A kind of purification process of n,o-1,3-diacetylindole

A technology of diacetyl indole and diacetyl indole, which is applied in the field of purification technology of N,O-1,3-diacetyl indole, can solve the problems of long time consumption, inconsistency, low effect and the like

Active Publication Date: 2022-05-31

CHANGZHOU VOCATIONAL INST OF ENG

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1) The purity of the obtained product is about 80%, and the distribution coefficient difference between the product, by-products and raw materials in water or common organic solvents is relatively small. Using common crystallization method, the purity is not more than 90%. Crystallization efficiency is low and time-consuming

[0004] 2) Another method for purifying N,O-1,3-diacetylindole is to use silica gel for column chromatography. If a large amount of purification is performed, the amount of silica gel used will be large and will cause large waste solid pollution. It does not meet the requirements of the current green chemical industry; using a large amount of solvents at the same time will cause a large amount of waste liquid discharge or high waste liquid treatment costs; the operation of column chromatography is difficult, and senior operators are required, and the personnel cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

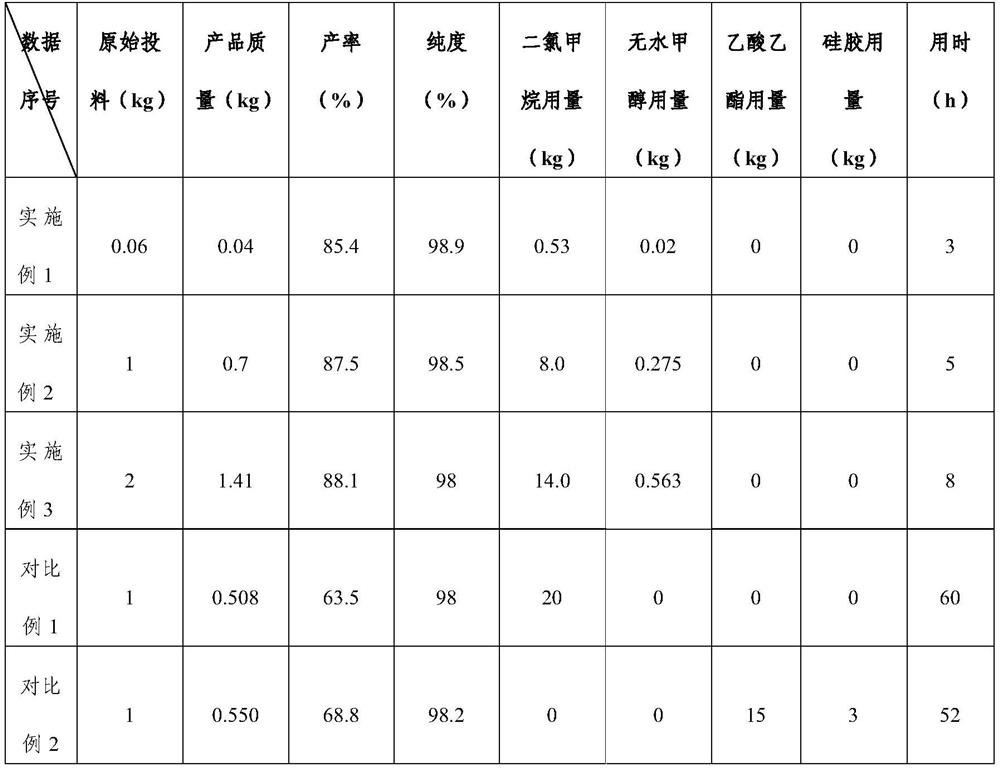

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a purification process of N,O-1,3-diacetylindole, which includes four processes of pretreatment, configuration of beating liquid, beating and impurity removal and post-treatment, with simple operation steps and strong practicability. The traditional recrystallization method is replaced by the mixed liquor beating method, which not only improves the purification efficiency of N,O-1,3-diacetylindole, but also avoids the defects of long time-consuming and many types of solvents used in traditional repeated recrystallization, and at the same time It avoids the generation of a large amount of silica gel waste residue when using silica gel column chromatography for purification, which meets the requirements of green and environmental protection chemistry; the solvent polarity of the beating liquid in this process is 6-6.2, so that N,O-1,3-diacetylindole can be compared It is simply separated from other substances to obtain a product with high purity, which ensures the quality of the product.

Description

A kind of purification technology of N,O-1,3-diacetyl indole technical field The present invention relates to chemical synthesis technical field, be specifically related to a kind of purification process of N,O-1,3-diacetyl indole art. Background technique N,O-1,3-diacetyl indole is a kind of crude drug, also can be used for synthesizing other medicines as medicine intermediate thing. At present, the commonly used synthetic method of N,O-1,3-diacetyl indole is to carry out substitution reaction between o-chlorobenzoic acid and glycine, It is then neutralized with acetic anhydride, and finally obtained by a ring-forming reaction in acetic anhydride. However, this synthesis method currently exists In the following questions: 1) about 80% of the obtained product purity, product, by-product and raw material in water or common organic solvent The difference of the distribution coefficient is small. The ordinary crystallization method is used, the purity is not more ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D209/36

Inventor 蒋若愚龚玲刘长春程进

Owner CHANGZHOU VOCATIONAL INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com