Health care composite material and preparation method thereof

A technology of composite materials and metal materials, which is applied in the field of health care composite materials and its preparation, can solve the problems of limited application, chronic poisoning of human body, etc., and achieve the effect of improved content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

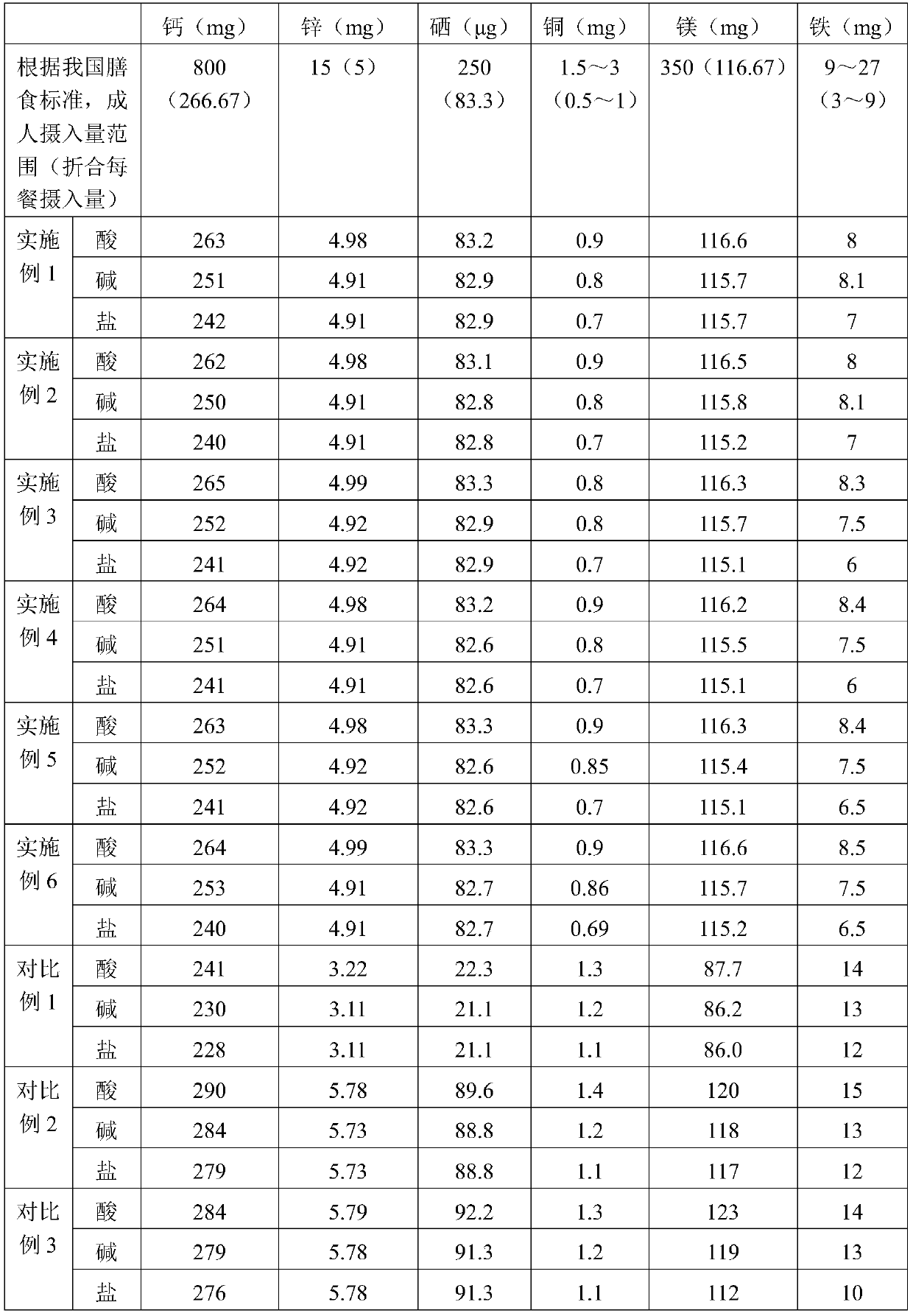

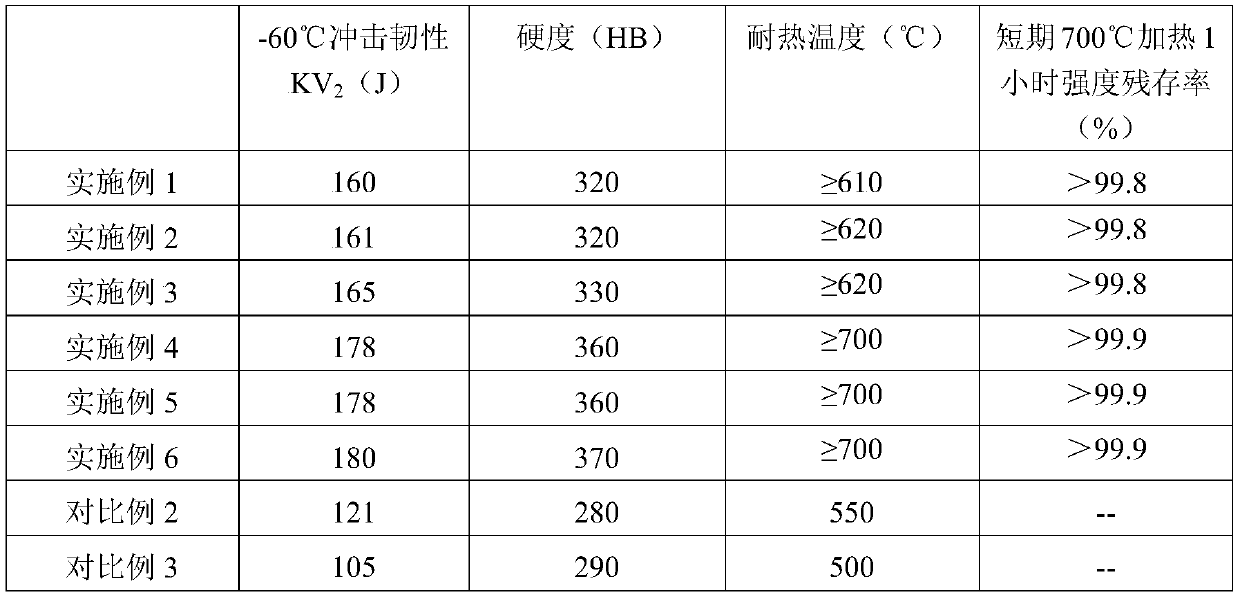

Examples

Embodiment 1

[0065] A health care composite material, comprising the following components by weight percentage: 1% high-purity calcium, 30% high-purity zinc, 0.2% high-purity selenium, 5% high-purity iron, 1% high-purity copper, and the balance is high-purity magnesium. The purity is above 99.99%.

[0066] The preparation method of the above-mentioned health care composite material comprises the following steps:

[0067] (1) Preheat high-purity calcium, high-purity magnesium, high-purity zinc, high-purity iron, and high-purity copper to 350°C, high-purity iron and high-purity copper to 950°C, and high-purity selenium by baking in a baking oven. Heat to 110°C to get the preheated raw materials, set aside;

[0068] (2) Preheat the first vacuum muffle furnace to 300°C, then put the high-purity magnesium preheated in step (1) into the furnace to melt, add high-purity selenium when the high-purity magnesium melts into liquid, and stir for 15 minutes; Then heat up to 710°C, add high-purity zin...

Embodiment 2

[0078] A health care composite material, comprising the following components by weight percentage: 35% high-purity calcium, 1% high-purity zinc, 1% high-purity selenium, 3.5% high-purity iron, 2% high-purity copper, and the balance is high-purity magnesium. The purity is above 99.99%.

