A combined low-voltage household connection line dedicated wall brazing

A combined, low-pressure technology, applied in anti-corrosion coatings, electrical components, coatings, etc., can solve the problems of easy rust and corrosion of wall brazing, and achieve the effects of preventing rust or corrosion, increasing hydrophobicity, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

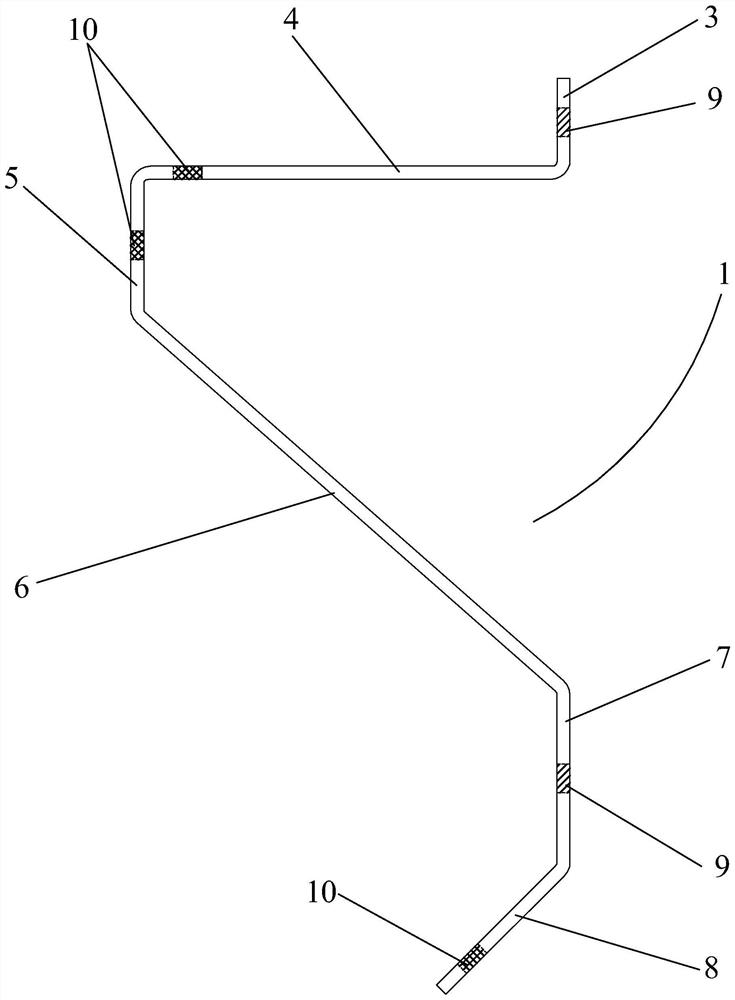

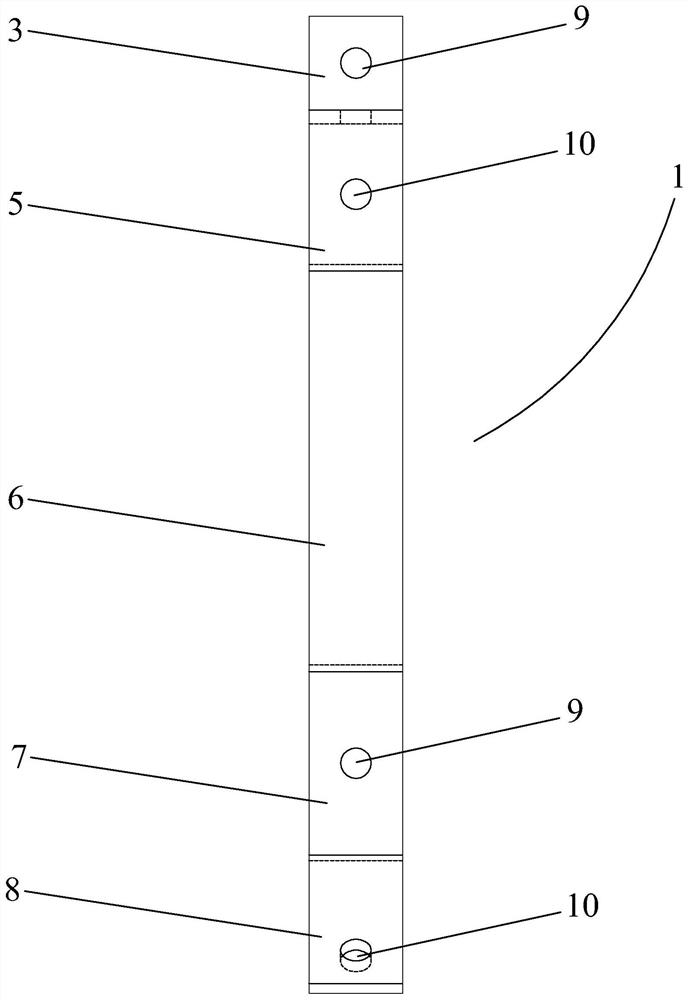

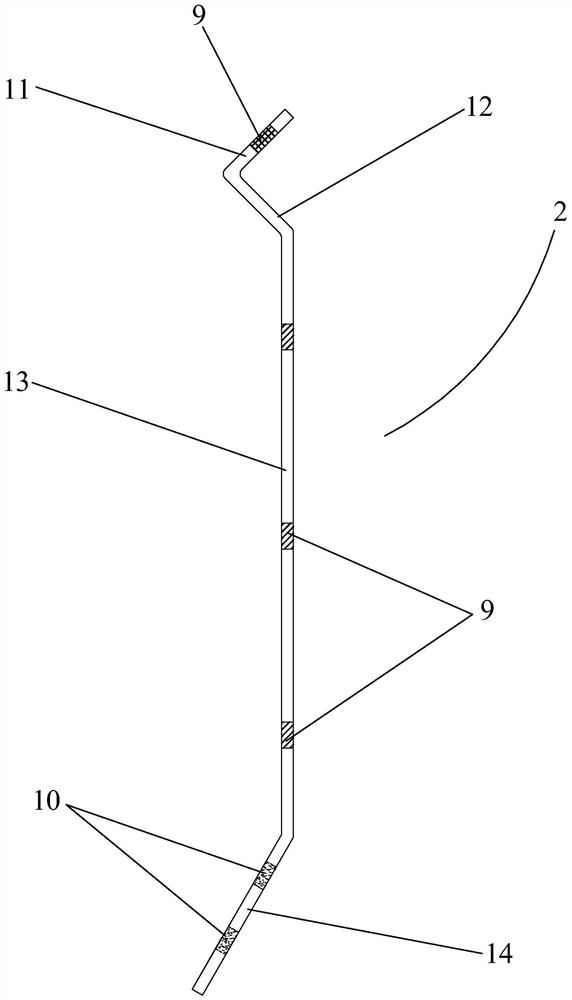

[0047] Embodiment 1: A combined low-voltage household connection line dedicated wall drill, including a bow-shaped bracket 1 and a pull-up bracket with eyes 2, and the bow-shaped bracket 1 and the pull-up bracket 2 with eyes are both punched and folded by flat steel ,Such as Figure 1-2 As shown, the bow-shaped bracket 1 is divided into a first steel segment 3, a second steel segment 4, a third steel segment 5, a fourth steel segment 6, a fifth steel segment 7 and a sixth steel segment 8, the first The steel section 3 and the third steel section 5 are respectively connected with the two ends of the second steel section 4, and bent 90° in different directions, the fourth steel section 6 and the sixth steel section 8 are respectively connected with the two ends of the fifth steel section 7 End connection, bending 130°-135° in the same direction, preferably 131°, the third steel segment 5 is connected to the other end of the fourth steel segment 6, and bent 130°-135° to the secon...

Embodiment 2

[0054] Embodiment 2: the preparation method of unsaturated polyester acrylate hydrophobic coating comprises the following preparation steps:

