Configurable PLC based on PCIe bus

A bus and configuration technology, applied in the program control of sequence/logic controller, electrical program control, etc., can solve the problems of unguaranteed performance, loss of communication system data packets, and decrease of transmission rate, etc., and achieve interconnection structure Flexible and configurable, timely and secure data transmission, and high transmission reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A configurable PLC based on the PCIe bus proposed by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

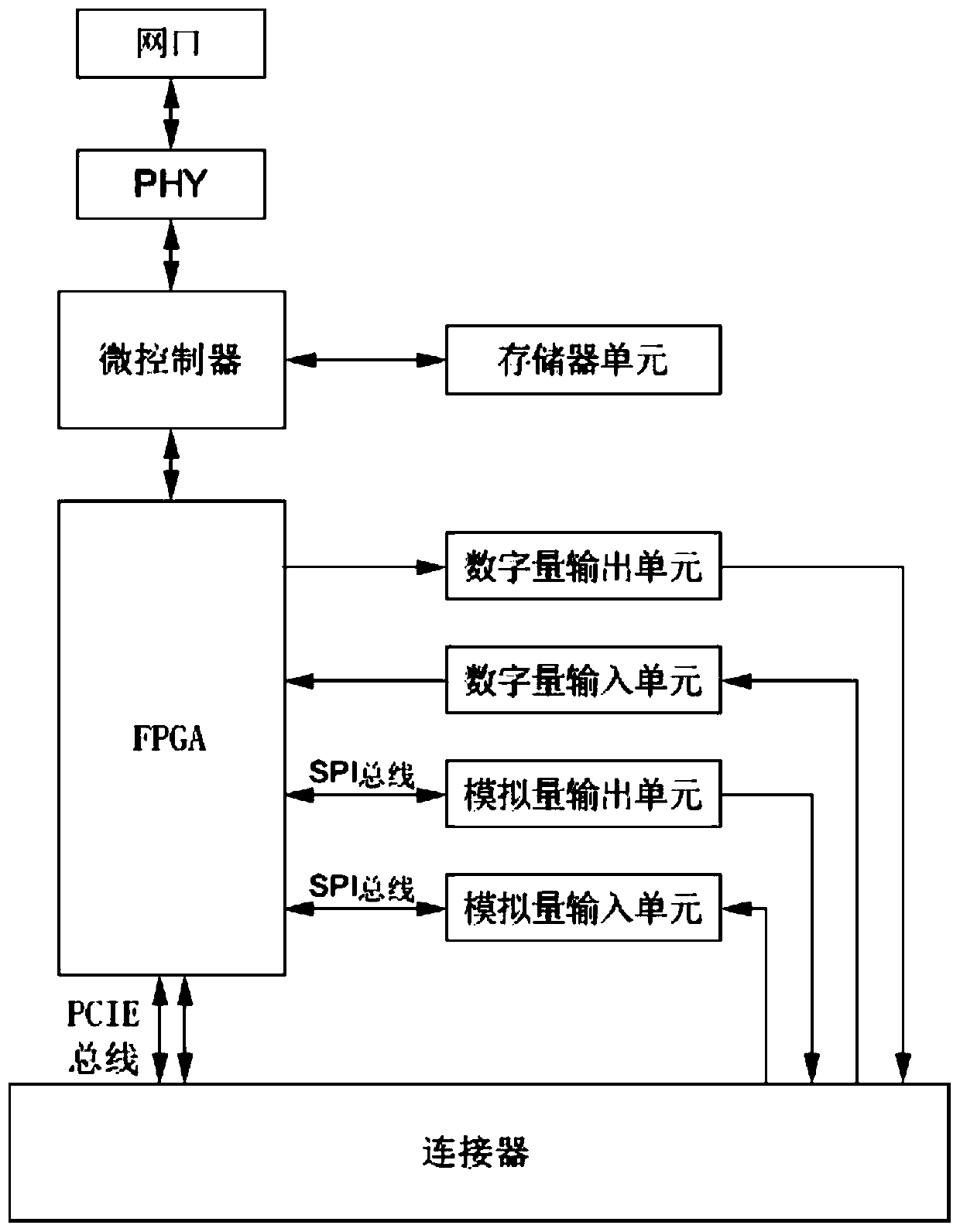

[0030] see figure 1 , the present embodiment provides a configurable PLC based on PCIe (Peripheral Component InterconnectExpress, peripheral device interconnect bus bus), including:

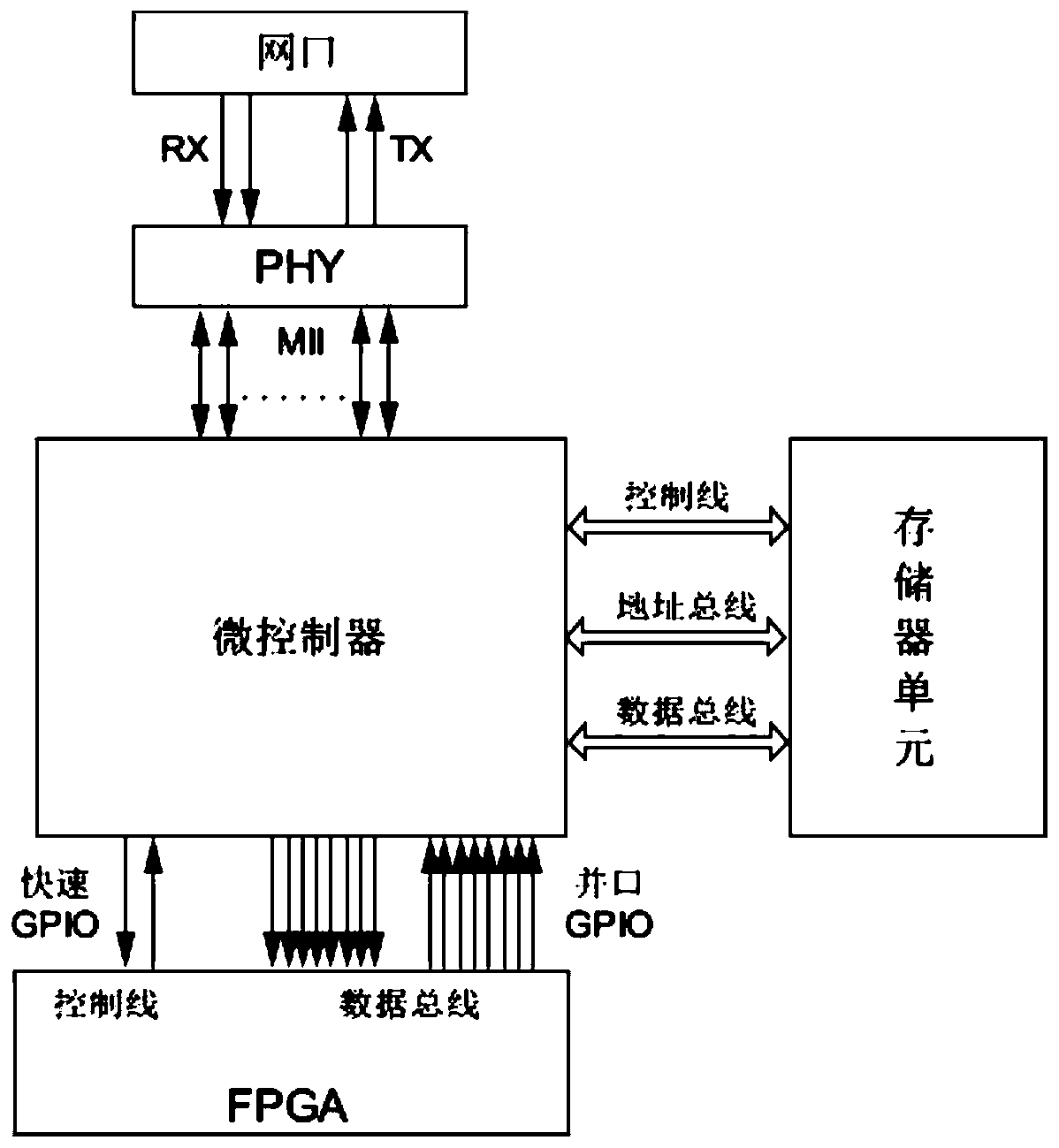

[0031] Microcontroller, FPGA (Field Programmable Gate Array, Field Programmable Gate Array), PHY chip, memory unit, digital input unit, digital output unit, analog input unit and analog output unit;

