Instant tea granules and preparation method thereof

A technology for instant tea and granules, applied in the directions of tea, tea extraction, food science, etc., can solve the problems of improving the fluidity and cold solubility of instant tea, and achieve good fluidity and instant solubility, smooth granule surface and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

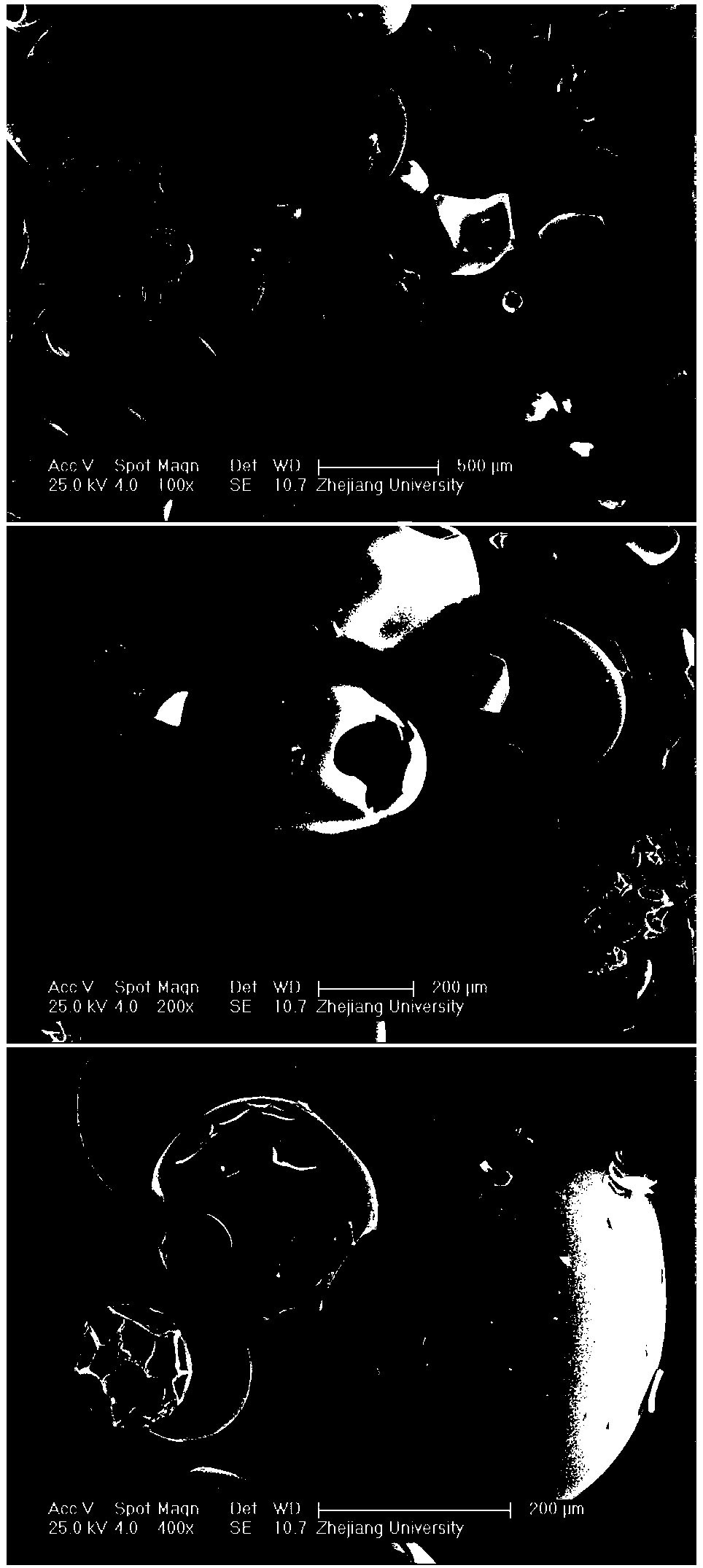

Embodiment 1

[0031] Weigh 1 kg of green tea raw material, extract according to the extraction time of 90 minutes, material-to-liquid ratio of 1:22, and extraction temperature of 80°C to obtain the extraction solution, centrifugally filter the extraction solution, pass through the membrane, and use a thin film flash evaporator to dilute the tea soup The solid content is concentrated to 20%. Weigh a certain mass of concentrated liquid respectively, and the addition ratio of maltodextrin is 50%

[0032] (w / w), be prepared into the material that gross mass is 50kg 70% concentration, adjust material temperature 15 ℃, add CO 2 The concentration ratio is 1:2 (v / v), spray drying after fully mixing, the air inlet temperature is 180°C, and instant tea granules are obtained, which are tested by GB / T8304-2013, QB / T 4067-2010 and other methods: moisture content 5.33±0.37%, average particle size 370.5μm, bulk density 0.16±0.01g / ml, CI index 15.18±3.22, dissolved in cold water within 30s, dissolved in h...