[0055] (1) Mix 31.5g of phthalic anhydride, 24.8g of sebacic acid, and 27.6g of ethylene glycol to obtain a mixed solution, then add 0.11g of tetrabutyl titanate to the mixed solution, stir and heat, and raise the temperature to 200°C , after 6 hours of reaction, the reaction temperature was lowered to 160°C, and the intermediate product 1 was obtained;

[0056] (2) Add 3.1 g of maleic anhydride to intermediate product 1, then raise the temperature to 214°C, continue the reaction until the acid value is less than 10, and then cool down to 80°C to obtain an unsaturated polyester resin solution;

[0057] (3) Mix 18.4g of perfluorooctyl ethyl acrylate, 20.7g of butyl methacrylate and 12.9g of vinylsulfonic acid into 160g of N,N-dimethylformamide, then add 1.14g of N,N-dimethylformamide under nitrogen protection Oxidize dibenzoyl, place it...

Embodiment 3

[0061] Embodiment 3: the preparation method of unsaturated polyester acrylate hydrophobic coating comprises the following preparation steps:

[0062] (1) Mix 39.5g of phthalic anhydride, 21.7g of sebacic acid, and 29.8g of ethylene glycol to obtain a mixed solution, then add 0.13g of tetrabutyl titanate to the mixed solution, stir and heat, and raise the temperature to 210°C , after 4 hours of reaction, the temperature was lowered to 150°C, and the intermediate product 1 was obtained;

[0063] (2) Add 10.3 g of maleic anhydride to the intermediate product 1, then raise the temperature to 220°C, continue the reaction until the acid value is less than 10, and then cool down to 90°C to obtain an unsaturated polyester resin solution;

[0064] (3) Mix 21.9g of perfluorooctyl ethyl acrylate, 27.3g of butyl methacrylate and 17.4g of vinyl sulfonic acid into 180g of N,N-dimethylformamide, then add 0.18g of N,N-dimethylformamide under nitrogen protection Oxidize dibenzoyl, place it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com