High-precision fiber optic tapered equipment

A high-precision, optical fiber technology, applied in the field of precision processing equipment manufacturing and high-precision optical fiber taper equipment, can solve problems such as inflexible operation and complexity, and achieve the effect of ensuring stretching effect, good forming effect and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

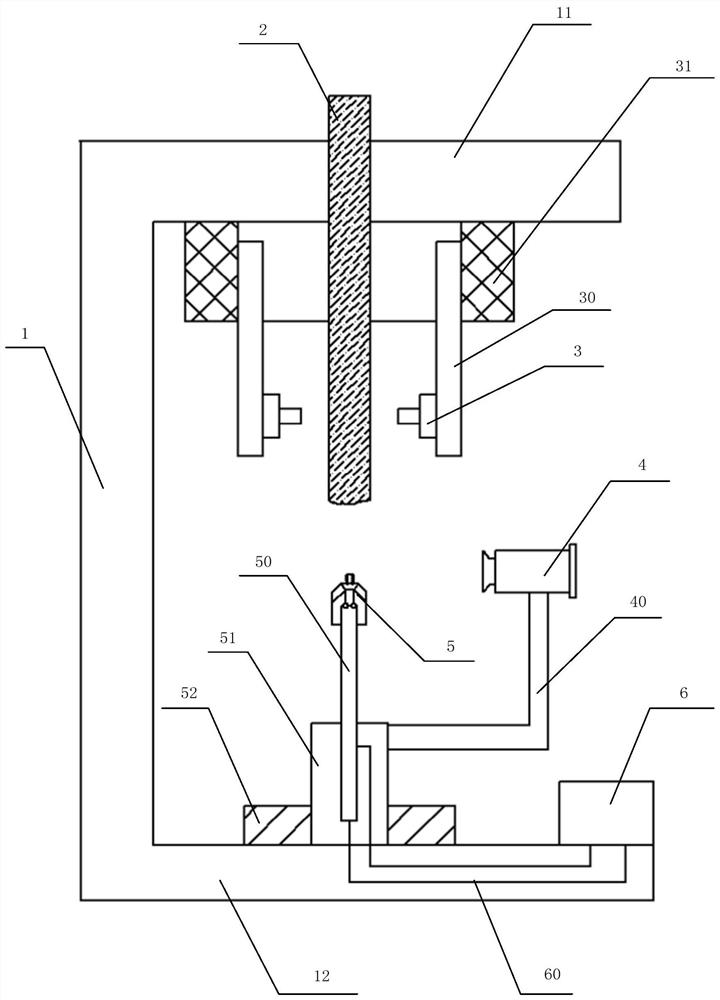

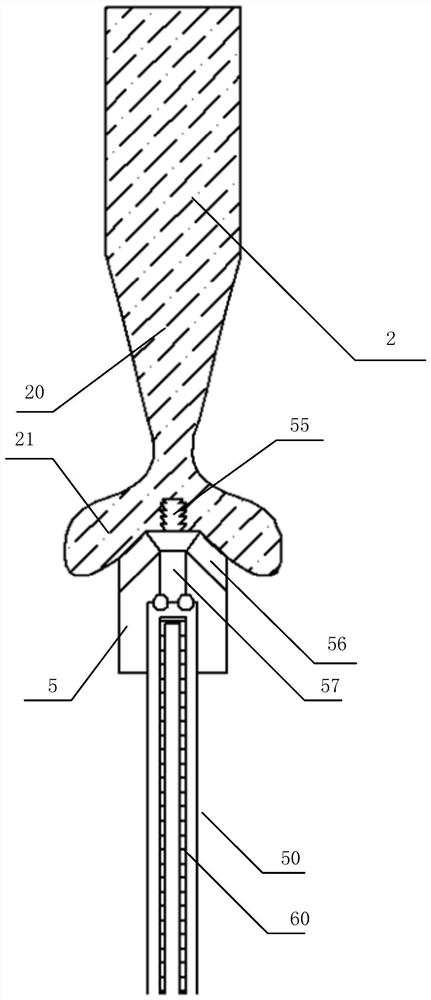

[0031] Such as figure 1 Shown is the structural representation of the high-precision optical fiber tapering equipment of the embodiment of the present invention; And in combination figure 2 .

[0032] The high-precision optical fiber tapering equipment of the embodiment of the present invention includes: an electrode heater 3, an optical fiber 2, a suspension frame 11 and a base 12; generally, the embodiment of the present invention also includes: a support frame 1; the suspension frame 11 and the The base 12 is respectively fixed on both ends of the support frame 1 so that the support frame 1 has a C-shaped structure. This can also ensure the structural strength and stability of the entire device.

[0033] The upper end of the optical fiber 2 is installed on the suspension frame 11, and the optical fiber 2 is perpendicular to the horizontal plane; that is, it is on the gravity line, or the vertical line. Generally speaking, the connecting part of the optical fiber 2 needs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com