Thermal forming wrinkling prediction and control method for a large complex thin-wall titanium alloy component

A control method, titanium alloy technology, applied in the field of basic non-cutting processing or processing of metal plates or tubes, rods or profiles, can solve the problem of poor plasticity, wrinkling of sheet metal, and wrinkling of complex thin-walled titanium alloy parts that are difficult to predict and control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the following examples are given to further illustrate the present invention in detail. It should be pointed out that the specific implementation described here is only used to explain the present invention, and not to limit the present invention.

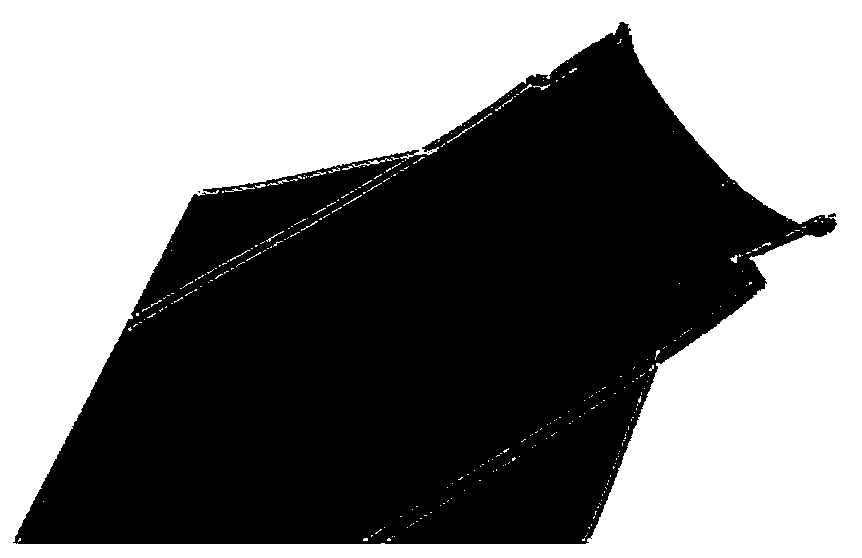

[0086] This method is aimed at the hot forming of large-size and complex TA32 titanium alloy skin parts, and the appearance of the parts is like figure 2 Shown

