A kind of alkali-modified composite catalyst and the method for producing ethylene by hydrogenation reaction of carbon monoxide

A catalyst and oxide technology, applied in catalyst activation/preparation, molecular sieve catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve problems such as less than 30%, low single selectivity of ethylene, affecting application and so on , to achieve the effect of inhibiting selectivity, unique type selection effect and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] One, the preparation of I component

[0034] Below by embodiment the present invention is described further, but the scope of claims of the present invention is not limited by these embodiments. At the same time, the embodiment only provides some conditions for realizing this purpose, but it does not mean that these conditions must be met to achieve this purpose.

[0035] The specific surface area of the sample can be tested by nitrogen or argon physical adsorption.

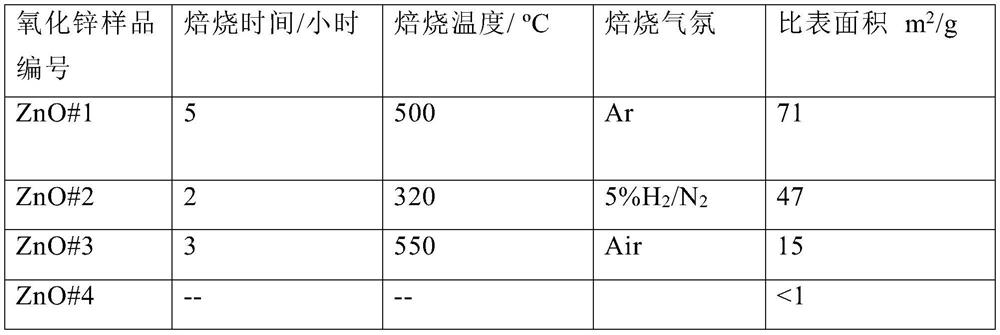

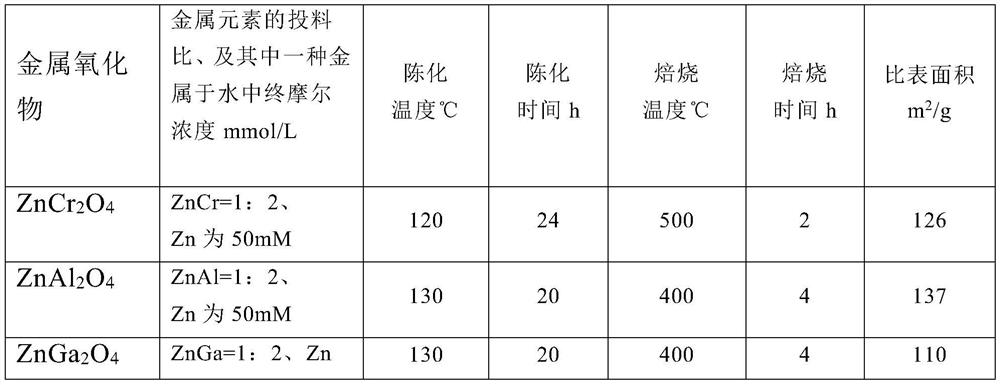

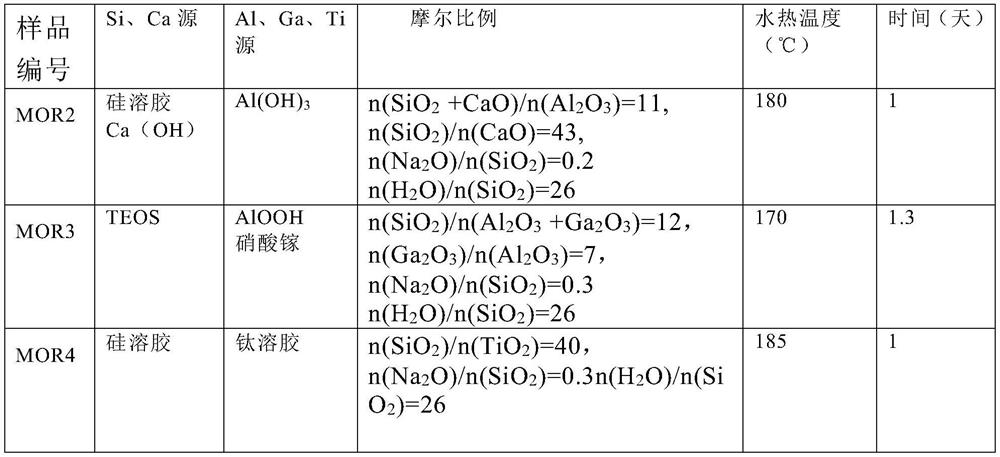

[0036] Metal oxide of the present invention can obtain by buying the metal oxide of commercially available high specific surface area, also can obtain by following several methods:

[0037] 1. Preparation of Catalyst Component I

[0038] (1) Synthesis of ZnO materials with high specific surface area by precipitation method:

[0039] (1) Weigh 3 parts, 0.446g (1.5mmol) Zn(NO 3 ) 2 ·6H 2 O in 3 containers, then weigh 0.300g (7.5mmol), 0.480g (12mmol), 0.720g (18mmol) NaOH and add them to the above 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com