Preparation method of hexahedron ZnCo2O4 composite material

A composite material and hexahedral technology, which is applied in the field of preparation of hexahedral ZnCo2O4 composite materials, can solve the problems of many bimetallic oxide impurities, limited development and high process energy consumption, and achieves the effects of simple preparation steps, low density and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a hexahedral ZnCo 2 O 4 A preparation method of a composite material, the method specifically comprises the following steps:

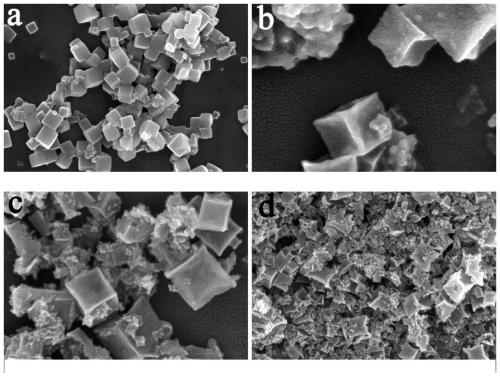

[0027] (1) Synthesis of ZnCo-ZIF composites

[0028] Weigh Zn(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and CTAB (hexadecyltrimethylammonium bromide) were dissolved to form A solution, 2-methylimidazole was weighed and dissolved to form B solution, A solution and B solution were sonicated and mixed to obtain a solid-liquid mixture, and then the solid-liquid mixture was obtained. The liquid mixture is subjected to solid-liquid separation treatment, and the solid obtained from the separation is collected and dried to obtain a solid powder;

[0029] (2) The solid powder obtained in step (1) is placed in an air atmosphere for high temperature calcination, and the hexahedral ZnCo disclosed in the present invention can be obtained 2 O 4 composite material.

[0030] In order to further realize the technical effect of the ...

Embodiment 1

[0037] A kind of hexahedral ZnCo 2 O 4 Preparation of composite materials

[0038] method, the method specifically comprises the following steps:

[0039] (1) Preparation of ZnCo-ZIF composites

[0040] Weigh 0.3g Zn(NO 3 ) 2 ·6H 2 O, 0.6g Co(NO 3 ) 2 ·6H 2 O and 15mg CTAB (hexadecyltrimethylammonium bromide) were dissolved in 50mL of deionized water to form A solution, which was stirred for 30min by ultrasonic; 2-methylimidazole was weighed and dissolved in 100mL of deionized water to form B solution, and ultrasonically stirred for 30min ; Then the A and B solutions were mixed, wherein Zn(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 The molar ratio of O and 2-methylimidazole was 1:2:100; the mixed solution was ultrasonically stirred for 10 min at room temperature, washed with deionized water for 3 times, and dried in an oven at 70 °C for 20 h to obtain bimetallic ZnCo-ZIF powder;

