A method for continuously and rapidly hydrolyzing 2-hydroxy-4-methylthiobutyronitrile to synthesize methionine hydroxyl analogs

A technology of methylthiobutyronitrile and methionine hydroxyl group is applied in the chemical industry, and can solve the problems of hydration and hydrolysis reaction not being easy to complete, dark color of methionine hydroxyl analogs, long reaction time, etc., so as to reduce raw material polymerization and by-product generation, Increased intermolecular collisions and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

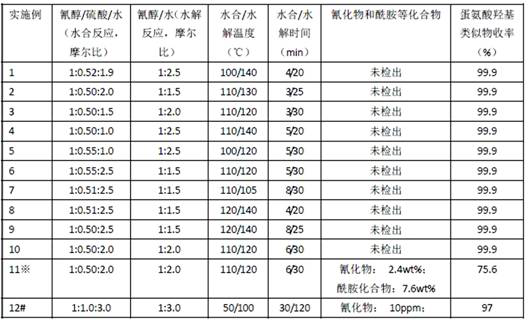

Examples

Embodiment

[0029] 163.995 grams (1.0 mol) of 2-hydroxy-4-methylthiobutyronitrile (cyanohydrin) aqueous solution with a mass percentage of 80 wt% and 52.0 grams (0.52 moles) of sulfuric acid with a mass percentage of 98 wt% were simultaneously measured The pump pumps the loaded solid catalyst (SO 4 2- / Fe 2 o 3), the molar ratio of 2-hydroxy-4-methylthiobutyronitrile (cyanohydrin), sulfuric acid and water is 1:0.52:1.90, and the aqueous solution of 2-hydroxy-4-methylthiobutyronitrile is in The flow rate in the microchannel is 9.0 g / min, the flow rate of sulfuric acid in the microchannel is 2.854 g / min, the controlled reaction temperature is 100°C, the reaction pressure is 0.2MPa, and the residence time is 4min (that is, the hydration reaction time is also the reaction time). The time when the liquid flows through the microchannel), the liquid flowing out from the microchannel is 2-hydroxy-4-methylthiobutyramide sulfate solution. 2-Hydroxy-4-methylthiobutanamide sulfate solution and 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com