Method for treating degradation-resistant organic wastewater by using Fenton oxidation intensified supercritical water oxidation method

A technology of organic wastewater and Fenton oxidation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as unreachable effects, reduce reaction conditions, and improve degradation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

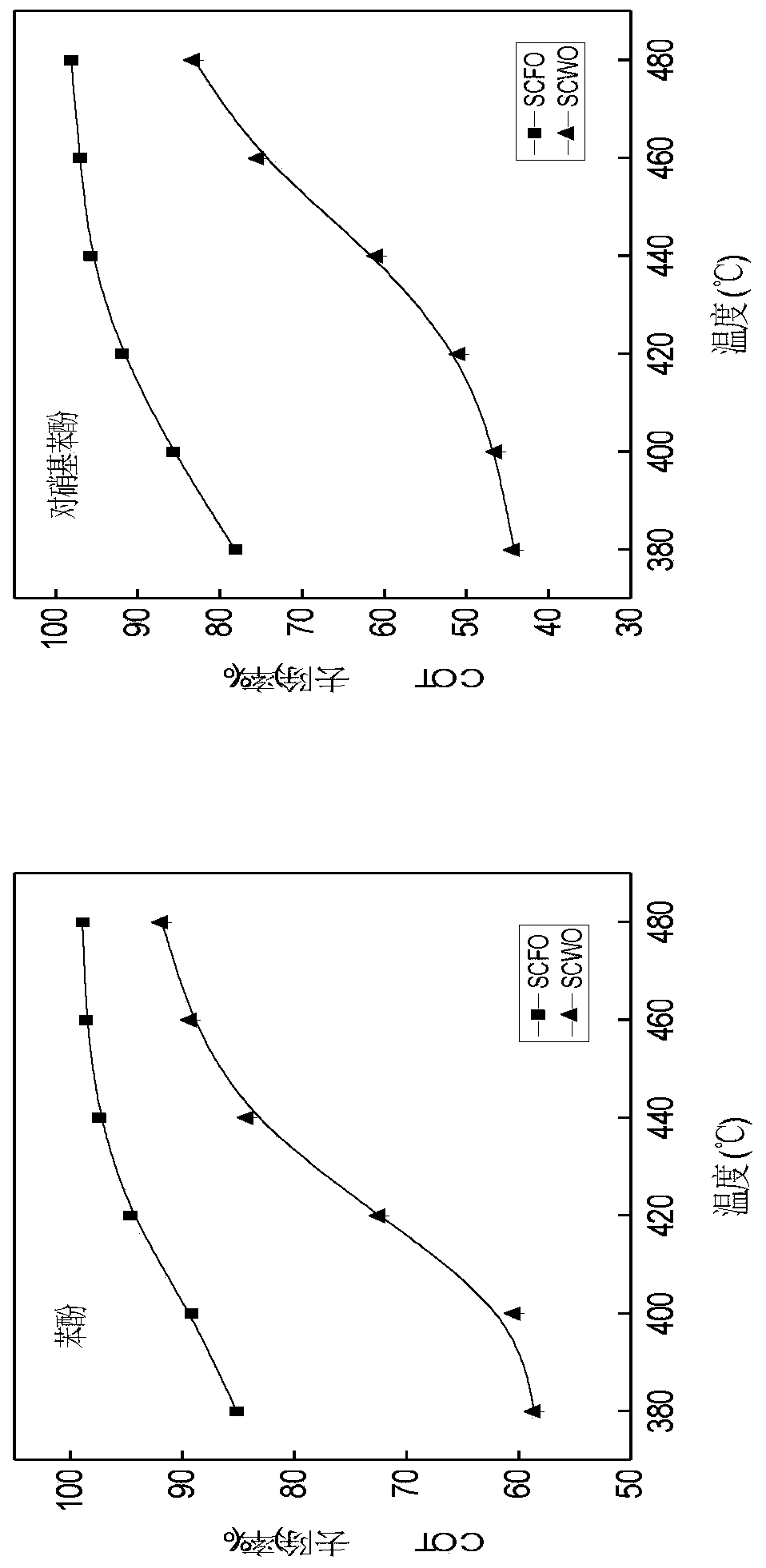

[0027] The initial TOC concentration of the used phenol waste water of the present invention and p-nitrophenol waste water is 1000mg / L; FeSO 4 ·7H 2 O(AR,≥98%) formulated as Fe 2+ The aqueous solution with a concentration of 1.5mg / L is used as a catalyst; 30wt% hydrogen peroxide is used as an oxidant; the pressure is set to 23MPa, and 98% concentrated sulfuric acid solution is prepared into a 0.01mol / L solution to adjust the pH, and the pH is adjusted to 3.0; the temperature is set separately 380°C, 400°C, 420°C, 440°C, 460°C, 480°C; the injection flow rate is 2mL / min, and the corresponding residence time is 217.3s.

