Kitchen waste sorting and pulping method and large-substance sorting machine and fine pulper thereof

A technology for kitchen waste and sorting machine, which is applied in the direction of grain processing and solid waste removal, etc., can solve the problems of large oil loss, high equipment failure rate and wear, and large oil loss, so as to reduce the loss of oil and organic matter. , The effect of improving work reliability and low oil loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

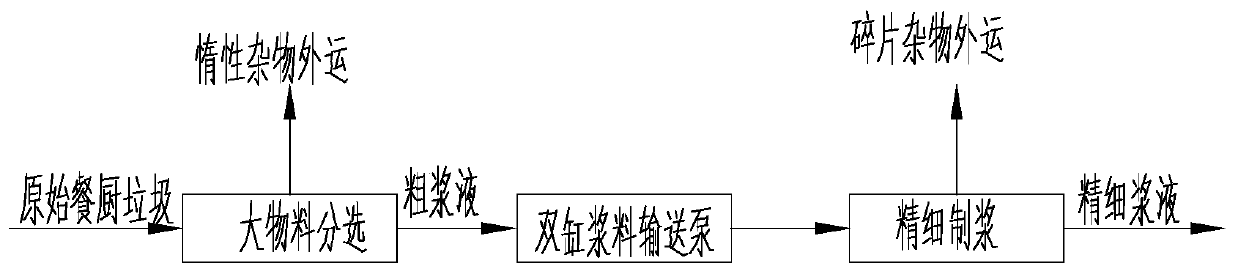

[0035] See figure 1 Shown, the food waste sorting pulping method of the present invention, carry out according to the following steps:

[0036] ⑴ Sorting of large materials.