[0041] (2) Hexahedral ZnCo 2 O 4 Preparation of composite materials

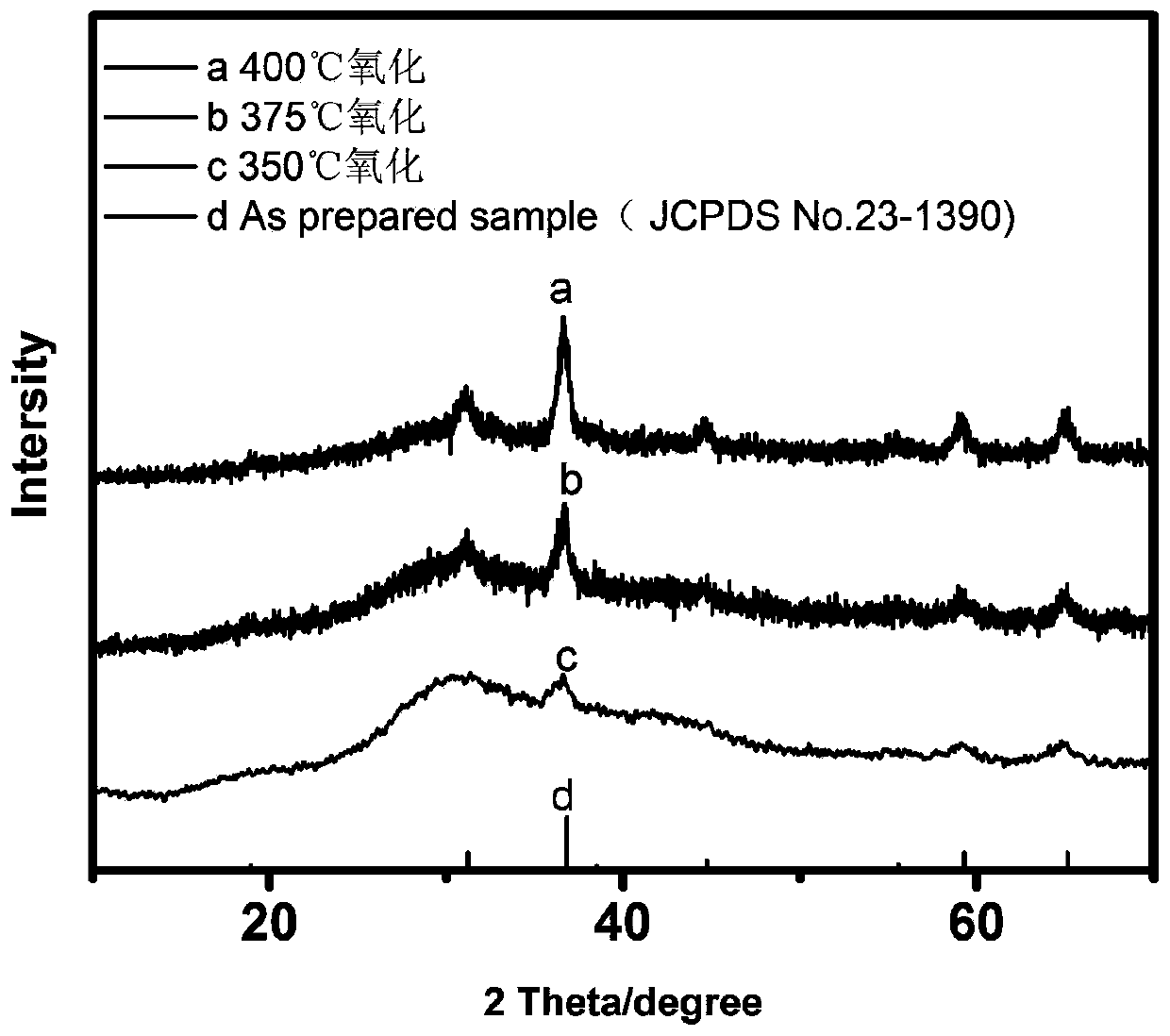

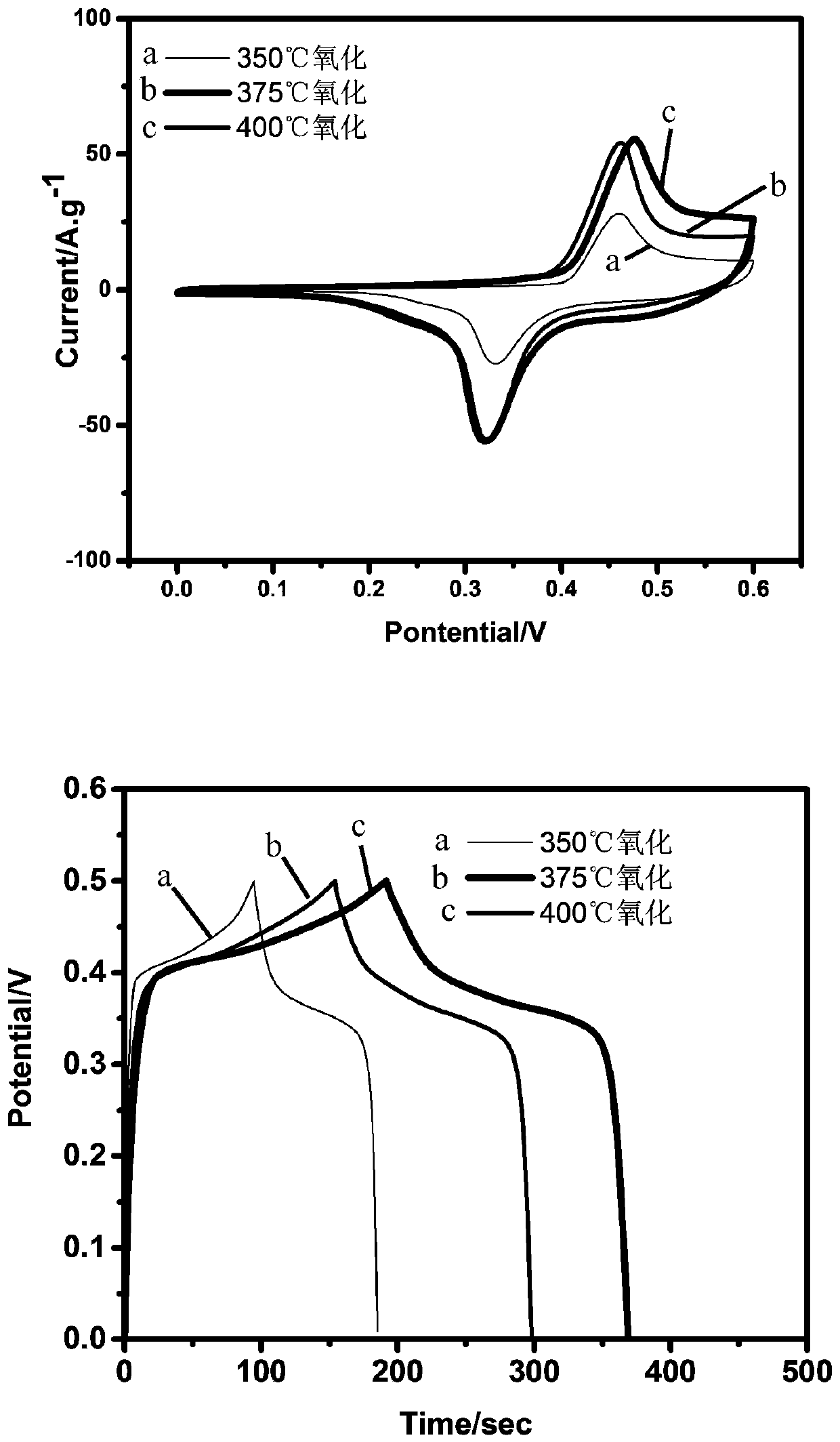

[0042] The bime...

Embodiment 2

[0044] The difference between this example and Example 1 is that: the bimetallic ZnCo-ZIF powder obtained in step (1) is placed in a tube furnace at 375 ° C for oxidative calcination for 4 hours, and other parameters remain unchanged, according to Example 1 The disclosed preparation method prepares a ZnCo-ZIF composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com