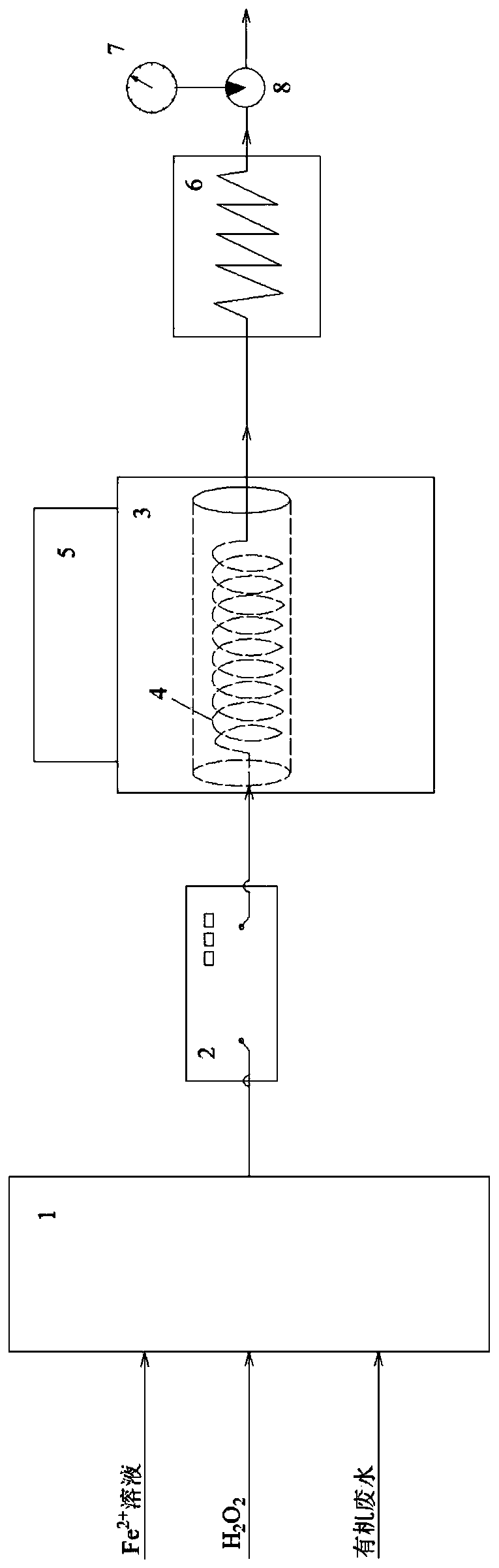

[0028] Phenol wastewater, p-nitrophenol wastewater, oxidant, and ferrous ion solution were respectively passed through a low-pressure gradient mixer in a volume ratio of 9:5:10, and then mixed by a high-pressure constant-flow pump into a stainless steel pipe (outer diameter 1 / 8 ", with an inner diameter of 1.5mm), the tubular reactor is placed in a box-type res...

