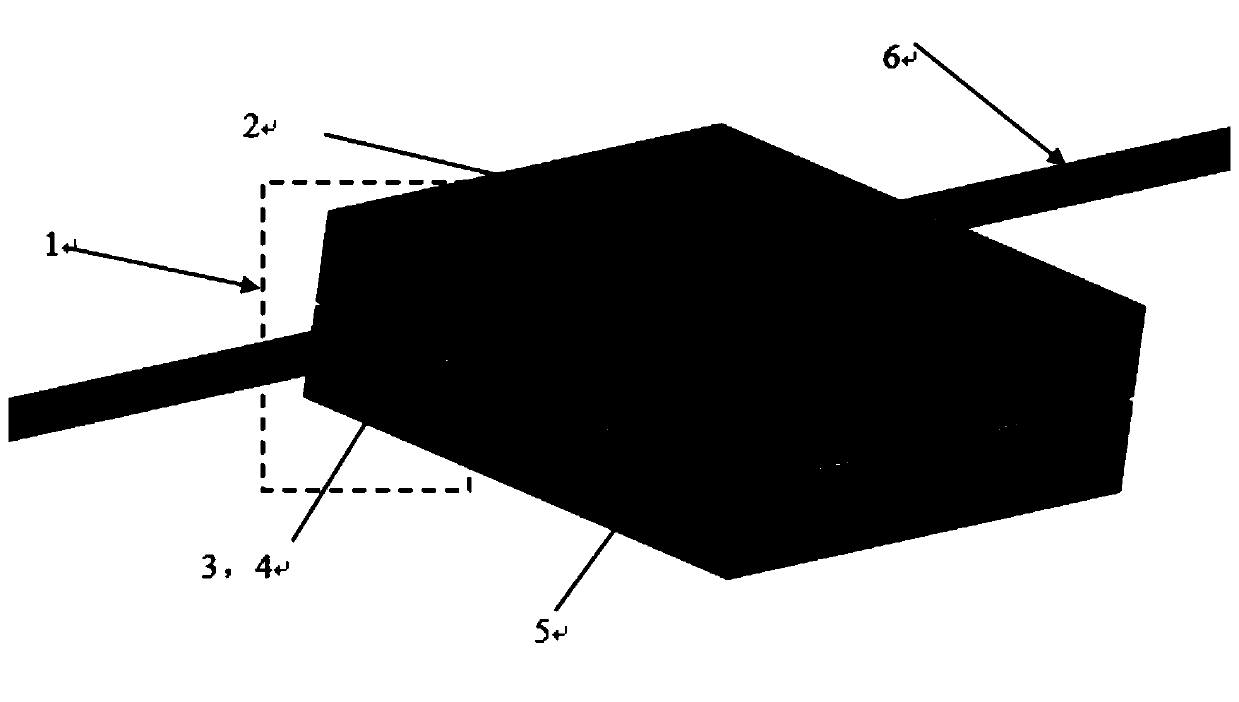

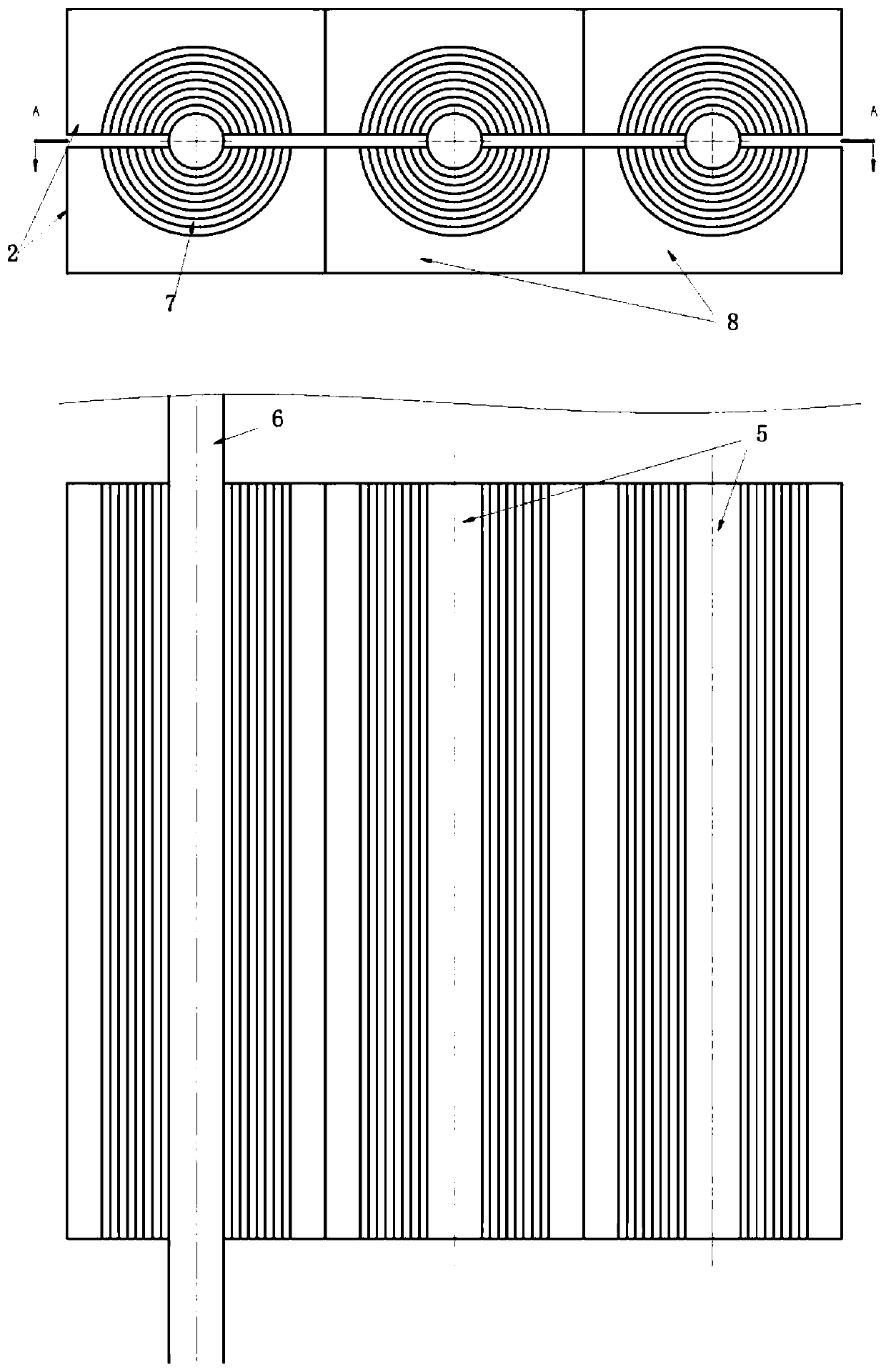

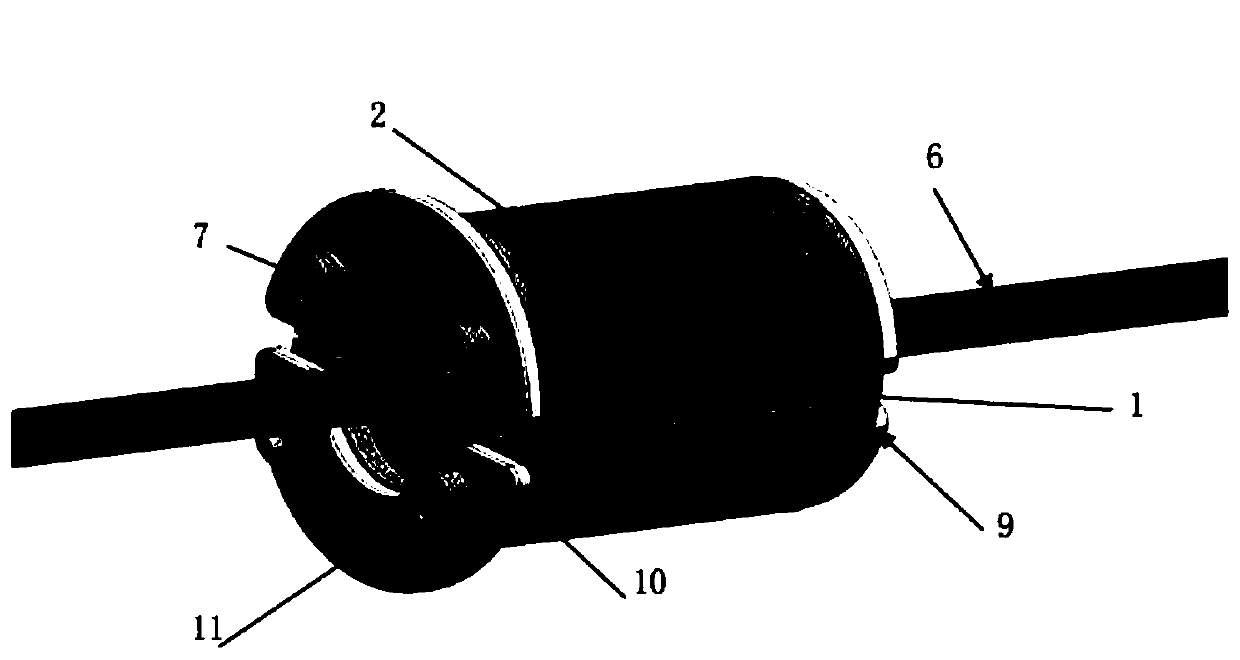

Cable pipeline sealing module

A cable duct and interlayer technology, which is applied in the field of cable duct sealing modules, can solve problems such as poor sealing effect, cable damage, and difficult cable construction, and achieve excellent air aging resistance or oil resistance, good sealing performance, and simple and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The present invention also provides a preparation method of each component material, and the preparation method is a conventional technique in the field. Such as compounding and supplementary processing → raw rubber and compounding agent weighing → mixing → quality inspection.

[0082] The processing method of the base diaphragm is as follows:

[0083] Preparation process: heat refining (adding initiator and vulcanizing agent according to the corresponding proportion of the material) → blanking → vulcanization (vulcanization parameters of standard thickness: 180°C, 6min, pressure 20MPa, the actual vulcanization time of the matrix is calculated according to the equivalent vulcanization time, The pressure is calculated according to the area of the parting surface)→trimming→finished product.

