6.61(t, J=8Hz, 1H), 6.52(dd, J 1 =7.5Hz,J 2 =1Hz, 1H)3.82(s, 3H), 3.77-3.74(m,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com