Preparation method of water-swelling rubber

A technology of water-swellable rubber and preparation steps, which is applied in the field of rubber materials, can solve problems such as poor salt resistance, and achieve the effects of improved salt resistance, good salt resistance, and perfect rubber interpenetrating network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

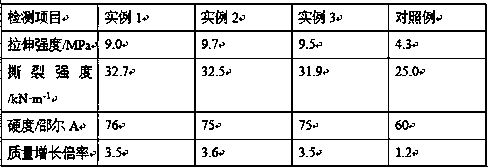

Examples

example 1

[0030] Take gelatinized starch, maleic anhydride monomer, acrylamide, acrylic acid, 1,2-polybutadiene, benzoyl peroxide, formaldehyde, dimethylamine, maleic anhydride monomer, acrylamide, acrylic acid, 1 , 2-polybutadiene and benzoyl peroxide are melted and mixed to obtain a melt, and gelatinized starch is added to the melt and stirred at a constant temperature to obtain a mixture. Formaldehyde and dimethylamine are added to the mixture, and Stir at 45°C for 1 hour, filter the precipitate, wash the precipitate twice with deionized water, dry it in an oven at 50°C to constant weight, and cool to room temperature to obtain a water-absorbing filler; take nitrile rubber, Water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010, salt hornwort extract, nitrile rubber, water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010 and salt horn grass The extracts are mixed and kneaded evenly to obtain a precursor, which is placed on a f...

example 2

[0032] Take gelatinized starch, maleic anhydride monomer, acrylamide, acrylic acid, 1,2-polybutadiene, benzoyl peroxide, formaldehyde, dimethylamine, maleic anhydride monomer, acrylamide, acrylic acid, 1 , 2-polybutadiene and benzoyl peroxide are melted and mixed to obtain a melt, and gelatinized starch is added to the melt and stirred at a constant temperature to obtain a mixture. Formaldehyde and dimethylamine are added to the mixture, and Stir for 1.5 hours at a temperature of 50°C, filter to obtain a precipitate, wash the precipitate twice with deionized water, and dry it in an oven at a temperature of 55°C to constant weight, and cool to room temperature to obtain a water-absorbing filler; take nitrile rubber , water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010, salt hornwort extract, nitrile rubber, water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010 and salt horn The grass extract is mixed and kneaded even...

example 3

[0034] Take gelatinized starch, maleic anhydride monomer, acrylamide, acrylic acid, 1,2-polybutadiene, benzoyl peroxide, formaldehyde, dimethylamine, maleic anhydride monomer, acrylamide, acrylic acid, 1 , 2-polybutadiene and benzoyl peroxide are melted and mixed to obtain a melt, and gelatinized starch is added to the melt and stirred at a constant temperature to obtain a mixture. Formaldehyde and dimethylamine are added to the mixture, and Stir for 2 hours at a temperature of 55°C, filter to obtain a precipitate, wash the precipitate with deionized water three times, and dry it in an oven at a temperature of 60°C to constant weight, and cool to room temperature to obtain a water-absorbing filler; take nitrile rubber, Water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010, salt hornwort extract, nitrile rubber, water-absorbing filler, dicumyl peroxide, white carbon black, anti-aging agent 4010 and salt horn grass The extracts are mixed and kneaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com