Method of preparing chiral amine by catalytic hydrogenation of N- ulfimide by asymmetrical nickel

A technology of sulfonimide and chiral amine, which is applied in the field of asymmetric nickel-catalyzed hydrogenation of N-sulfonimide to prepare chiral amine, can solve the problems of heavy metal residues, limited application, high price, etc., and achieves mild conditions and easy operation. The effect of simplicity and good reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 2a(R 1 = Ph, R 2 =CH 3 , R 2 = Preparation of t-Bu)

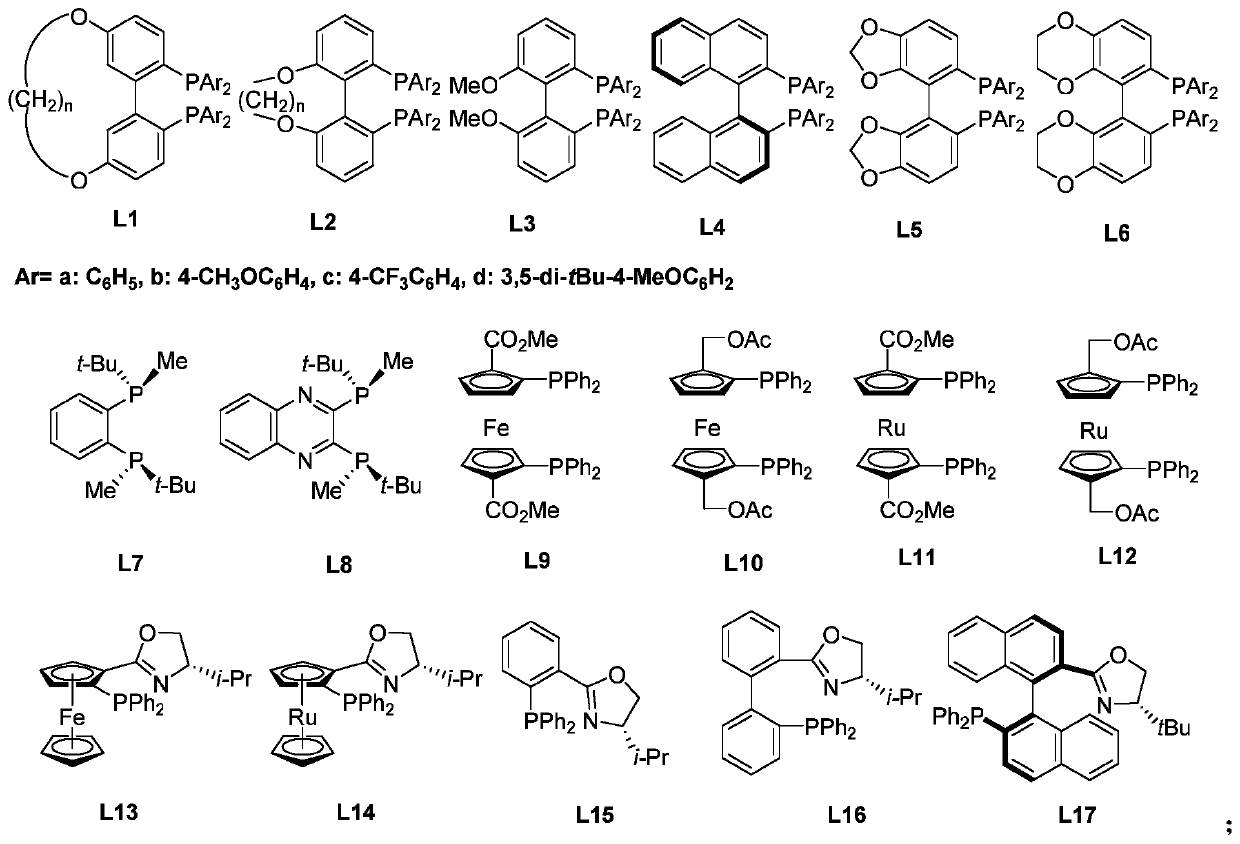

[0051] In a 10mL Schlenck tube, add phosphine ligand L1a (0.002mmol), nickel acetate tetrahydrate (0.5mg, 0.002mmol) and N-sulfonimide 1a (0.4mmol), the system was passed through the vacuum line and replaced with nitrogen for 3 Once, 1 mL of trifluoroethanol solvent was added and put into an autoclave. After 6 hydrogen replacements, the initial hydrogen pressure was 10 bar, and the reaction was stirred at 50°C for 24 hours. Cool, release gas carefully, open the autoclave, take out the vial, drain the solvent, detect the conversion by NMR, and obtain the product by column chromatography. Yield 87%, enantiomeric excess 95%. 2a: white solid, 1 H NMR (400MHz, Chloroform-d) δ7.39-7.24(m, 5H), 4.67(dq, J=8.4, 6.8Hz, 1H), 4.55(s, 1H), 1.57(d, J=6.8Hz, 3H), 1.31(s, 9H); 13 C NMR (101MHz, Chloroform-d) δ143.8, 129.0, 127.7, 126.1, 60.0, 54.7, 25.9, 24.4.

Embodiment 2

[0053] 2a(R 1 = Ph, R 2 =CH 3 , R 3 = Preparation of t-Bu)

[0054] In a 10mL Schlenck tube, add phosphine ligand L1b (0.002mmol), nickel acetate tetrahydrate (0.5mg, 0.002mmol) and N-sulfonimide 1a (0.4mmol), the system was passed through the vacuum line and replaced with nitrogen for 3 Once, 1 mL of trifluoroethanol solvent was added and put into an autoclave. After 6 times of hydrogen replacement, the initial hydrogen pressure was 10 bar, and the reaction was stirred at 50°C for 24 hours. Cool, release gas carefully, open the autoclave, take out the vial, drain the solvent, detect the conversion by NMR, and obtain the product by column chromatography. Yield 92%, enantiomeric excess 94%. 2a: white solid, 1 H NMR (400MHz, Chloroform-d) δ7.39-7.24(m, 5H), 4.67(dq, J=8.4, 6.8Hz, 1H), 4.55(s, 1H), 1.57(d, J=6.8Hz, 3H), 1.31(s, 9H); 13 C NMR (101MHz, Chloroform-d) δ143.8, 129.0, 127.7, 126.1, 60.0, 54.7, 25.9, 24.4.

Embodiment 3

[0056] 2a(R 1 = Ph, R 2 =CH 3 , R 3 = Preparation of t-Bu)

[0057] In a 10mL Schlenck tube, add phosphine ligand L1c (0.002mmol), nickel acetate tetrahydrate (0.5mg, 0.002mmol) and N-sulfonimide 1a (0.4mmol), the system was passed through the vacuum line and replaced with nitrogen for 3 Once, 1 mL of trifluoroethanol solvent was added, put into an autoclave, and after 6 hydrogen replacements, the initial hydrogen pressure was 10 bar, and the reaction was stirred at 50° C. for 24 hours. Cool, release gas carefully, open the autoclave, take out the vial, drain the solvent, detect the conversion by NMR, and obtain the product by column chromatography. Yield 95%, enantiomeric excess 95%. 2a: white solid, 1 H NMR (400MHz, Chloroform-d) δ7.39-7.24(m, 5H), 4.67(dq, J=8.4, 6.8Hz, 1H), 4.55(s, 1H), 1.57(d, J=6.8Hz, 3H), 1.31(s, 9H); 13 C NMR (101MHz, Chloroform-d) δ143.8, 129.0, 127.7, 126.1, 60.0, 54.7, 25.9, 24.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com