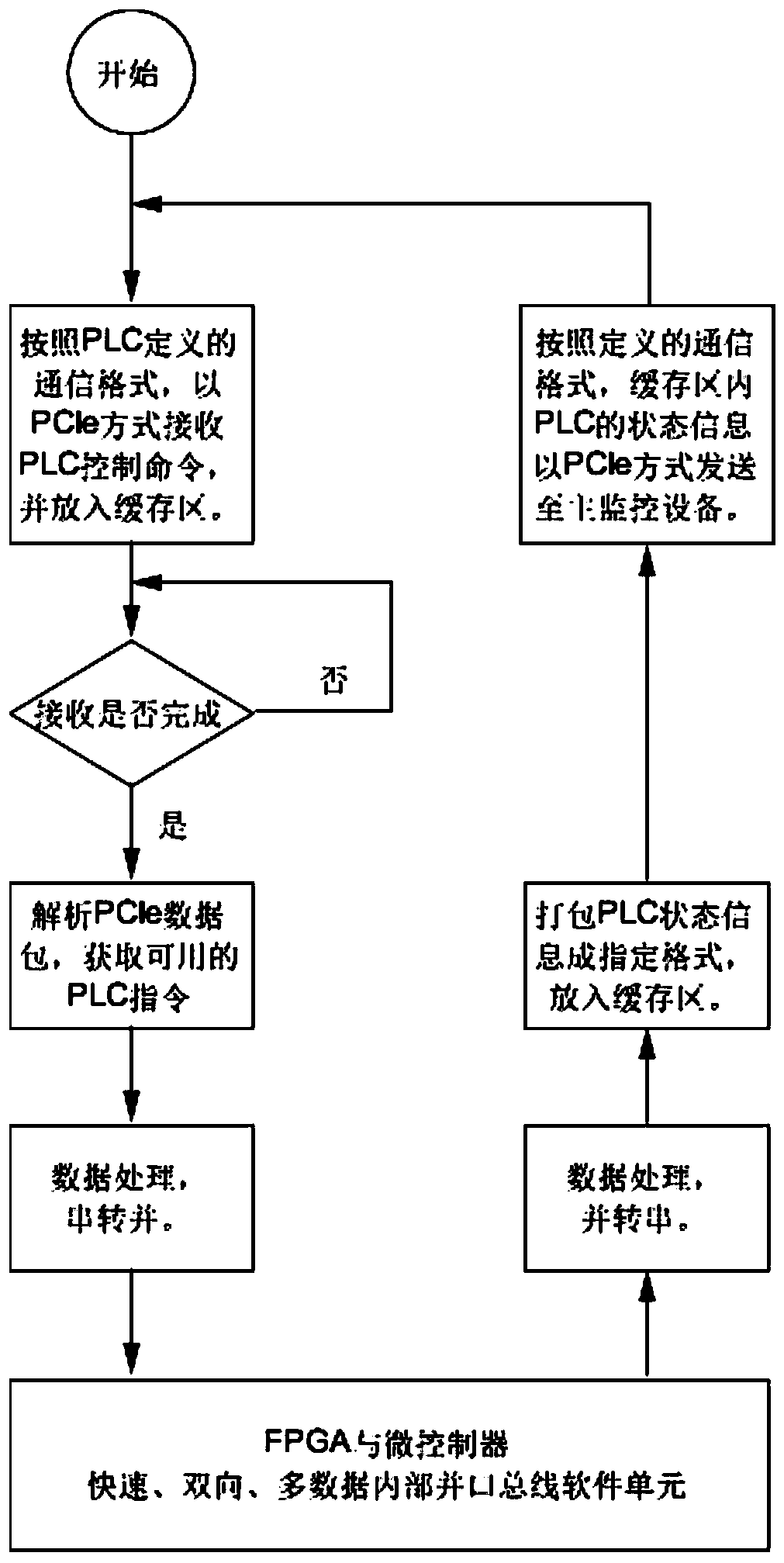

[0032] FPGA is equipped with PCIe interface, GPIO parallel port, SPI interface, and IO interface. Among them, PCIe interface is used for data communication between FPGA and PCIe bus, GPIO parallel port is used for data communication between FPGA and microcontroller, and IO interface is used for FPGA to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com