[0079] The preparation method of the above-mentioned health care composite material comprises the following steps:

[0080] (1) Preheat high-purity calcium, high-purity magnesium, high-purity zinc, high-purity iron, and high-purity copper to 250°C, high-purity iron and high-purity copper to 1000°C, and high-purity selenium by baking in a baking oven. Heat to 90°C to get the preheated raw materials and set aside;

[0081] (2) Preheat the first vacuum muffle furnace to 400°C, then put the high-purity magnesium preheated in step (1) into the furnace to melt, add high-purity selenium when the high-purity magnesium melts into liquid, and stir for 5 minutes; Then heat up to 720°C, add high-purity z...

Embodiment 3

[0091] A health care composite material, comprising the following components by weight percentage: 35% high-purity calcium, 20% high-purity zinc, 0.5% high-purity selenium, 4% high-purity iron, 1.5% high-purity copper, and the balance is high-purity magnesium. The purity is above 99.99%.

[0092] The preparation method of the above-mentioned health care composite material comprises the following steps:

[0093] (1) Preheat high-purity calcium, high-purity magnesium, high-purity zinc, high-purity iron, and high-purity copper to 300°C, high-purity iron and high-purity copper to 980°C, and high-purity selenium by baking in a baking oven. Heat to 100°C to get the preheated raw materials and set aside;

[0094] (2) Preheat the first vacuum muffle furnace to 350°C, then put the high-purity magnesium preheated in step (1) into the furnace to melt, add high-purity selenium when the high-purity magnesium melts into liquid, and stir for 10 minutes; Then heat up to 715°C, add high-puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com