Oxygen vacancy-containing layered lithium-rich cathode material and preparation method thereof

A lithium-rich cathode material and layered technology, applied in the field of layered lithium-rich cathode materials, can solve problems such as insignificant effects, and achieve the effects of simple preparation process, excellent cycle performance and stable chemical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

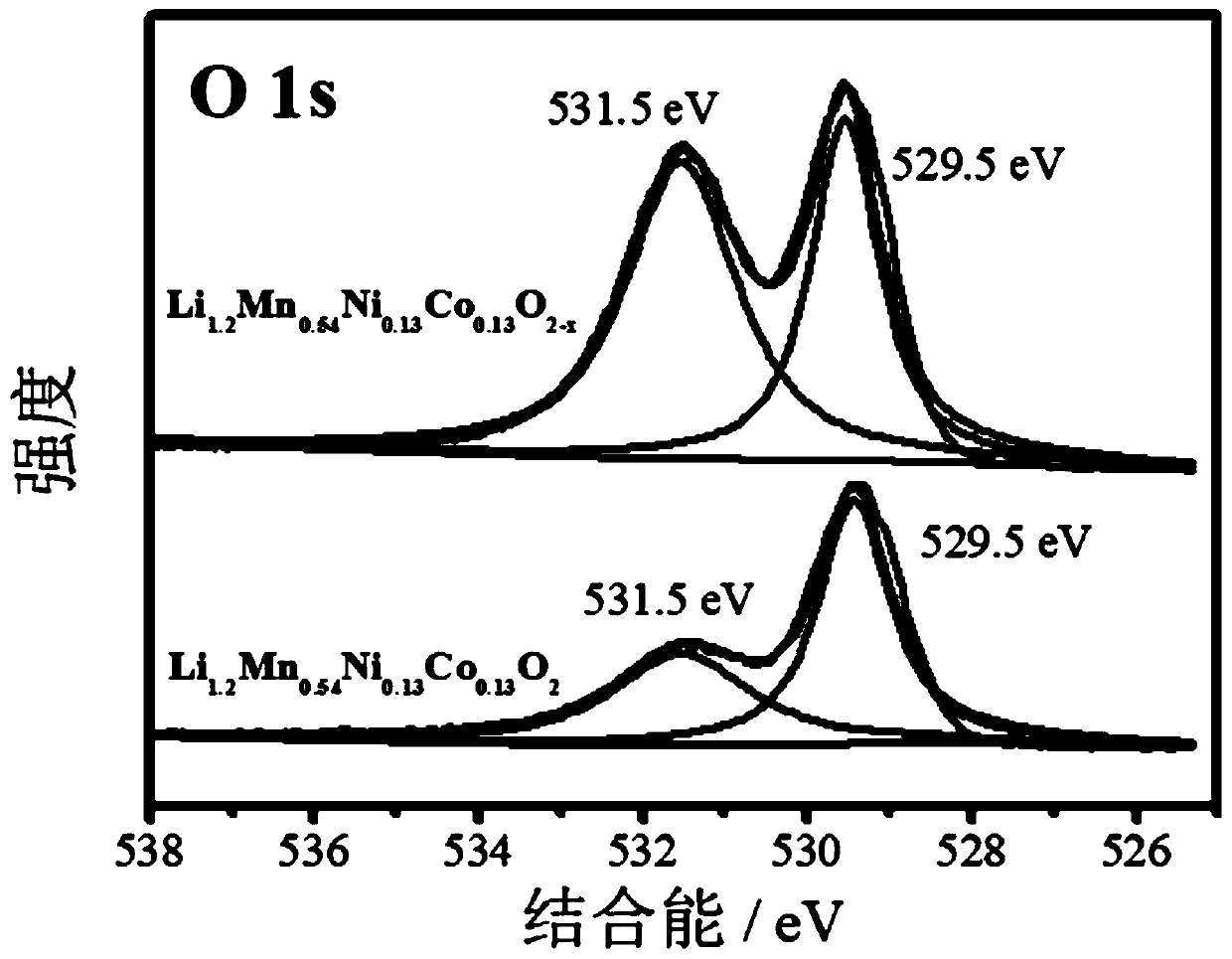

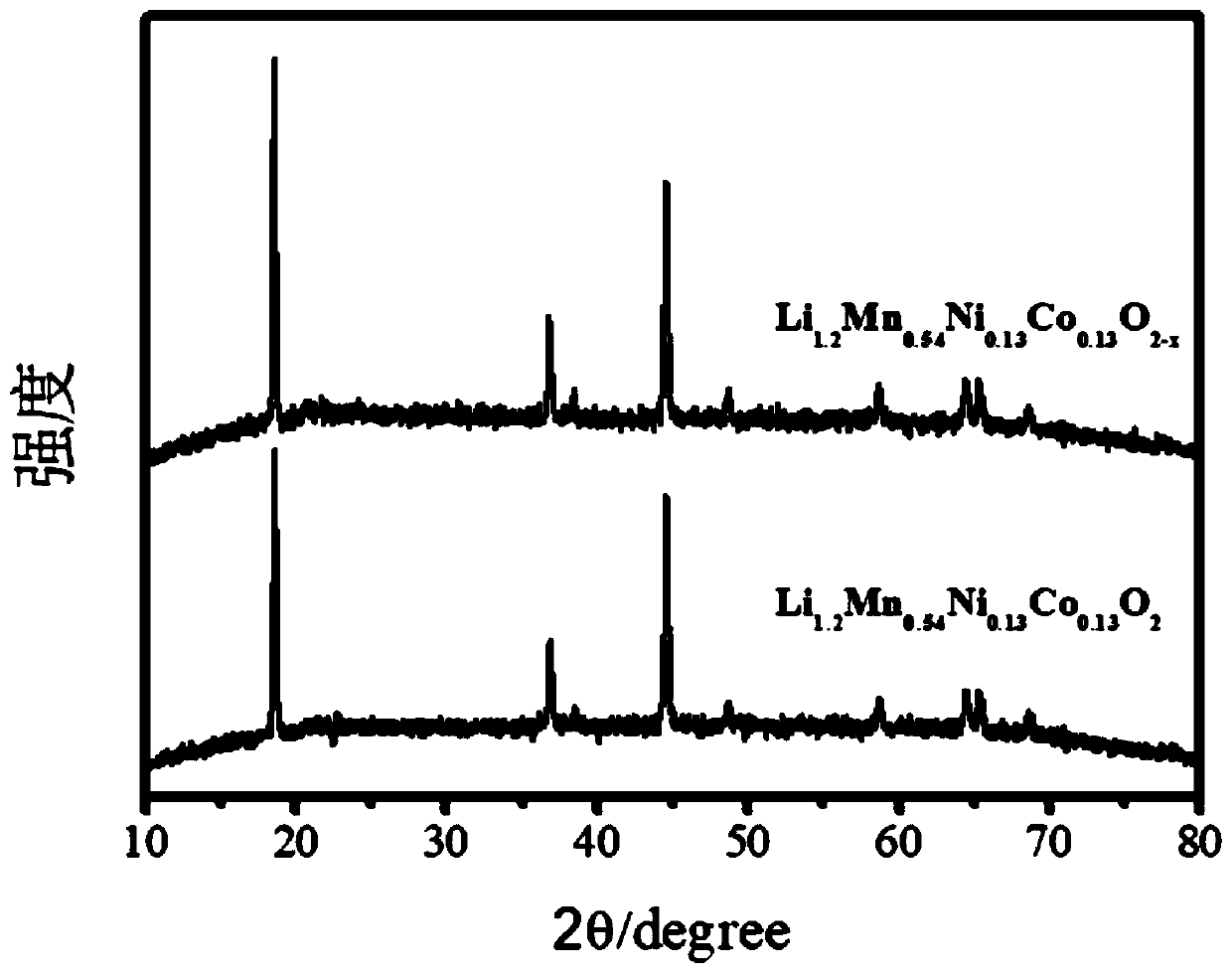

[0036] A layered lithium-rich cathode material containing oxygen vacancies, the lithium-rich manganese-based cathode material contains Li, Mn, Ni, Co and O elements.

[0037] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0038] 1) Dissolve 0.8112g of oxalic acid dihydrate in 60mL of a mixed solvent of ethanol and water (the volume ratio of ethanol and water is 1:0.2), stir and dissolve in a constant temperature water bath at 60°C to obtain solution A;

[0039] 2) Dissolve soluble 0.4820g lithium acetate, 0.4902g manganese acetate, 0.1244g nickel acetate and 0.1245g cobalt acetate in 60ml of mixed solvent of ethanol and water (the volume ratio of ethanol and water is 1:0.2), and keep the temperature at 60°C Stir in a water bath to obtain solution B;

[0040] 3) Pour the obtained solution B into solution A, stir vigorously in a constant temperature water bath at 60°C at a speed...

Embodiment 2

[0046] A layered lithium-rich cathode material containing oxygen vacancies, the lithium-rich manganese-based cathode material contains Li, Mn, Ni, Co and O elements.

