3D printing photosensitive resin with high precision, low layer thickness and high performance as well as preparation and use methods of 3D printing photosensitive resin

A photosensitive resin, 3D printing technology, applied in the field of 3D printing materials, can solve the problems of inability to achieve higher precision printing, inability to achieve thin layer printing, etc., and achieve the effects of good uniformity, excellent stability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

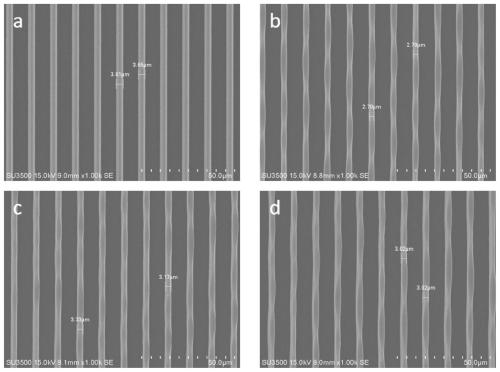

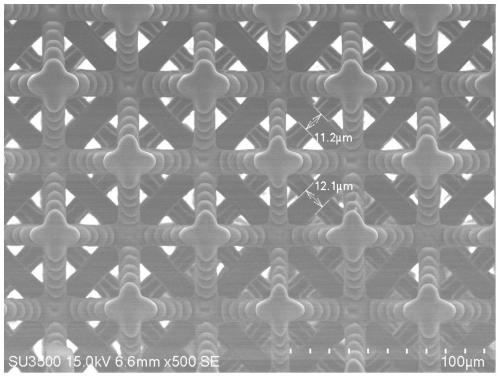

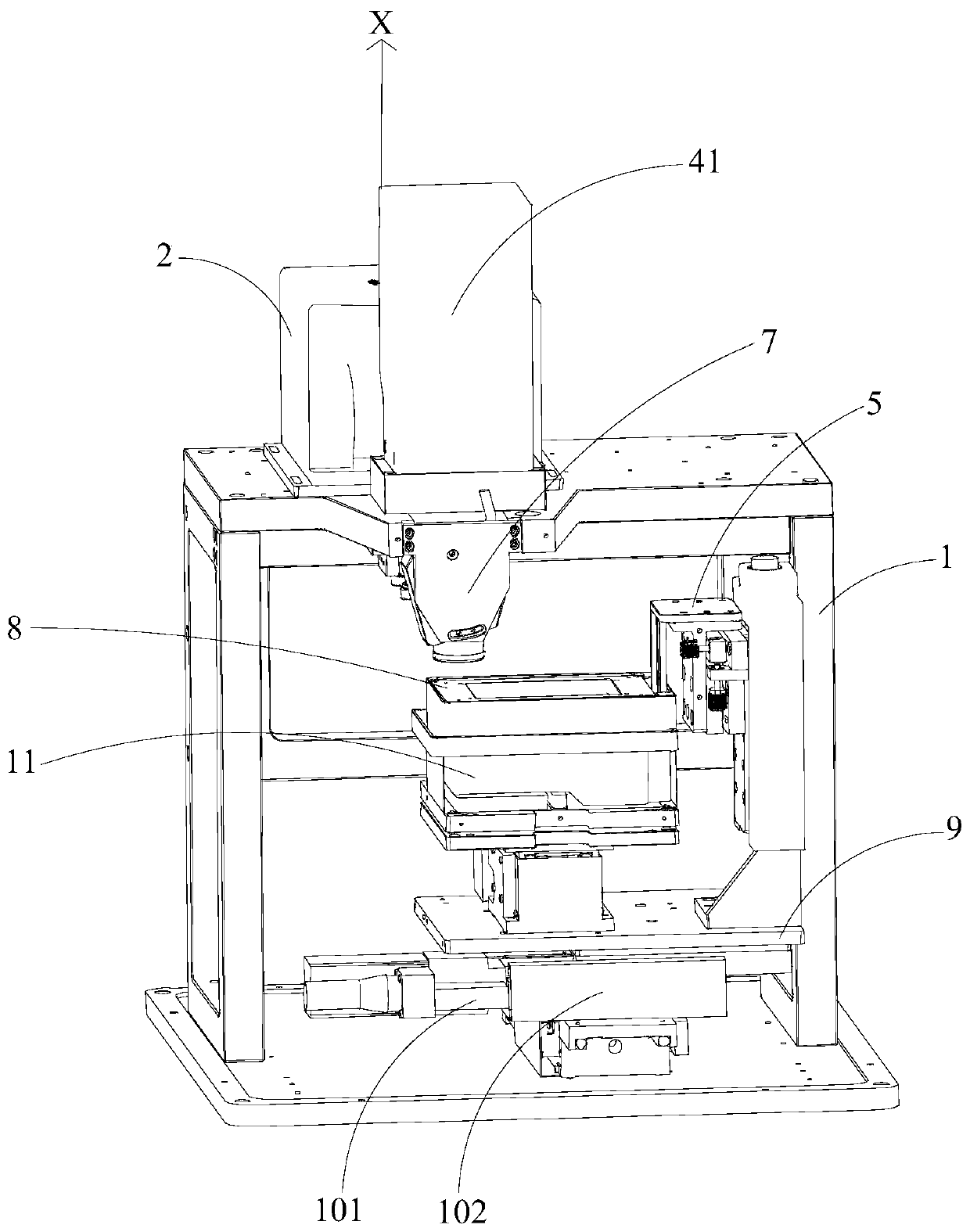

Image

Examples

preparation example Construction

[0063] On the basis of providing high-precision low-layer-thick high-performance 3D printing photosensitive resin, the present invention also provides a preparation method for the 3D printing photosensitive resin, comprising the following steps:

[0064] Dissolve the acrylic resin and POSS resin in the diluent, heat up to 50-60°C, and mix well to obtain the first solution;

[0065] Maintaining at 50-60°C, adding a photoinitiator, a free radical inhibitor, and an ultraviolet absorber to the first solution, and mixing to obtain a second solution;

[0066] Add a leveling agent and a defoamer to the second solution, cool down to room temperature, filter and remove impurities, and obtain a high-precision, low-layer thickness, high-performance 3D printing photosensitive resin.

[0067] Preferably, the filtering is carried out with a filter screen of 1000 mesh to 2000 mesh.

[0068] Furthermore, the present invention also provides a method for using the high-precision, low-layer-thi...

Embodiment 1

