A kind of ball-milled graphene-mofs composite material, its preparation and application

A composite material and graphene technology, applied in the fields of nanomaterial technology and electrochemical sensors, can solve the problems of toxic chemical reagents, the danger of complex preparation processes, etc., and achieve the effects of cost reduction, good electrochemical reactivity, and short reaction cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a ball milled graphene-MOFs composite material, comprising the steps of:

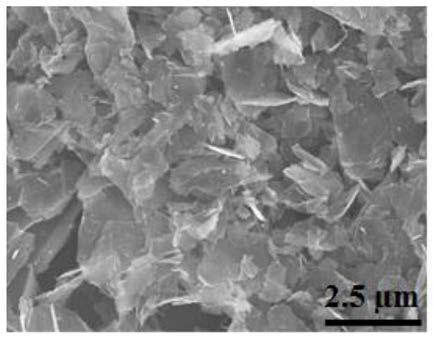

[0037] (1) The graphite powder is peeled off by wet ball milling, and the shear force is dominant in the ball milling peeling process to obtain a mixed system containing graphene nanosheets;

[0038] (2) the mixed system containing graphene nanosheets obtained in step (1) adopts gradient centrifugation to remove unexfoliated graphite in the mixed system, and obtains graphene nanosheets solid;

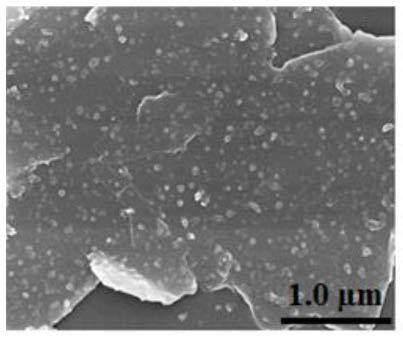

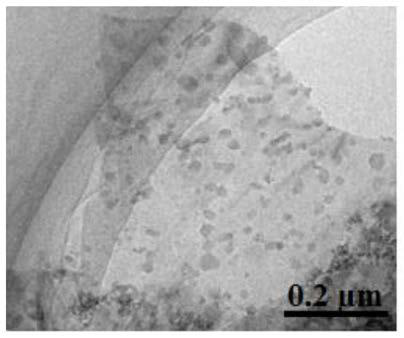

[0039](3) the metal salt dispersed in the organic solvent is mixed with the graphene nano-sheets obtained in step (2), and stirred so that the metal ions in the metal salt are adsorbed on the graphene nano-sheets to obtain the graphene nano-sheets loaded with metal ions piece;

[0040] (4) Mix the graphene nanosheets loaded with metal ions obtained in step (3) with organic ligands, and promote the in-situ synthesis of MOFs on the surface of graphene nanosheets...

Embodiment 1

[0071] A kind of preparation method of ball-milled graphene / Cu-BTC composite material is carried out according to the following steps:

[0072] Disperse 300 mg of 1200 mesh graphite powder and 300 mg of cetyltrimethylammonium bromide powder in 30 ml of aqueous solution containing 15% ethanol, and control the ball milling speed at 300 rpm to ensure that the shear force accounts for Dominance, after 12 hours of ball milling reaction, the graphene nanosheets mixed solution was obtained by exfoliation by ball milling.

[0073] The mixed solution was centrifuged at 2000 rpm for 20 minutes to remove the unexfoliated graphite powder precipitate. Then the obtained solution was centrifuged at 9000 rpm for 20 minutes to obtain a solid, which was repeatedly washed with ethanol and ultrapure water to remove residual cetyltrimethylammonium bromide, and finally air-dried at 60°C.

[0074] 0.7 g of Cu(NO 3 ) 2 ·3H 2 O was uniformly dispersed in 50 ml of DMF solution, then 50 mg of ball-m...

Embodiment 2

[0098] A kind of preparation method of ball-milled graphene / Co-BTC composite material is carried out according to the following steps:

[0099] Disperse 300 mg of 1200 mesh graphite powder and 300 mg of cetyltrimethylammonium bromide powder in 30 ml of aqueous solution containing 15% ethanol, and control the ball milling speed at 300 rpm to ensure that the shear force accounts for Dominance, after 12 hours of ball milling reaction, the graphene nanosheets mixed solution was obtained by exfoliation by ball milling.

[0100] The mixed solution was centrifuged at 2000 rpm for 20 minutes to remove the unexfoliated graphite powder precipitate. Then the obtained solution was centrifuged at 9000 rpm for 20 minutes to obtain a solid, which was repeatedly washed with ethanol and ultrapure water to remove residual cetyltrimethylammonium bromide, and finally air-dried at 60°C.

[0101] 0.85 g Co(NO 3 ) 2 ·6H 2 O was uniformly dispersed in 50 ml of DMF solution, then 50 mg of ball-mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com