Automated 5G (the 5th generation wireless systems) base station ceramic filter production line

A ceramic filter and production line technology, applied in the field of 5G communication, can solve problems such as affecting the speed of product replacement, adverse effects on the overall performance of base stations, and large differences in the thickness of the silver paste layer, achieving high accuracy, guaranteed quality, and uniform thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

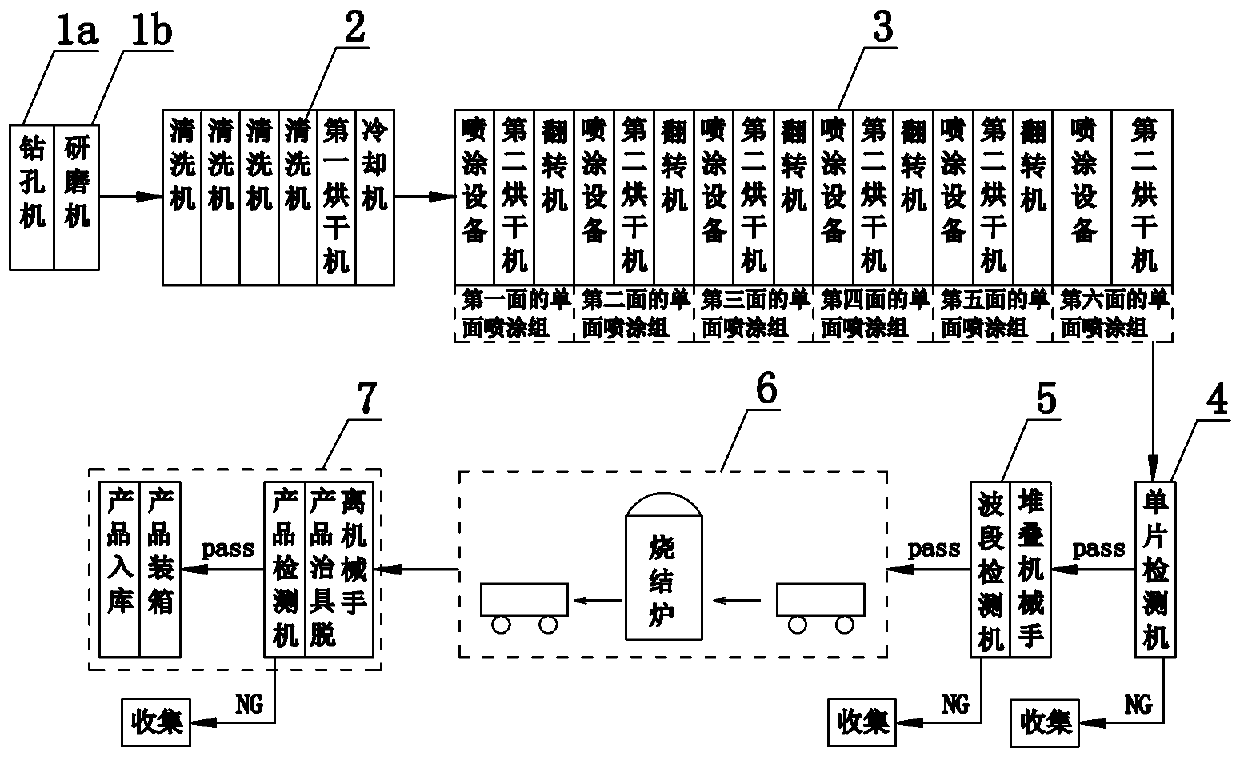

[0018] refer to figure 1 , an automated 5G base station ceramic filter production line, which sequentially includes a drilling station 1a, a grinding station 1b, an ultrasonic cleaning station 2, a silver paste spraying station 3, a single-chip inspection station 4, a stacking station 5, and a sintering station. Forming station 6 and unloading packaging 7, and between two adjacent stations are equipped with manipulators for transferring products.

[0019] refer to figure 1 , specifically, the drilling station 1a is a drilling machine, and the surface of the monolithic ceramics is drilled with the drilling machine; the grinding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com