Embodiment 2

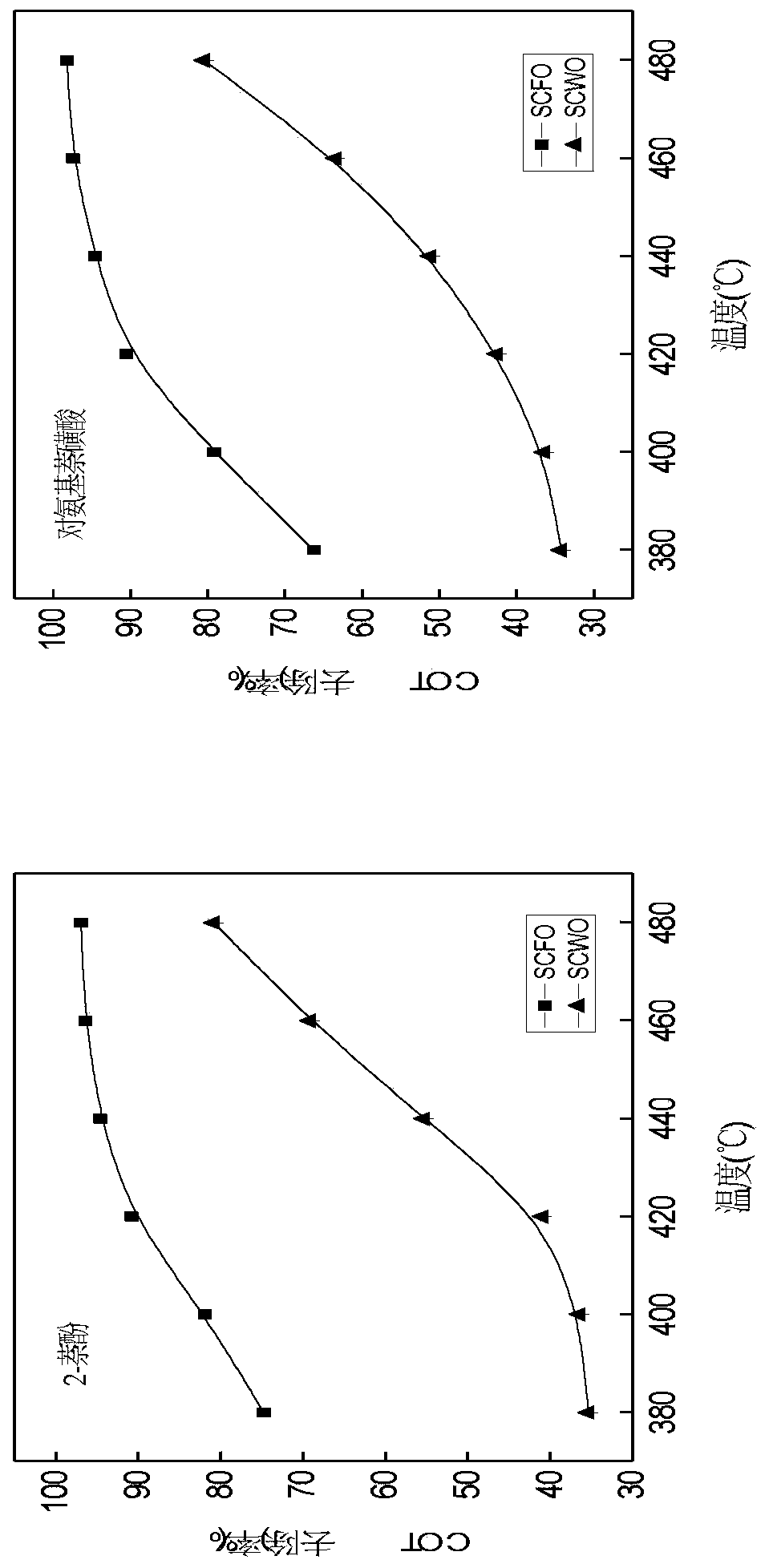

[0034] The initial TOC concentration of 2-naphthol wastewater and p-aminonaphthalenesulfonic acid wastewater is 1000mg / L; FeSO 4 ·7H 2 O(AR,≥98%) formulated as Fe 2+ A solution with a concentration of 1.5mg / L is used as a catalyst; 30wt% hydrogen peroxide is used as an oxidant; the pressure is set to 23MPa, and 98% concentrated sulfuric acid solution is prepared into a 0.01mol / L solution to adjust the pH, and the pH is adjusted to 3.0; the temperature is set separately 380°C, 400°C, 420°C, 440°C, 460°C, 480°C; the injection flow rate is 2mL / min, and the corresponding residence time is 217.3s.

[0035] Naphthol wastewater, p-aminonaphthalenesulfonic acid wastewater, oxidant, and ferrous ion solution were respectively passed through a low-pressure gradient mixer at a volume ratio of 9:5:10, and then mixed by a high-pressure constant-flow pump into a stainless steel pipe (outer diameter 1 / 8", inner diameter 1.5mm), the tubular reactor is placed in a box-type resistance furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com