Method and equipment for simultaneously rolling and polishing inner surface and outer surface of large thin-wall cylindrical workpiece

A processing method and technology of inner and outer surfaces, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as inconsistent quality, workpiece deformation, and low efficiency, and achieve simple equipment structure and processing efficiency High and uniform processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

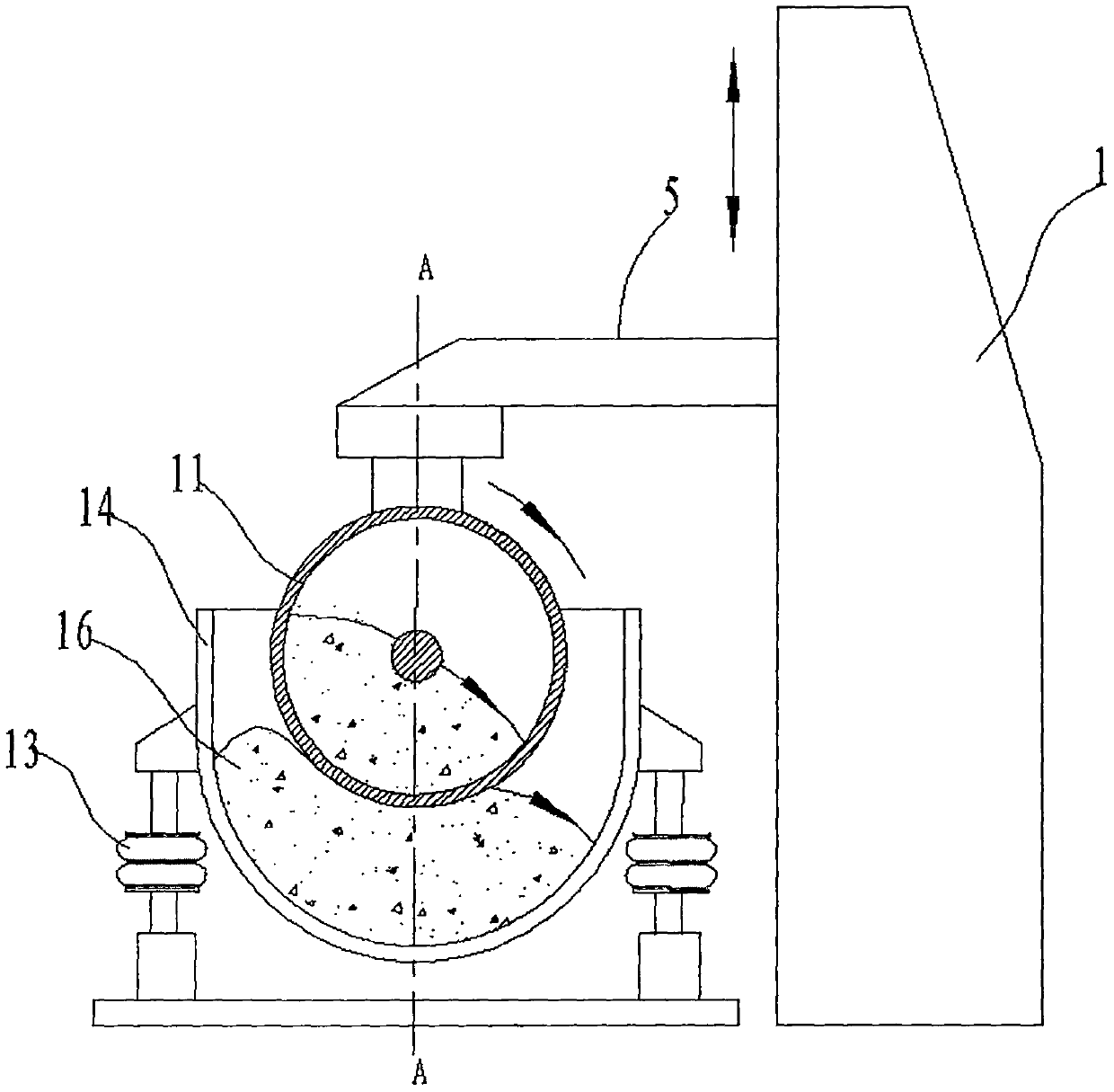

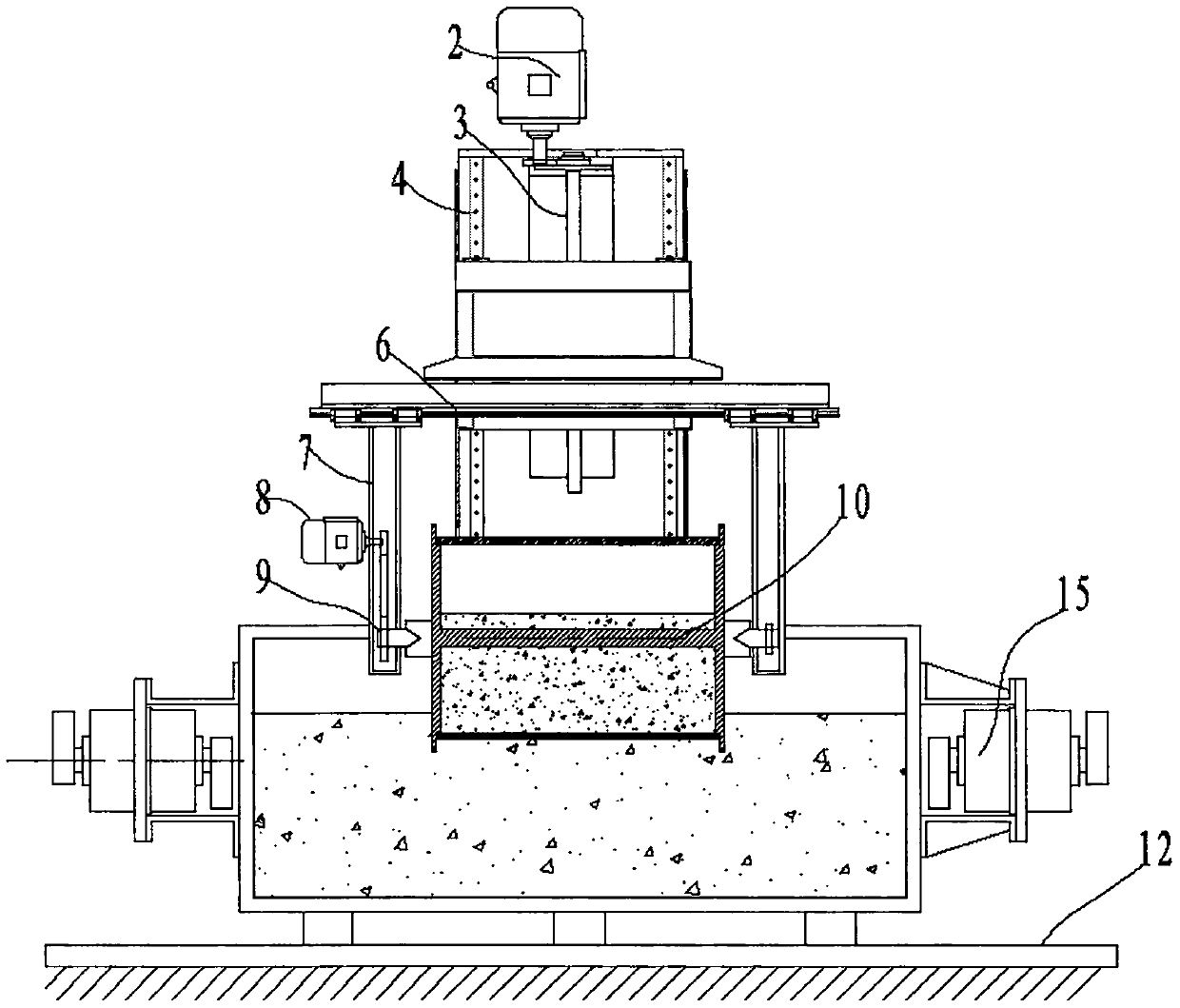

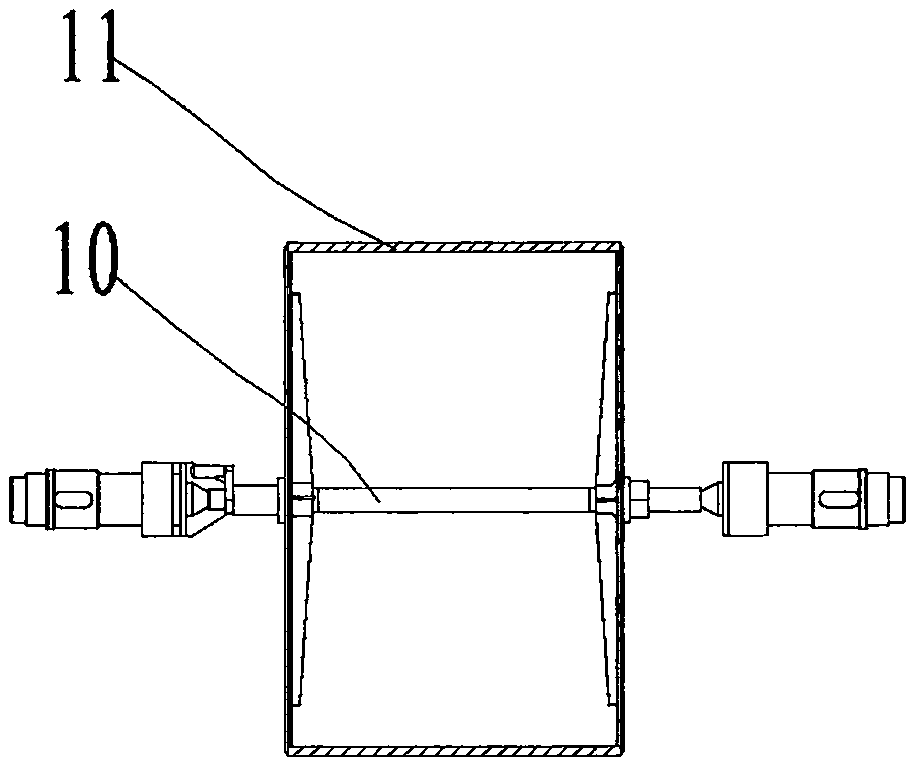

[0031] The motor 2 used for workpiece lifting is installed on the frame 1 of the whole machine, and cooperates with the linear motion unit 3 also installed on the frame 1 of the whole machine; the lifting mounting frame 5 of the workpiece is installed on the linear motion unit 3, and is The workpiece is lifted (or lowered) according to the action of the linear motion unit 3; the lifting auxiliary guide rail 4 is installed on the frame 1 of the whole machine for guiding and assisting positioning of the workpiece lifting (or lowering); the lifting frame 5 is installed with a moving The slide rail 6 and the spindle box 7 are installed on the moving slide rail 6, and through the meshing behavior with the gear 9 also installed on the spindle box 7, the torque is transmitted, and the workpiece clamping tool 10 coaxial with the gear 9 and the tooling are driven. The workpiece 11 is rotated in forward and reverse directions; a shock absorber 13 is installed on the equipment base 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com