[0084] The preparation methods not mentioned in the present invention are all conventional preparation methods in this field.

[0085] The materials used in the present inventi...

Embodiment 1

[0095] The first aspect of Embodiment 1 provides a cable duct sealing module, and each component material includes the following components by weight percentage.

[0096] 1) By weight percentage, the preparation material of the base comprises the following components:

[0097] 34% of silicon dioxide, 27% of rubber, 21% of aluminum hydroxide, 7.5% of alkane oil, 2.5% of kaolin, 0.3% of pigment, and 7.7% of other additives; said other additives include 4,4'-butylene bis( 6-tert-butyl-3-methylphenol) 0.3%, polyethylene glycol 0.8%, ethylene bisoleamide 0.6%, erucamide 0.2%, titanium dioxide 0.2%, di-tert-butyl peroxyisopropyl Benzene 0.7%, Stearamide 0.6%, Calcium Carbonate 4.3%. The pigment is carbon black.

[0098] 2) In terms of weight percentage, the preparation material of the rubber diaphragm 1 comprises the following components:

[0099] Aluminum hydroxide 29%, kaolin 27.5%, rubber 27%, calcium carbonate 4%, titanium dioxide 4.5%, alkane oil 2.5%, pigment 0.2%, other ad...

Embodiment 2

[0114] The first aspect of Embodiment 2 provides a cable duct sealing module, and each component material includes the following components by weight percentage.

[0115] 1) By weight percentage, the preparation material of the base comprises the following components:

[0116] 33% of silicon dioxide, 25% of rubber, 20% of aluminum hydroxide, 7% of alkane oil, 2% of kaolin, 0.1% of pigment, and 2.5% of other additives; said other additives include 4,4'-butylene bis( 6-tert-butyl-3-methylphenol) 0.2%, polyethylene glycol 0.6%, ethylene bisoleamide 0.5%, erucamide 0.1%, titanium dioxide 0.1%, di-tert-butyl peroxyisopropyl Benzene 0.6%, stearamide 0.4%. The pigment is carbon black.

[0117] 2) In terms of weight percentage, the preparation material of the rubber diaphragm 1 comprises the following components:

[0118] Aluminum hydroxide 29%, kaolin 27%, rubber 26%, calcium carbonate 4%, titanium dioxide 4%, alkane oil 2%, other additives 1%; said other additives are polyisobuty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com