Method for improving property of microbial fuel cell sensor

A technology of fuel cells and microorganisms, applied in biochemical fuel cells, fuel cells, circuits, etc., can solve the problems that the sensitivity and stability of MFC sensors cannot be fundamentally improved, and the sensing performance declines, and achieve faster in-situ on-line monitoring process, promotes agility and strength, improves proportion and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

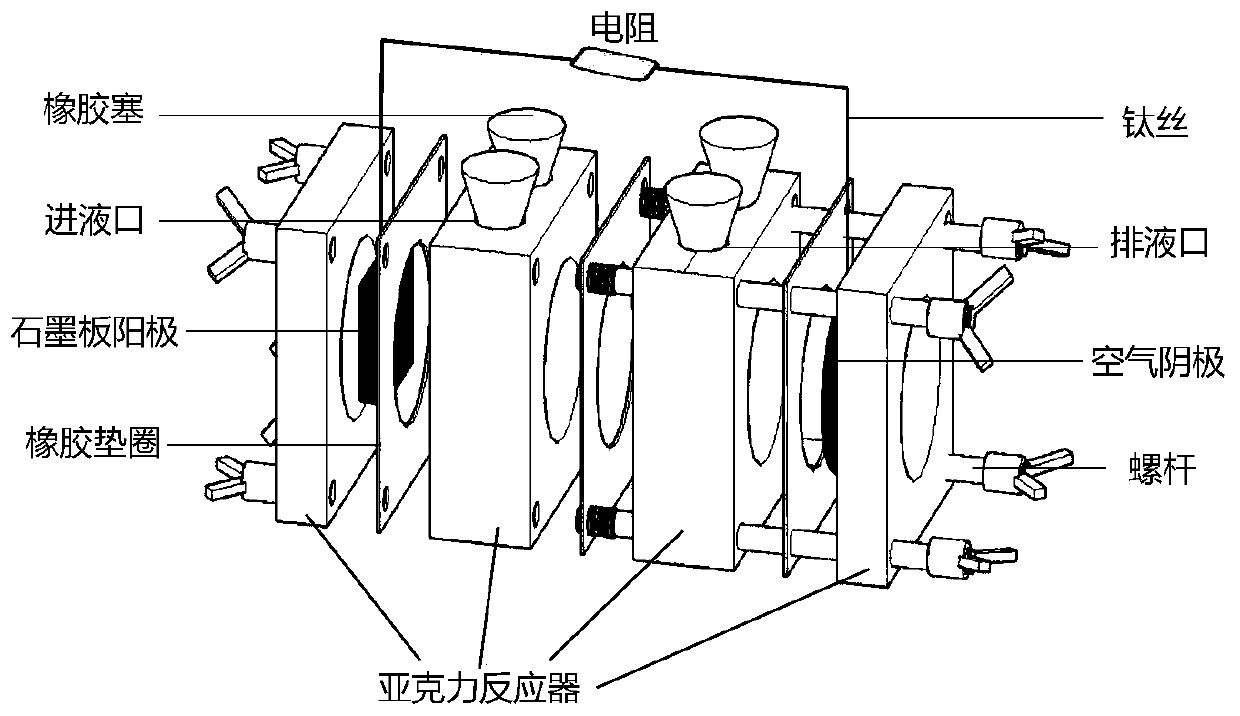

[0047] (I) Construction of the MFC sensor: The MFC sensor is a 28mL cubic reactor, and the anode is a graphite plate with a size of 2cm×2cm×0.5cm. It is polished with sandpaper and soaked in a 1:3 concentrated sulfuric acid / hydrogen peroxide solution for 60s, and then Sonicate with pure water for 10 minutes, and fix the graphite plate with titanium wire after drilling holes. The cathode is selected by using polyvinylidene fluoride (PVDF) binder to mix and bond activated carbon and carbon black powder evenly on the stainless steel mesh, soak in pure water for 15 minutes, and air dry for later use. After fixing the anode and cathode in the reactor, connect the anode and cathode with titanium wire and alligator clips, and connect a 1000Ω resistor externally. The two ends of the external resistance are connected to the data acquisition instrument, and the voltage data at both ends of the external resistance are collected every 1 min.

[0048] figure 1 It is an MFC sensor constru...

Embodiment 2

[0053] Adopt same method to repeat embodiment 1, difference is, select 2mg / L-10mg / L Cu for use in described step (Ⅴ). 2+ solution for highly toxic heavy metal sensing experiments. After the MFC sensor replaces the culture medium, the output voltage rises and after the highest output voltage stabilizes for 2-3 hours, add a certain volume of Cu to the culture medium 2+ standard solution. Two hours after the sensing experiment, the MFC sensor culture medium was replaced with a fresh culture medium, and the recovery of the MFC output voltage signal was observed 4 hours after the culture medium was replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com