[0123] A high-precision, low-layer-thick, high-performance 3D printing photosensitive resin and a preparation method thereof. Among them, according to the mass content of 100%, the high-precision low-layer-thick high-performance 3D printing photosensitive resin contains: 43.23% of acryloylmorpholine; 9.60% of 1,6-hexanediol diacrylate; base) isocyanurate triacrylate 19.21%; novolac epoxy acrylate 9.61%; POSS resin a 14.41%; phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide 1.92%; Free radical piperidinol 0.24%; Sudan I 0.48%; BYK-333 0.58%; TEGO Airex 900 0.72%.

[0124] The preparation method of the high-precision low-layer-thick high-performance 3D printing photosensitive resin is as follows:

[0125] Add 900g of diluent acryloylmorpholine, 200g of 1,6-hexanediol diacrylate, and 400g of tris(2-hydroxyethyl)isocyanurate triacrylate into a 3000mL three-necked flask, and stir for 30min to mix well.

[0126] Add 200 g of novolac epoxy acrylate and 300 g of POSS resin a to the...

Embodiment 2

[0133] A high-precision, low-layer-thick, high-performance 3D printing photosensitive resin and a preparation method thereof. Among them, according to the mass content of 100%, the high-precision low-thickness high-performance 3D printing photosensitive resin contains: 28.63% of acryloyl morpholine; 19.08% of 1,6-hexanediol diacrylate; 19.08% of dipentaerythritol hexaacrylate %; Urethane acrylate 14.31%; Novolak epoxy acrylate 4.77%; POSS resin b 9.54%; Phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide 2.86%; Phenol 0.19%; Anthocyanin 0.72%; BYK-333 0.10%; TEGO Airex 920 0.72%.

[0134] The preparation method of the high-precision low-layer-thick high-performance 3D printing photosensitive resin is as follows:

[0135] Add 600 g of reactive diluent acryloyl morpholine, 400 g of 1,6-hexanediol diacrylate, and 400 g of dipentaerythritol hexaacrylate into a 3000 mL three-necked flask, and stir for 30 minutes to mix well.

[0136] Add urethane acrylate 300g, POSS resin ester b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com