A preparation method of tobacco endogenous Maillard reaction spice and its application in novel tobacco products

An endogenous and reactive technology, applied in the fields of application, tobacco, and tobacco treatment, to achieve high production efficiency, reduce dryness and irritation, and improve the effect of tobacco imitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

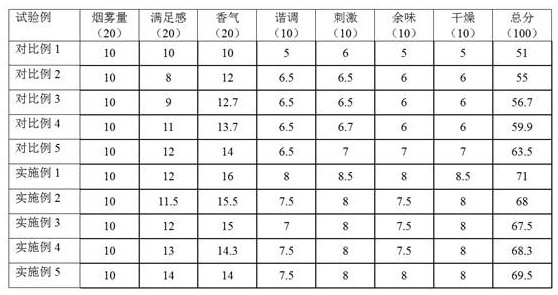

Examples

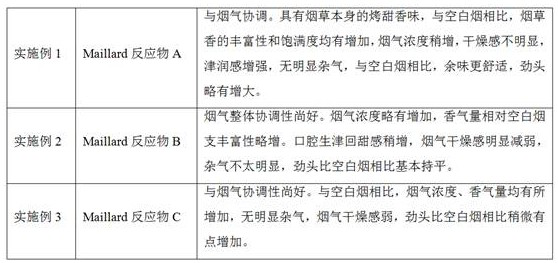

Embodiment 1

[0044] (1) The burley tobacco leaves and flue-cured tobacco leaves before threshing and re-roasting were rehydrated, destemmed and shredded respectively, then dried in an electric blast drying oven at a temperature of 40 ℃ for 40 min, and sealed for later use. Weigh 100 g (accurate to 0.01 g) of pretreated shredded Burley tobacco and 100 g (accurate to 0.01 g) of pretreated flue-cured tobacco into a high-pressure PE bag, add 600 mL of distilled water, and perform ultra- High-pressure treatment, the pressure was raised to 300 MPa and maintained for 20 minutes, and the pressure relief time was 10 s. The treated liquid of Burley tobacco and flue-cured tobacco after ultra-high pressure treatment was subjected to vacuum filtration, and the obtained filtrate was the ultra-high pressure extract of tobacco leaves.

[0045] (2) Propylene glycol and sorghum liquor base were prepared at a ratio of 2:1 by volume, and stirred evenly. As the Maillard reaction solvent, 50 g of xylose, 400 mL ...

Embodiment 2

[0047] (1) After threshing and re-roasting, Burley tobacco leaves and flue-cured tobacco leaves were rehydrated, loosened, shredded, and then dried in an electric blast drying oven at a temperature of 45°C for 30 minutes, and sealed for later use. Weigh 100 g (accurate to 0.01 g) of pretreated shredded Burley tobacco and 100 g (accurate to 0.01 g) of pretreated flue-cured tobacco into a high-pressure PE bag, add 800 mL of distilled water, and carry out ultra- High-pressure treatment, the pressure was raised to 400 MPa and maintained for 15 minutes, and the pressure relief time was 10 s. The treated liquid of Burley tobacco and flue-cured tobacco after ultra-high pressure treatment was subjected to vacuum filtration, and the obtained filtrate was the ultra-high pressure extract of tobacco leaves.

[0048] (2) Propylene glycol and sorghum liquor base were prepared at a ratio of 1:1 by volume, and stirred evenly. As the solvent for the Maillard reaction, 80 g of xylose, 600 mL of ...

Embodiment 3

[0050] (1) Burley tobacco leaves before threshing and re-roasting were remoisturized, stemmed, and shredded, then dried in an electric blast drying oven at a temperature of 45 °C for 30 min, and sealed for later use. After threshing and rebaking, the flue-cured tobacco leaves were rehydrated, loosened, shredded, dried in an electric blast drying oven at a temperature of 45°C for 30 minutes, and sealed for later use. Weigh 100 g (accurate to 0.01 g) of pretreated shredded Burley tobacco and 100 g (accurate to 0.01 g) of pretreated shredded flue-cured tobacco into a high-pressure PE bag, add 1000 mL of distilled water, and perform ultra-high pressure after stirring. For treatment, the pressure was raised to 400 MPa and kept for 15 minutes, and the pressure relief time was 10 s. The treated liquid of Burley tobacco and flue-cured tobacco after ultra-high pressure treatment was subjected to vacuum filtration, and the obtained filtrate was the ultra-high pressure extract of tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com