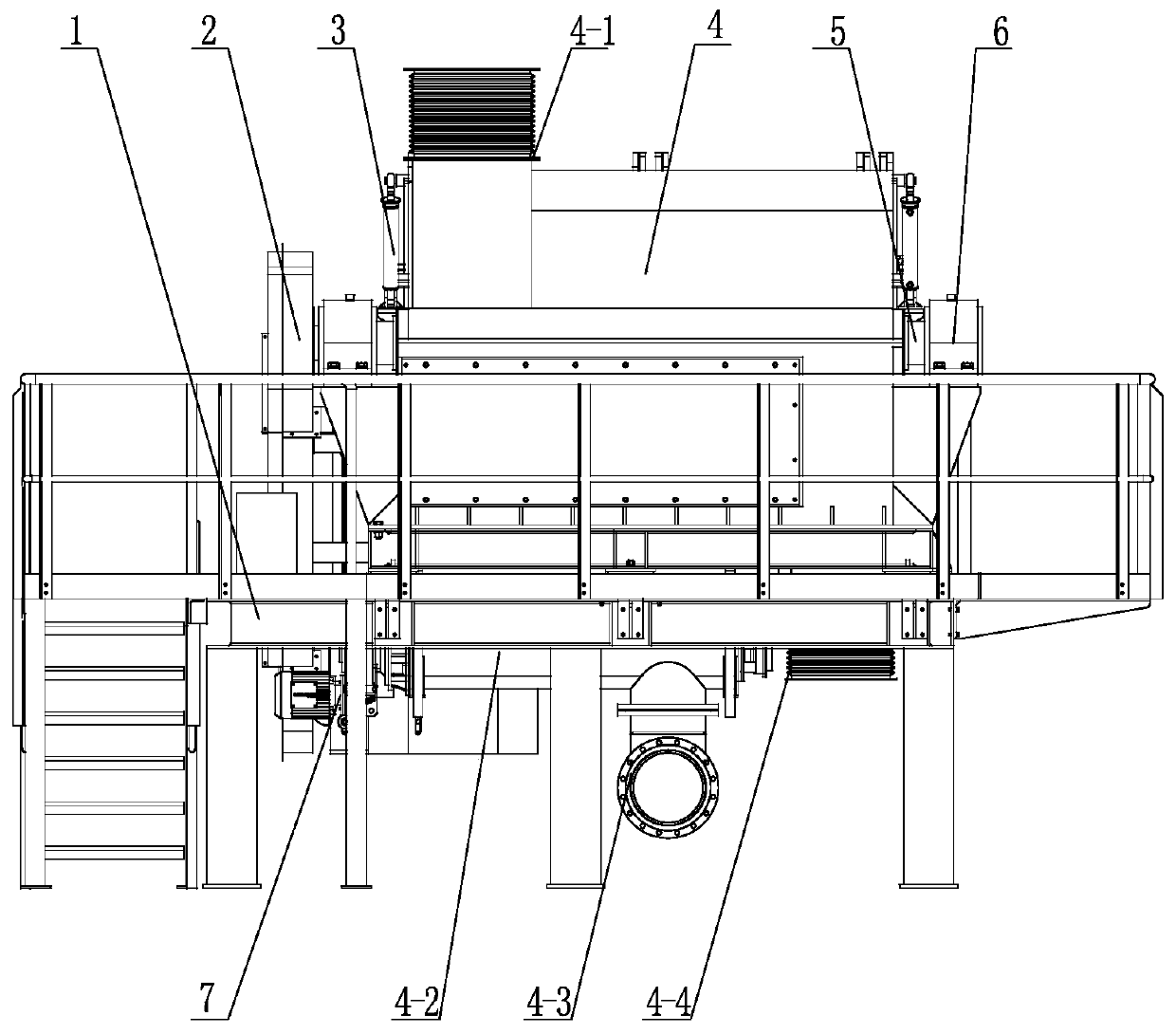

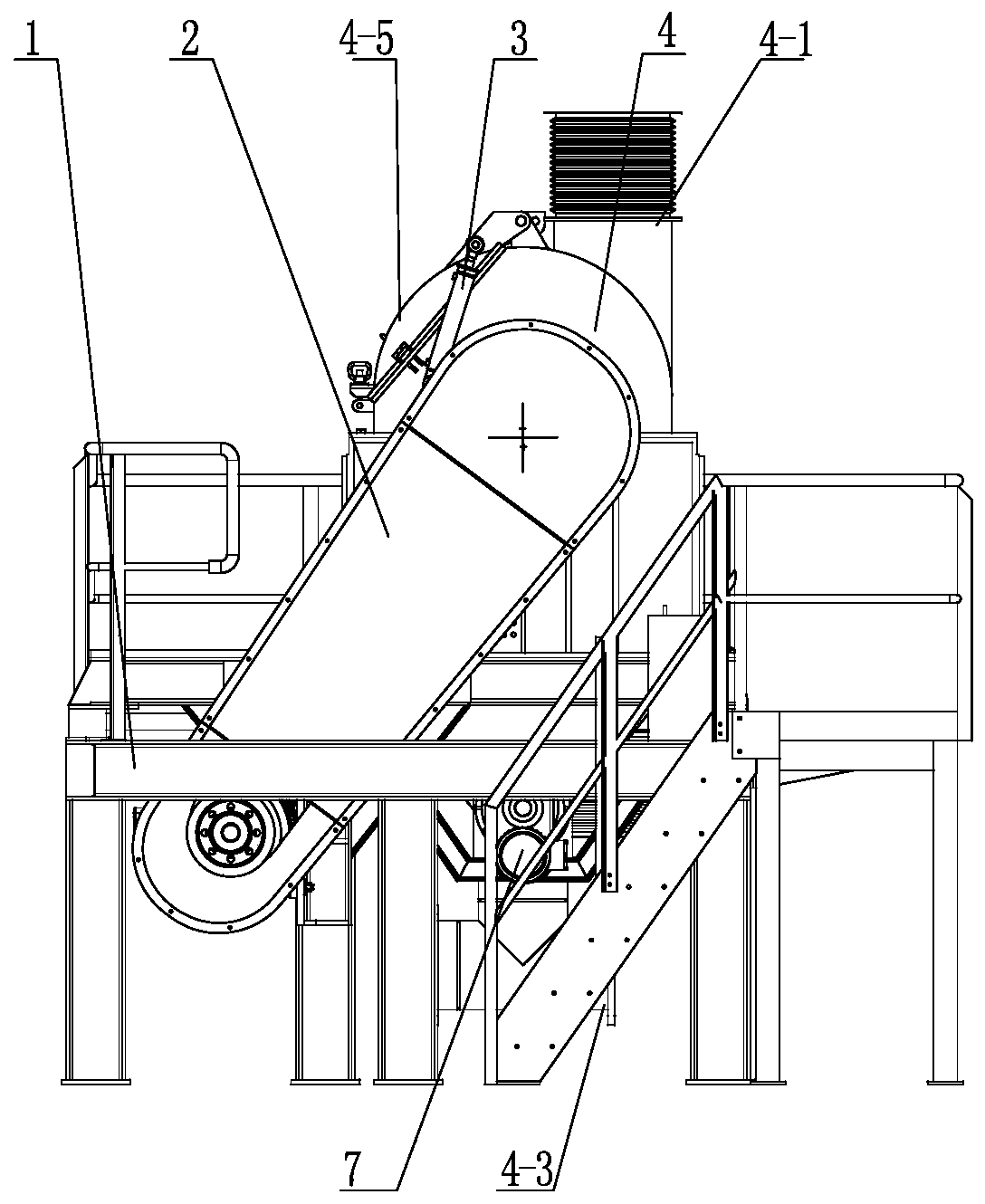

[0037] The original food waste is transported to the working compartment of the large material sorting machine, and the screw conveyor can be used to transport the original food waste to the large material sorting machine. Rotate to disperse the inert bulky debris in the food waste without breaking them, and at the same time, multiple groups of stripping conveying knives 8 rub against the dispersed inert debris to clean the oil-water mixture and some organic matter attached to the inert debris. Peel off and move towards the outlet direction, the sorted feed liquid is filtered through the coarse steel screen plate 10 and flows into the coarse slurry temporary storage bin 4-2 at the lower part, the crude steel screen plate 10 can be semicircular, and the coarse steel screen plate The sieve hole diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com