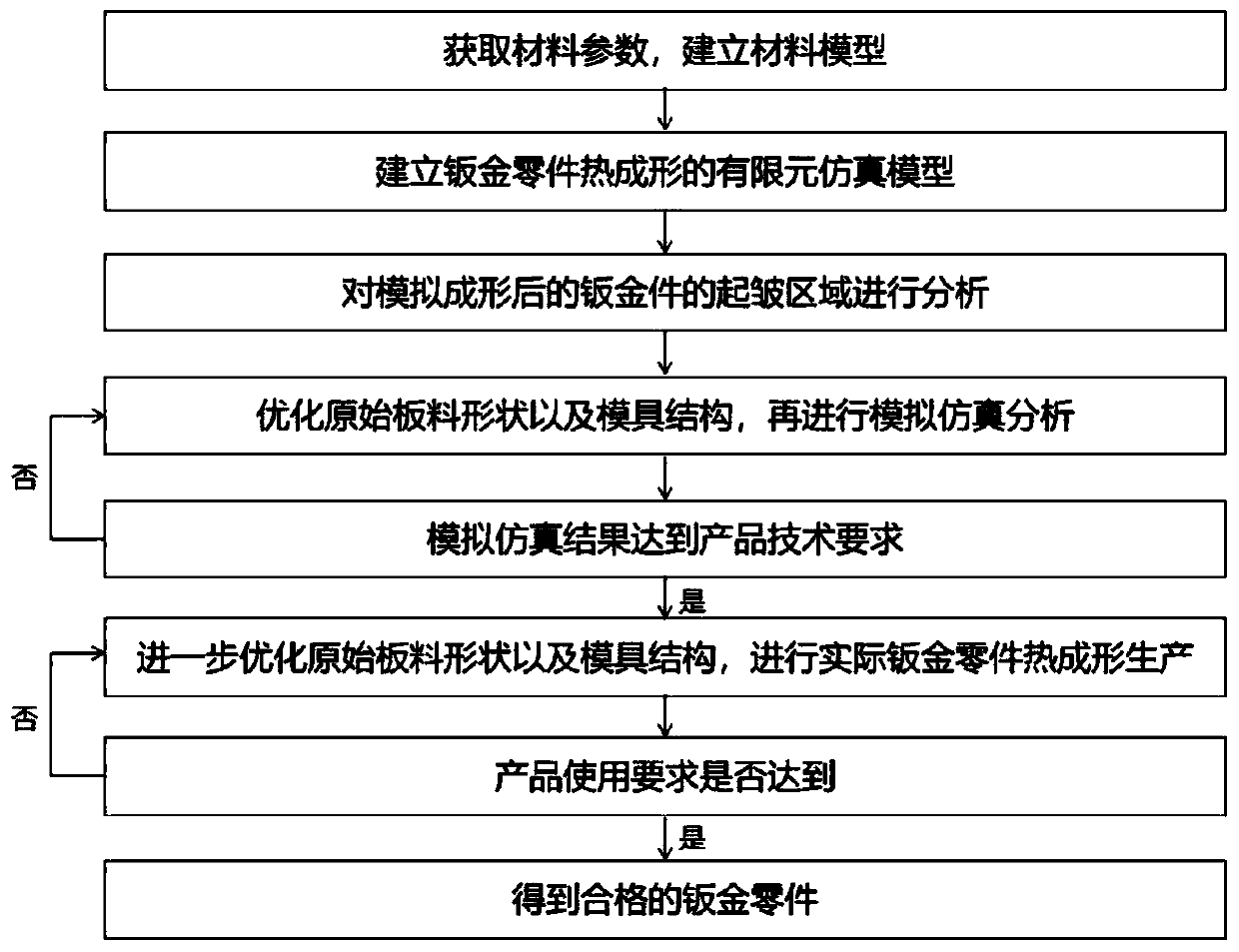

[0087] The following is attached Figure 1-8 Explain in detail the wrinkle prediction and control method of large-size complex titanium alloy skin parts. The method flow chart is as follows figure 1 As shown, the steps are:

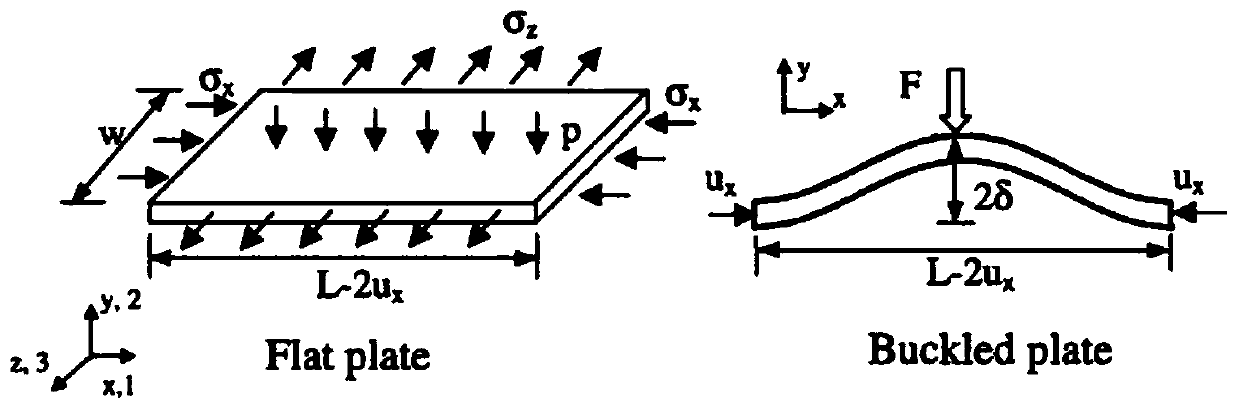

[0088] Step 1. Establish the prediction theory of wrinkle in hot press forming of titanium alloy thin-walled components;

[0089] Step 2: Obtain the material mechanics parameters, combine with the wrinkle prediction theory to obtain the crit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com