Method for determining a beam profile of a laser beam, and processing machine

A beam profile and processing machine technology, used in additive processing, manufacturing, photometry, etc., can solve the problems of large installation space of measuring instruments, high time consumption, and inability to perform beam profile determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

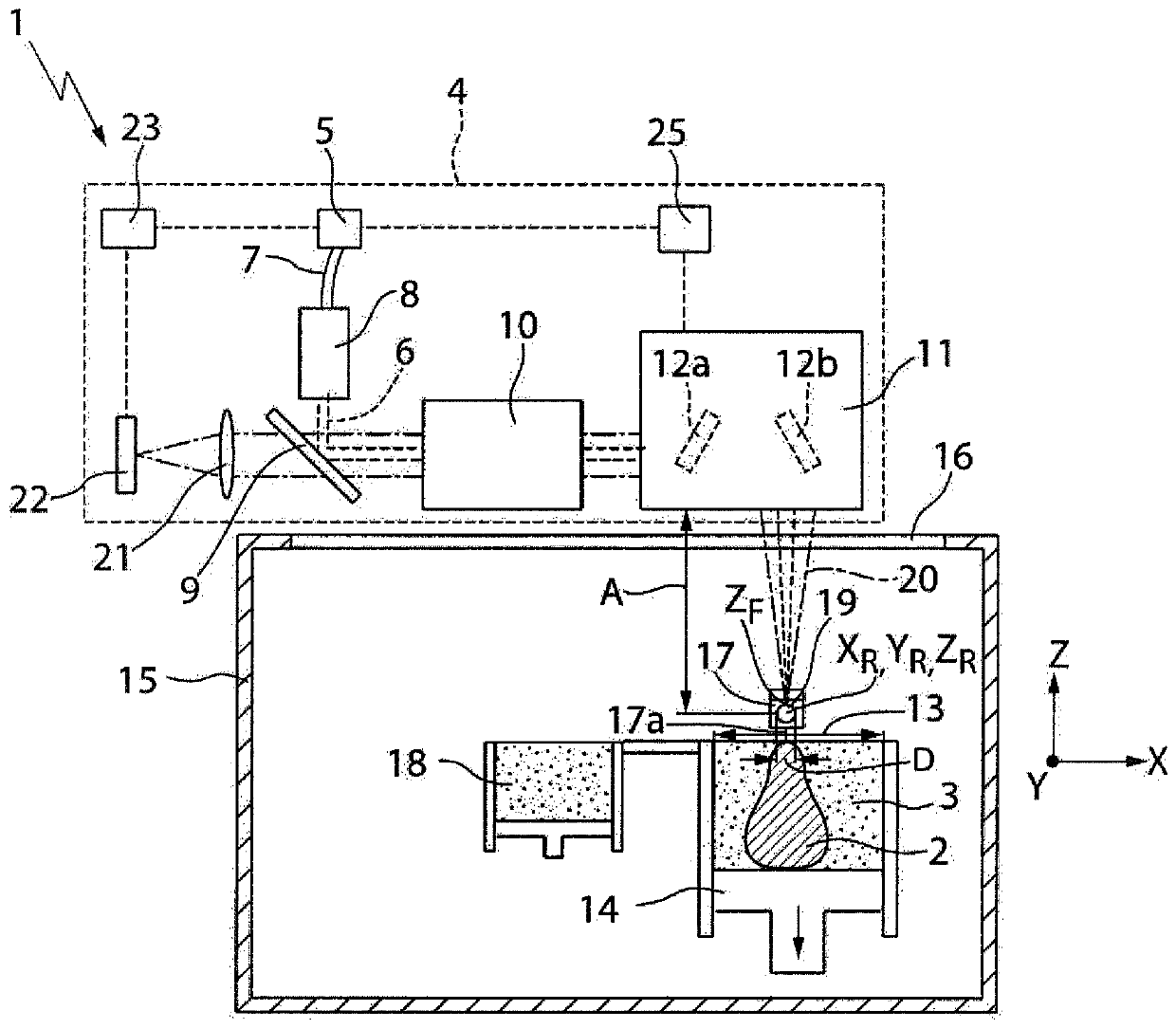

[0040] figure 1 An exemplary structure of a processing machine 1 for producing a three-dimensional component 2 by irradiating a powder layer 3 in figure 1In the example shown, they are arranged one above the other and form a powder bed in which the three-dimensional component 2 is embedded. The processing machine 1 has an irradiation device 4 with a laser source 5 in the form of a fiber laser for generating a laser beam 6 which is guided via an optical cable 7 and a collimation device 8 to a deflecting mirror 9 superior. In the example shown, the laser beam 6 is a high-power processing laser beam which is used to irradiate or melt the powder layer 3 locally. Alternatively, the laser beam 6 can be a pilot laser beam which is also generated by the laser source 5 in the form of a fiber laser. In the example shown, the processing laser beam 6 has a different wavelength than the pilot laser beam. exist figure 1 In the example 1 shown, the deflection mirror 9 has a dielectric c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com