Efficient and stable all-inorganic perovskite battery and preparation method thereof

An inorganic calcium and titanium ore technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor light and heat stability, unstable light and heat of organic cations, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of reactants

[0053] (1-1) Complex PbI 2 -DMSO preparation: 4.84g PbI 2 Dissolve in 15mL DMSO and heat to PbI at 60℃ 2 After completely dissolved, about 35 mL of toluene was slowly added to it, and a white precipitate appeared. After the precipitate was completely precipitated, the precipitate was filtered, placed at room temperature for 3 hours, and dried in vacuum at 60°C for 24 hours.

[0054] (1-2) Complex PbBr 2 -DMSO preparation: 3.85g PbBr 2 Dissolve in 15mL DMSO and heat to PbBr at 60℃ 2 Dissolve completely, then slowly add about 35mL of hot acetone to it, and a white precipitate appears. After the precipitate is completely precipitated, the precipitate is filtered, placed at room temperature for 3 hours and then dried in vacuum at 60°C for 24 hours.

[0055] (1-3) Refining CsI crystal grains: Dissolve 2.73g CsI in 15mL DMSO, slowly heat up until CsI is completely dissolved, then slowly add about 35mL isopropanol to it, and white precipitate appears. Wh...

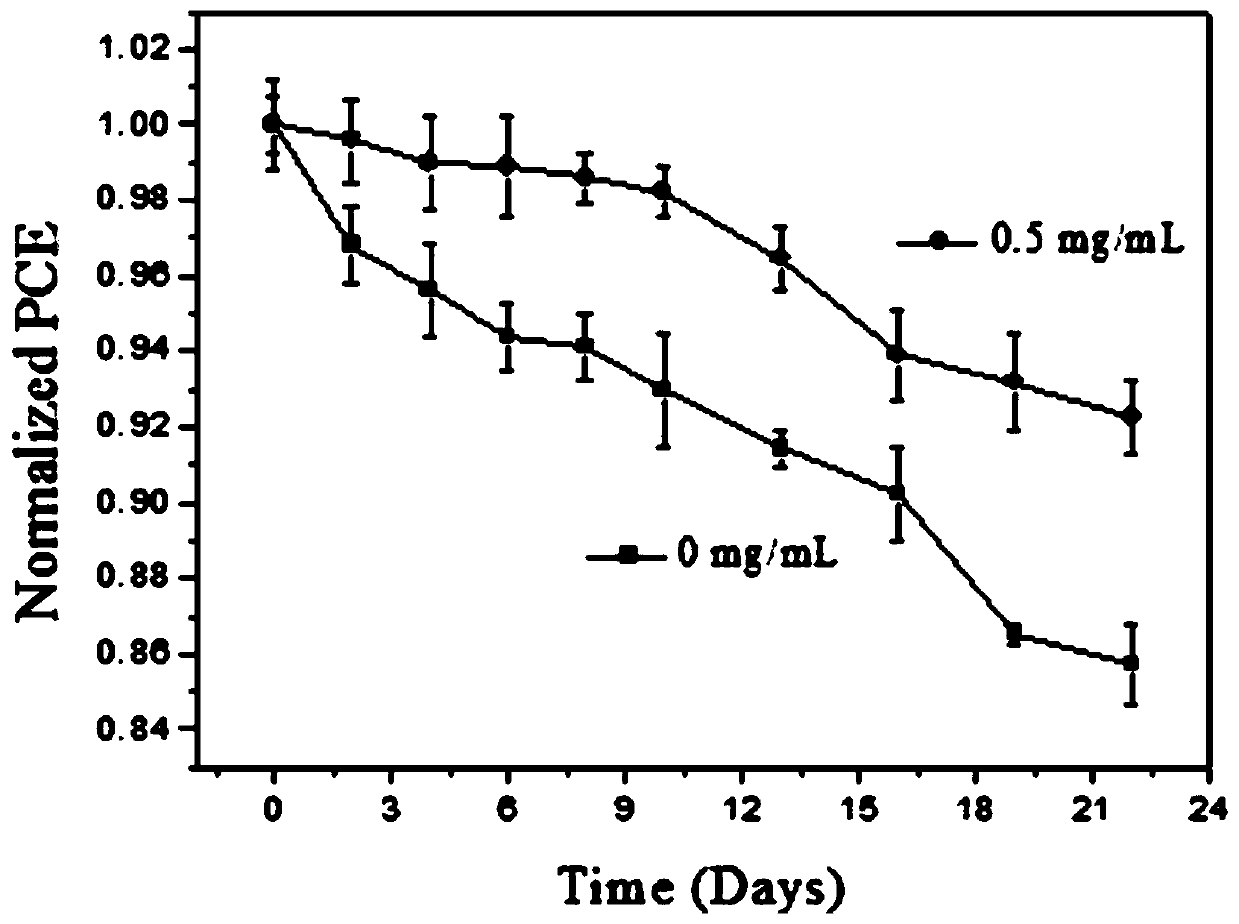

Embodiment 2

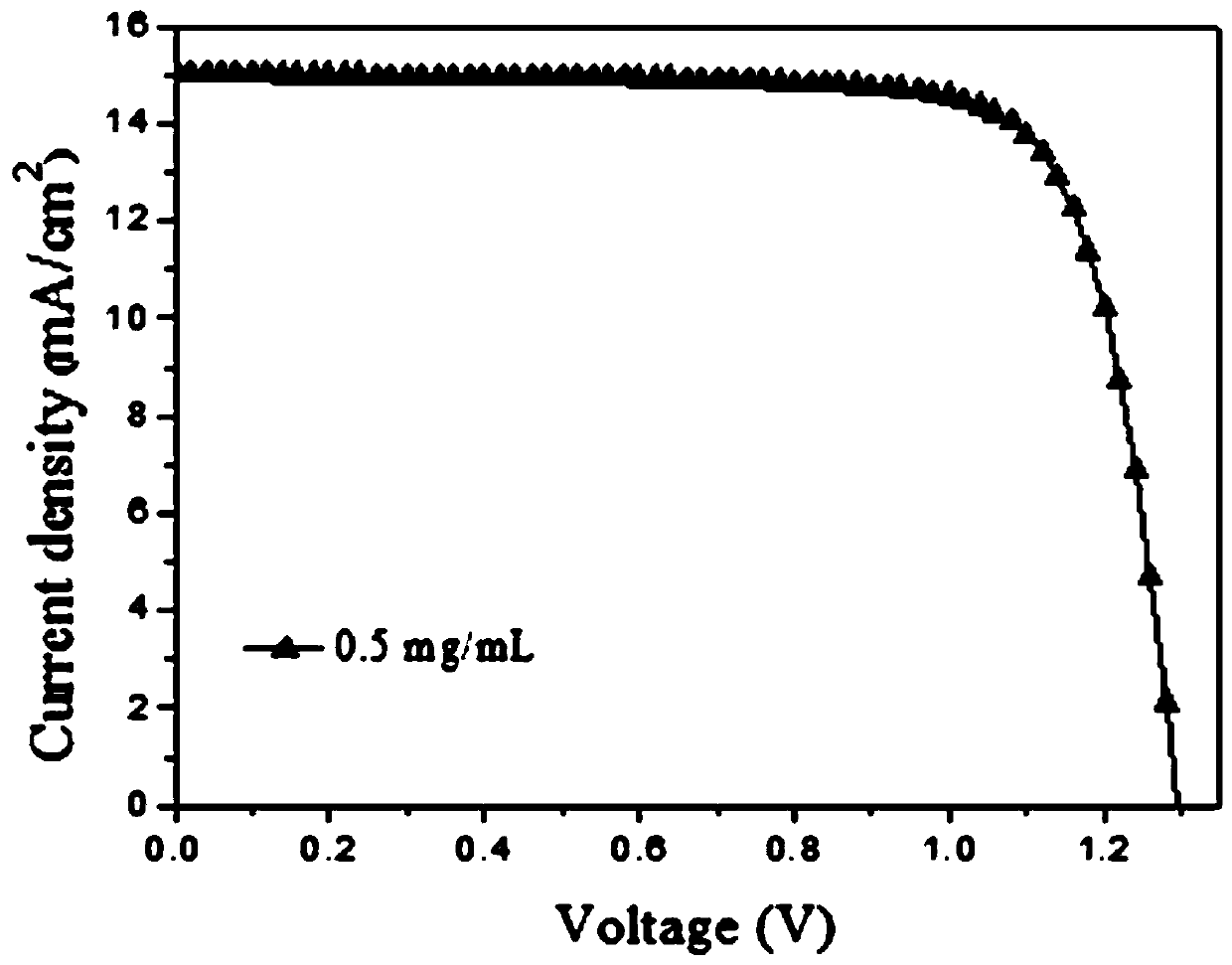

[0068] In this example, the thickness of the gold electrode is 80 nm, and the concentration of the anti-solvent dropped is 0.25 mg / mL. The other steps are the same as in Example 1. In this example, the efficiency of the inorganic perovskite solar cell is 14.38%.

Embodiment 3

[0070] In this example, the thickness of the gold electrode is 90 nm, the concentration of the anti-solvent dropped is 1 mg / mL, and the other steps are the same as in Example 1. In this example, the efficiency of the inorganic perovskite solar cell is 14.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com