Preparation method for graphene/ conductive polymer anode for microbial fuel cell

A conductive polymer, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low power generation efficiency, improve power generation performance, good biocompatible stability and electrochemical activity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

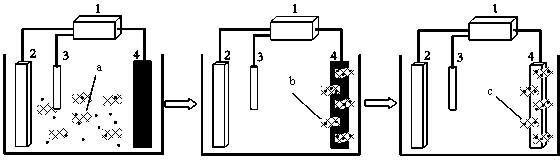

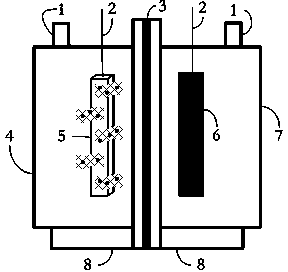

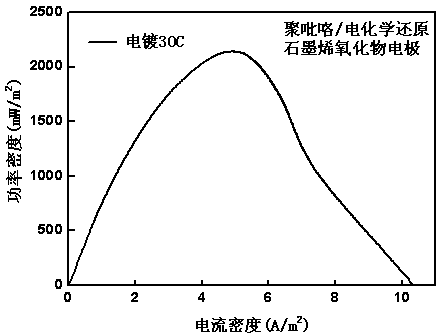

[0022] Such as figure 1 As shown, the schematic diagram of the production process of the battery anode, in the figure 1 is the electrochemical workstation, 2 is the counter electrode, 3 is the reference electrode, 4 is the working electrode; where a refers to the mixed solution (pyrrole monomer and graphene oxide suspension aqueous solution), b refers to polypyrrole / graphene oxide composite film (constant voltage electropolymerization), c refers to polypyrrole / electrochemically reduced graphene oxide composite film (cyclic voltammetry reduction). Prepare the anode as follows:

[0023] (1) Dissolve 200 mg of graphene oxide in 40 mL of deionized water to a concentration of 5 mg·mL -1 aqueous suspension of graphene oxide. Then 8 mmol of pyrrole monomer was added to the graphene oxide aqueous suspension solution to prepare a mixed solution, and the concentration of the conductive polymer monomer in the mixed solution was 0.2 mol L -1 , after magnetic stirring at room temperatur...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that the electroplating amount is 60°C during the polymerization modification process of anodic constant voltage electroplating. Other conditions are all identical with specific embodiment 1. At this time, the maximum power density of the battery reaches 3351 mW / m 2 (See Figure 4 ).

Embodiment 3

[0032] The difference between this embodiment and Example 1 is that the anode is an unmodified pretreated graphite felt electrode. Other conditions are all identical with specific embodiment 1. The microbial fuel cell anode in this embodiment is the same as that in Embodiment 1. At this time, the maximum power density of the battery is only 180 mW / m 2 (See Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com