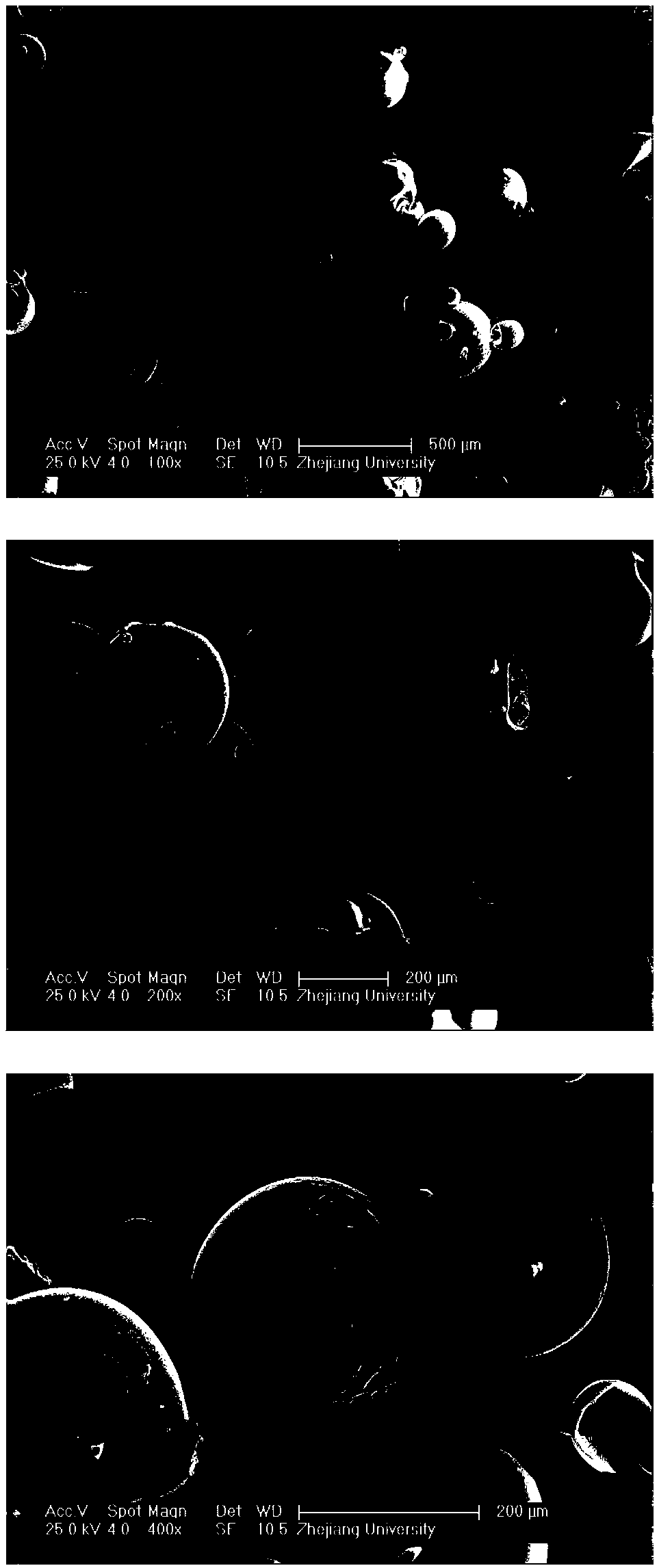

Embodiment 2

[0034] Weigh 1 kg of green tea raw material, extract according to the extraction time of 90 minutes, material-to-liquid ratio of 1:24, and extraction temperature of 90°C to obtain the extraction solution, centrifugally filter the extraction solution, pass through the membrane, and use a thin film flash evaporator to dilute the tea soup The solid content is concentrated to 20%. Weigh a certain mass of concentrated liquid respectively, add maltodextrin at a ratio of 25% (w / w), and prepare a material with a total mass of 50kg at a concentration of 50%, adjust the temperature of the material at 10°C, and add CO 2 The concentration ratio is 1:2 (v / v), mixed thoroughly and then spray-dried, and the air inlet temperature is 200°C to obtain instant tea granules, which are tested by GB / T 8304-2013, QB / T 4067-2010 and other methods: moisture The content is 4.21±0.26%, the average particle size is 221.4μm, the bulk density is 0.23±0.00g / ml, the CI index is 15.84±1.18, it dissolves in col...

