Barium-free soft film antirust oil

A technology of barium-free antirust agent and antirust oil, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of environmental pollution, poor antirust performance, short antirust period, etc. Excellent, anti-moisture and heat resistance, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

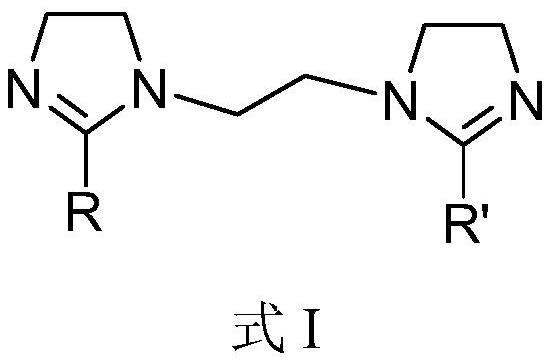

Method used

Image

Examples

Embodiment 1

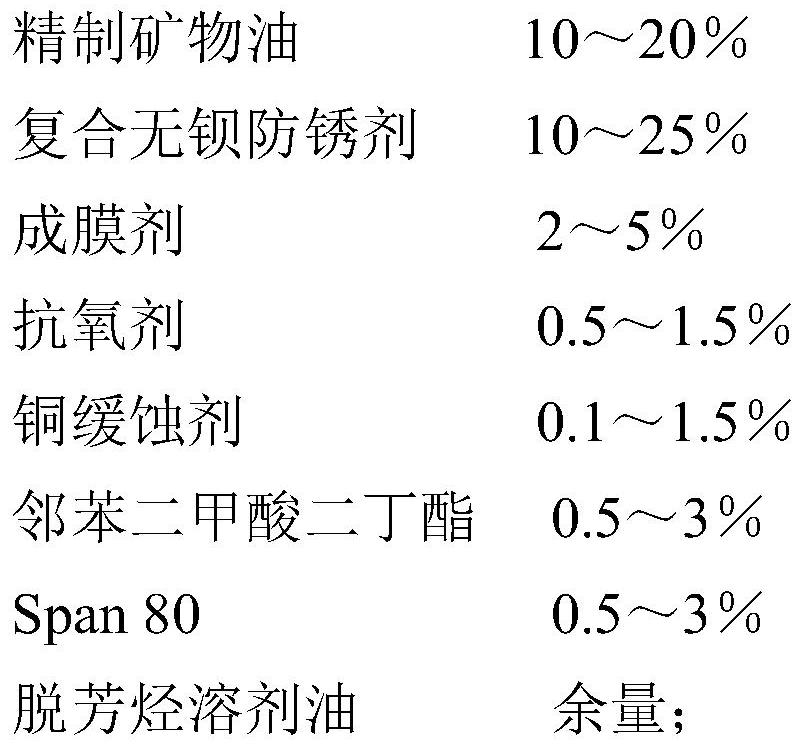

[0045] A barium-free soft film anti-rust oil, based on its total weight as 100%, its components and contents are shown in Table 1.

[0046] Table 1. The composition of embodiment 1 barium-free soft film antirust oil

[0047]

Embodiment 2

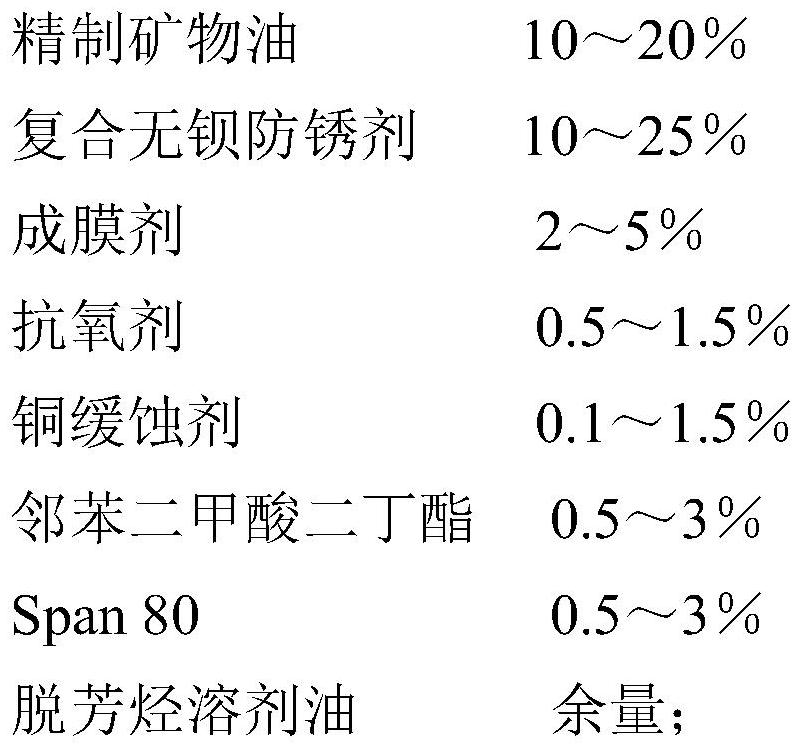

[0049] A barium-free soft film antirust oil, its components and contents are shown in Table 2 based on its total weight as 100%.

[0050] Table 2. The composition of embodiment 2 barium-free soft film antirust oil

[0051]

Embodiment 3

[0053] A barium-free soft film anti-rust oil, based on its total weight as 100%, its components and contents are shown in Table 3.

[0054] Table 3. The composition of embodiment 3 barium-free soft film antirust oil

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com