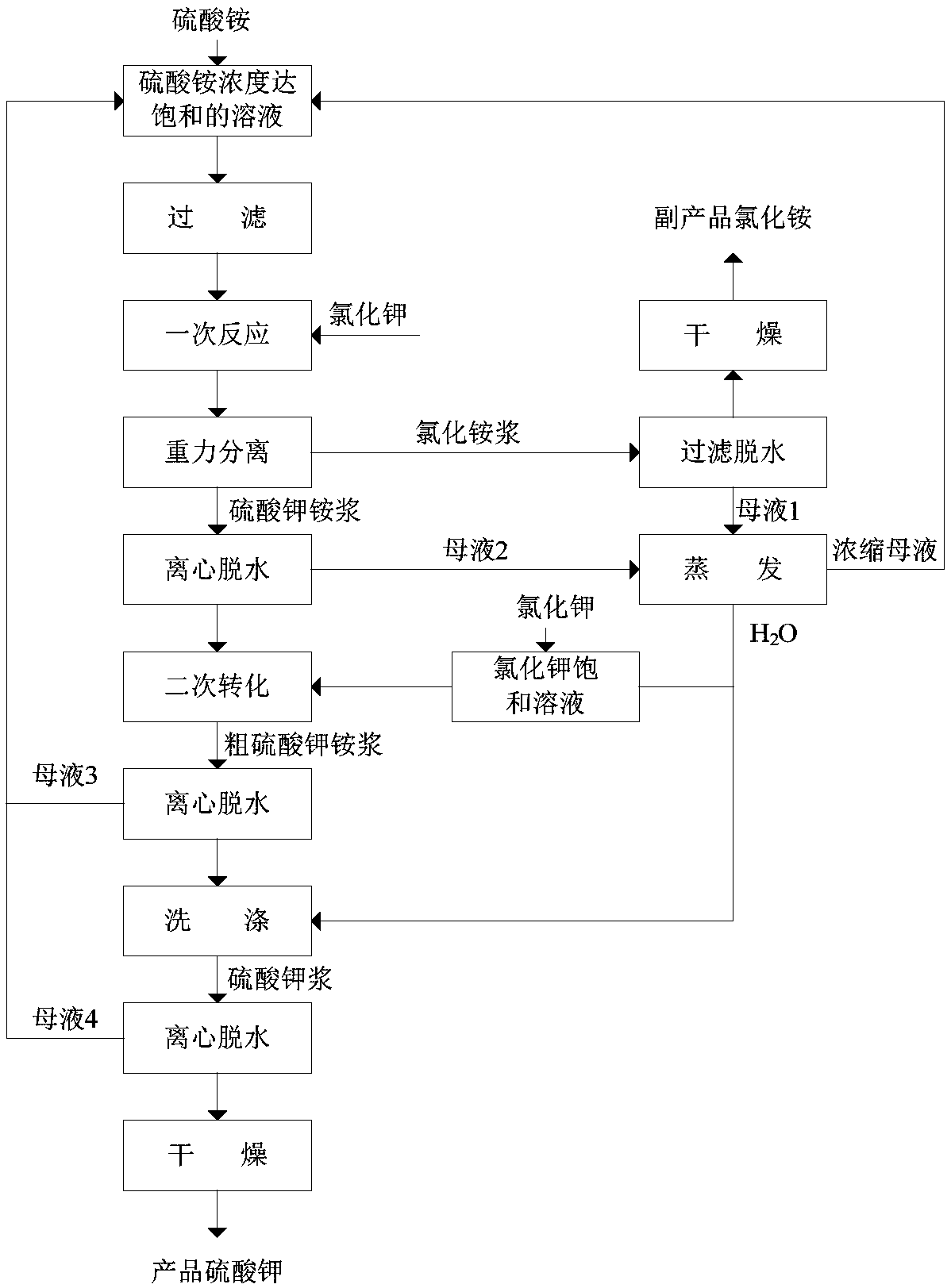

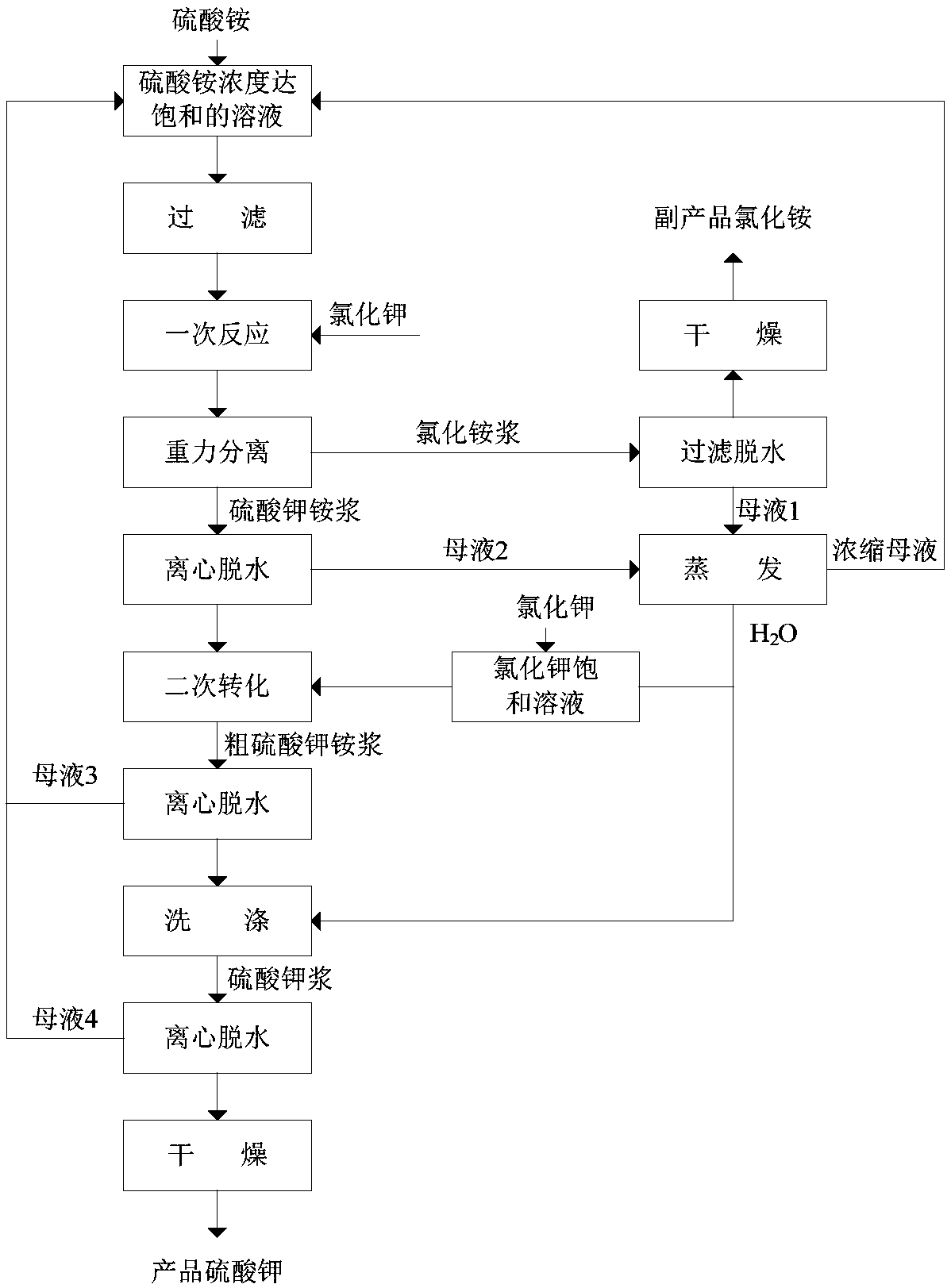

Potassium sulfate preparation system and potassium sulfate preparation method

A preparation system, technology of potassium sulfate, applied in the field of preparation system of potassium sulfate with high recovery rate by double decomposition method, can solve the problems of high equipment material requirements, unstable quality, high energy consumption of evaporation, easy control of conditions and simple technology , the effect of reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] One reaction is carried out in one reaction unit. At room temperature, add ammonium sulfate solid into the salt tank and dissolve it in water. After mixing for 20 minutes, prepare a solution in which the concentration of ammonium sulfate reaches saturation, and filter to remove insoluble matter. With the molar ratio of ammonium sulfate and potassium chloride as the ratio of 1:0.9, add saturated ammonium sulfate solution and industrial grade potassium chloride solid into the reaction crystallizer to react and crystallize. The reaction crystallization time is 20min. The full reaction in the solution is completed, and the slurry in the reactor is ready for use. The primary yield of potassium sulfate in this operation is 90%.

[0025] The slurry (with a solid content of 17%) of the primary reaction unit is pumped into the gravity separation unit through a pump, and the gravity separation is carried out through the gravity separator of the gravity separation unit. The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com