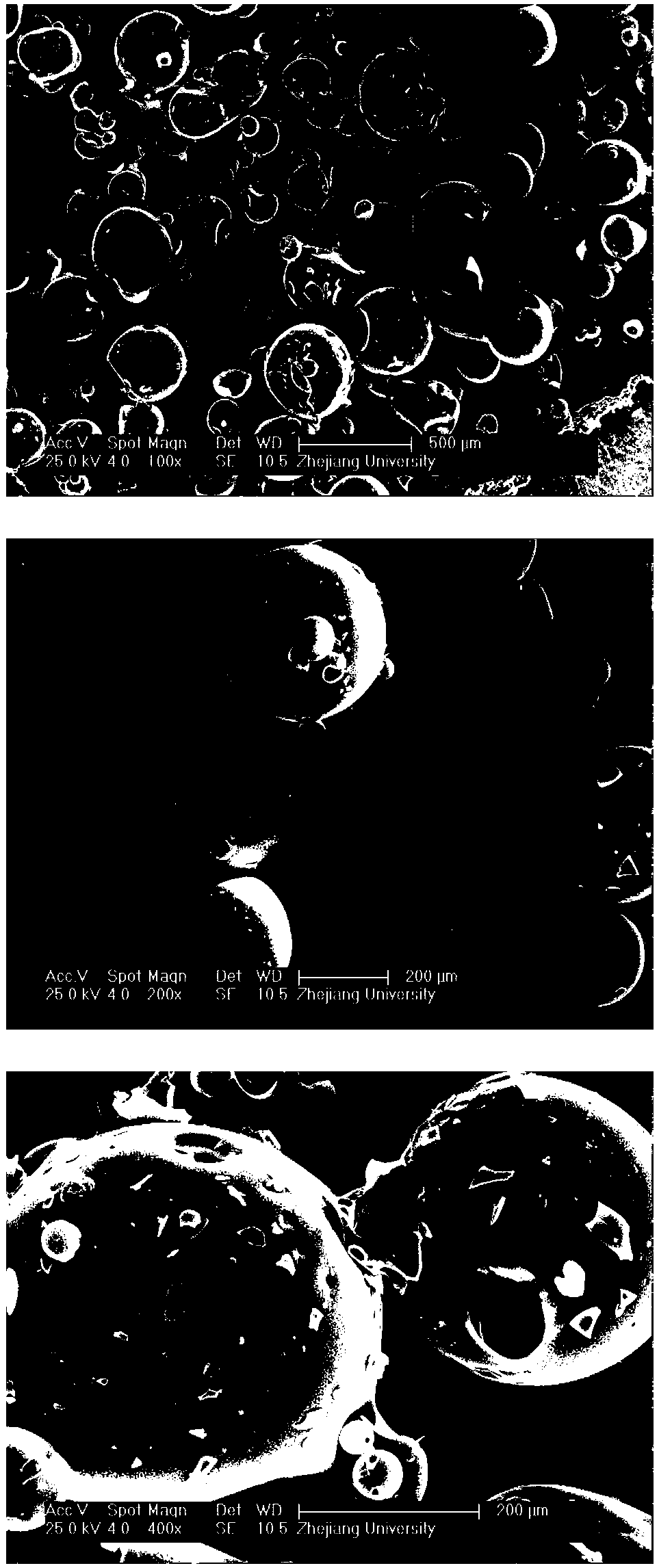

Embodiment 3

[0036] Weigh 1 kg of green tea raw material, extract according to the extraction time of 90 minutes, material-to-liquid ratio of 1:24, and extraction temperature of 90°C to obtain the extraction solution, centrifugally filter the extraction solution, pass through the membrane, and use a thin film flash evaporator to dilute the tea soup The solid content is concentrated to 20%. Weigh a certain mass of concentrated solution, add maltodextrin at a ratio of 125% (w / w), and prepare a material with a total mass of 50kg at a concentration of 50%, adjust the temperature of the material at 10°C, and add CO 2 The concentration ratio is 1:2 (v / v), mixed thoroughly and then spray-dried, and the air inlet temperature is 200°C to obtain instant tea granules, which are tested by GB / T 8304-2013, QB / T 4067-2010 and other methods: moisture The content is 5.32±0.06%, the average particle size is 327.0μm, the bulk density is 0.10±0.00g / ml, and the CI index is 24.38±0.53. It dissolves in cold wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com