Preparation method of surface coating modified lithium battery metal lithium negative electrode

A technology of surface coating and metal lithium, which is applied in the manufacture of battery electrodes, lithium batteries, electrolyte batteries, etc., can solve the problems that hinder the large-scale application of solid electrolytes, and achieve the solution of interface resistance, strong combination, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

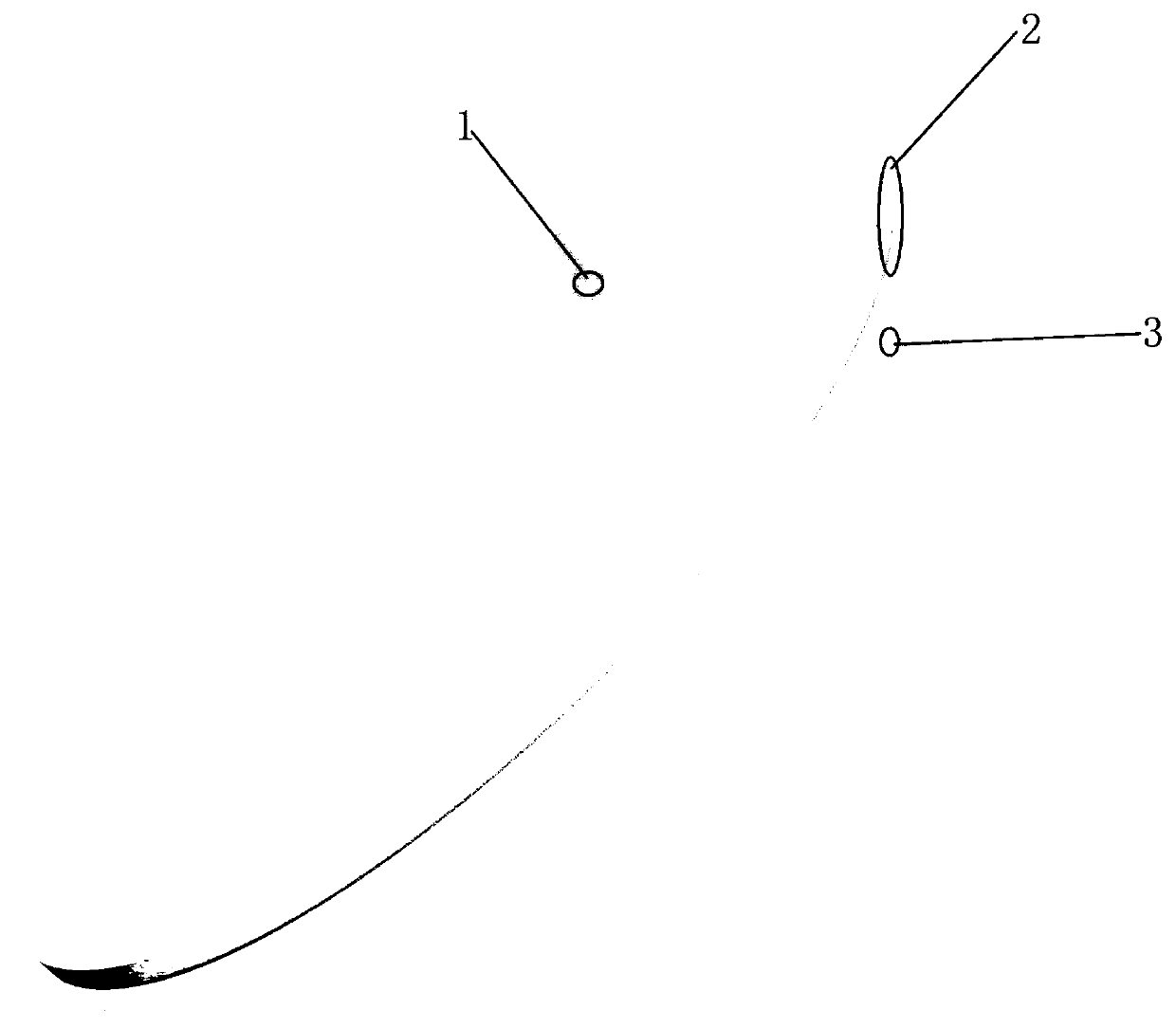

[0026] Such as figure 1 As shown, this embodiment provides a method for preparing a surface-coated and modified lithium battery metal lithium negative electrode, comprising the following steps:

[0027] S1), put the clean and bright metal lithium plate into a closed anti-container, in the argon atmosphere environment with a concentration of 99%, feed 1% nitrogen to react for a certain period of time, and form a layer of 1 μm thick on the surface of the metal lithium plate The golden-yellow interface substance oxidizes nitrogen to obtain a surface-modified lithium metal plate;

[0028] S2), the surface of the garnet solid electrolyte (GARNET) is polished and polished to remove impurities;

[0029] S3), the surface-modified lithium metal plate in step S1) and the garnet-type solid electrolyte (GARNET) that removes impurities in step S2) are closel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Interface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com