A kind of cationic paraffin emulsion and its preparation method and application

A technology of paraffin emulsion and cation, which is applied in the fields of plant fiber, fiber treatment, textiles and paper making, etc. It can solve the problems of large emulsifier content, affecting the water resistance of paraffin wax, and limiting the use range of emulsified paraffin wax, so as to achieve the effect of ensuring water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

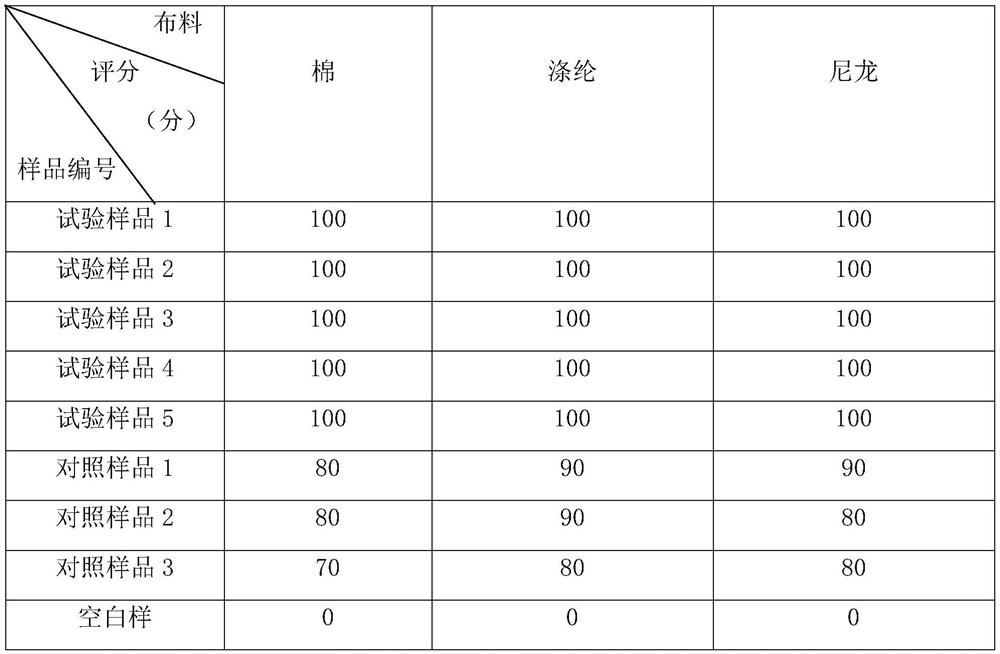

Embodiment 1

[0047] Embodiment 1: A kind of cationic paraffin emulsion, comprising 25.6Kg of distilled water, 20Kg of No. 56 paraffin, 0.7Kg of hydrogenated tallow amine-2EO, 0.1Kg of 99% glacial acetic acid by weight.

[0048] Its preparation method is: with 25.6Kg of distilled water, No. 56 paraffin wax of 20Kg, 0.7Kg of hydrogenated tallow amine-2EO (that is, hydrogenated tallow amine polyoxyethylene ether containing two ethylene oxide EO), 0.1Kg weight percent is Add 99% glacial acetic acid into the pressure emulsification kettle, and seal the pressure emulsification kettle; then directly heat it to 90±10°C, keep it warm for 3 hours until the No. 56 paraffin and hydrogenated tallow amine-2EO in the pressure emulsification kettle are all Melt, then carry out temperature-controlled stirring at a stirring speed of 50r / min. After stirring for 10 minutes, the temperature in the pressure emulsification tank reaches 75°C. At this time, under a homogenizing pressure of 30MPa, the material is ho...

Embodiment 2

[0049] Embodiment 2: a cationic paraffin emulsion, comprising 25.6Kg of pure water, 20Kg of No. 75 microcrystalline paraffin, 1Kg of tallow amine-2EO, 0.1Kg of 99% glacial acetic acid by weight.

[0050] Its preparation method is: with the pure water of 25.6Kg, No. 75 microcrystalline paraffin of 20Kg, the tallow amine-2EO of 1Kg (promptly containing the tallow amine polyoxyethylene ether of two ethylene oxide EOs), 0.1Kg weight percent is Add 99% glacial acetic acid into the pressure emulsification kettle, and seal the pressure emulsification kettle; then directly heat to 102.5±2.5°C, keep warm for 4 hours until the No. 75 microcrystalline paraffin and tallow amine-2EO in the pressure emulsification kettle All melted, followed by temperature-controlled stirring at a stirring speed of 60r / min. After stirring for 12 minutes, the temperature in the pressure emulsification tank reached 95°C. At this time, under a homogenizing pressure of 35MPa, the material was homogenized and dis...

Embodiment 3

[0051] Embodiment 3: a cationic paraffin emulsion, including 25.6Kg of tap water, 20Kg of No. 75 medical white petrolatum, 0.6Kg of dodecylamine-5EO, and 0.03Kg of 99% glacial acetic acid by weight.

[0052] The preparation method is as follows: 25.6Kg of tap water, 20Kg of No. 75 medical white vaseline, 0.6Kg of dodecylamine-5EO (that is, dodecylamine polyoxyethylene ether containing five ethylene oxide EOs), 0.03Kg of weight Add glacial acetic acid with a percentage of 99% into the pressure emulsification kettle, and seal the pressure emulsification kettle; then directly heat it to 75±5°C and keep it warm for 3.5 hours until all the dodecylamine-5EO in the pressure emulsification kettle melts , and then carry out temperature-controlled stirring at a stirring speed of 70r / min. After stirring for 13 minutes, the temperature in the pressure emulsification tank reaches 70°C. At this time, under a homogenizing pressure of 35MPa, the material is homogeneously discharged through a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com