[0047] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0048] 1) Dissolve 0.8112g of oxalic acid dihydrate in 60mL of a mixed solvent of ethanol and water (the volume ratio of ethanol and water is 1:0.5), stir and dissolve in a constant temperature water bath at 60°C to obtain solution A;

[0049] 2) Dissolve soluble 0.4820g lithium acetate, 0.4902g manganese acetate, 0.1244g nickel acetate and 0.1245g cobalt acetate in a mixed solvent of 60ml ethanol and water (the volume ratio of ethanol and water is 1:0.5), and keep the temperature at 60°C Stir in a water bath to obtain solution B;

[0050] 3) Pour the obtained solution B into solution A, and dry at 400rpm in a constant temperature water bath at 70°C, and dry ...

Embodiment 3

[0053] A layered lithium-rich cathode material containing oxygen vacancies, the lithium-rich manganese-based cathode material contains Li, Mn, Ni, Co and O elements.

[0054] The preparation method of the above-mentioned lithium-rich manganese-based positive electrode material specifically includes the following steps:

[0055] 1) Dissolve 0.8112g of oxalic acid dihydrate in 60mL of a mixed solvent of ethanol and water (the volume ratio of ethanol and water is 1:0.6), stir and dissolve in a constant temperature water bath at 60°C to obtain solution A;

[0056] 2) Dissolve soluble 0.4820g lithium acetate, 0.4902g manganese acetate, 0.1244g nickel acetate and 0.1245g cobalt acetate in a mixed solvent of 60ml ethanol and water (the volume ratio of ethanol and water is 1:0.6), and keep the temperature at 60°C Stir in a water bath to obtain solution B;

[0057] 3) Pour the obtained solution B into solution A, dry it in a constant temperature water bath at 60°C at a speed of 500rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com