Preparation process of nanometer titanium dioxide or synthetic compound thereof

A nano-titanium dioxide and titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of particle size and purity, which are difficult to achieve, stay, and difficult to mass-produce.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The above-mentioned technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

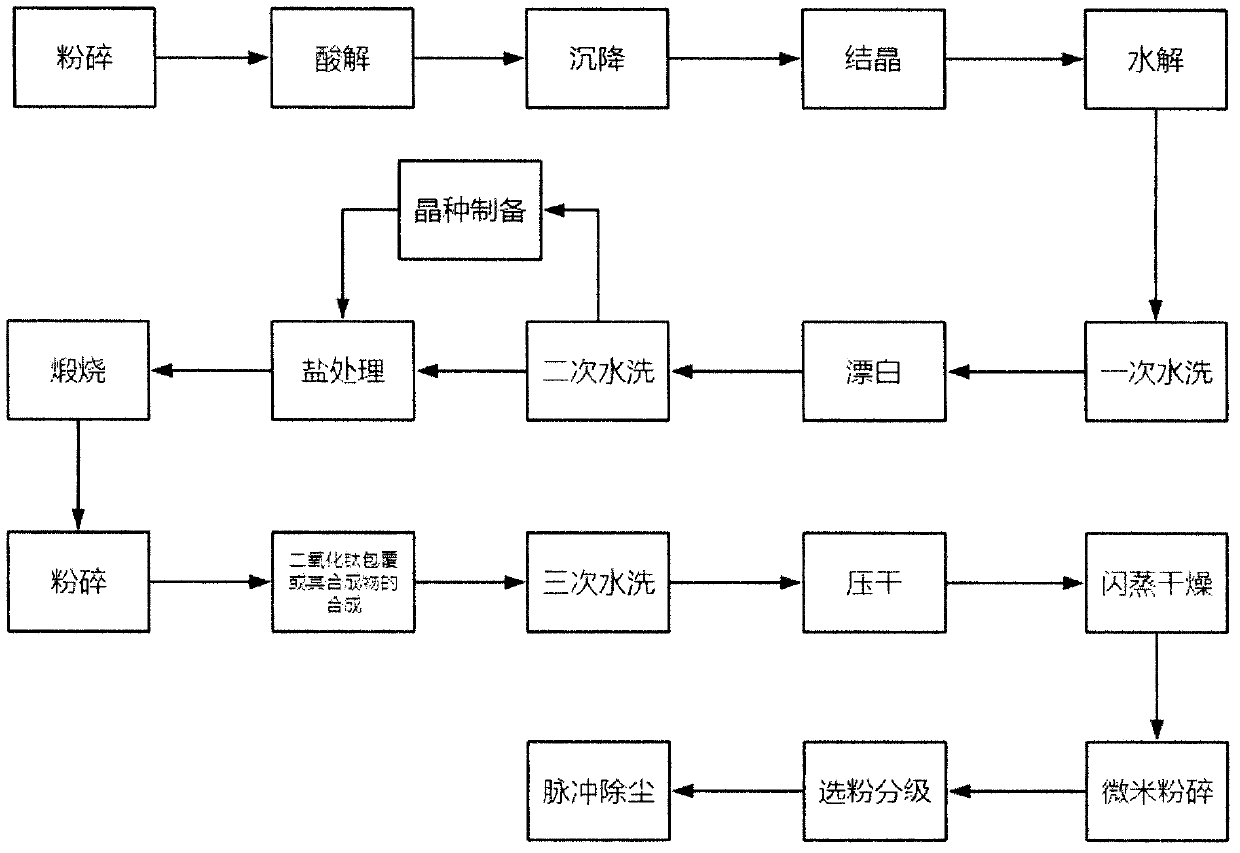

[0101] A preparation process of nano-titanium dioxide or its composite, comprising: step 1, pulverization; step 2, acidolysis; step 3, sedimentation; step 4, crystallization; step 5, hydrolysis; step 6, one-time washing; step 7, bleaching ; Step 8, washing twice; Step 9, preparation of seed crystals; Step 10, salt treatment; Step 11, calcining; Step 12, pulverizing; Step 13, synthesis of titanium dioxide or its composite; 15. Pressure drying; Step 16, flash drying; Step 17, micron crushing; Step 18, powder selection and classification; Step 19, pulse dust removal.

[0102] Step 5: injecting the treated crystal seeds into a hydrolysis tank for hydrolysis, and the titanyl sulfate in the titanium liquid is hydrolyzed by induction of active crystal seeds under heating conditions to produce hydrated titanium dioxide with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com