A kind of hot-melt adhesive film for UV curing type flexible flat cable and preparation method thereof

A hot-melt adhesive film, flexible and flat technology, applied in the field of circuit board processing, can solve the problems of conductor offset, slow pressing speed, hot-melt adhesive film overflow, etc., to achieve excellent anti-overflow adhesive performance, reduced fluidity, and storage long term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

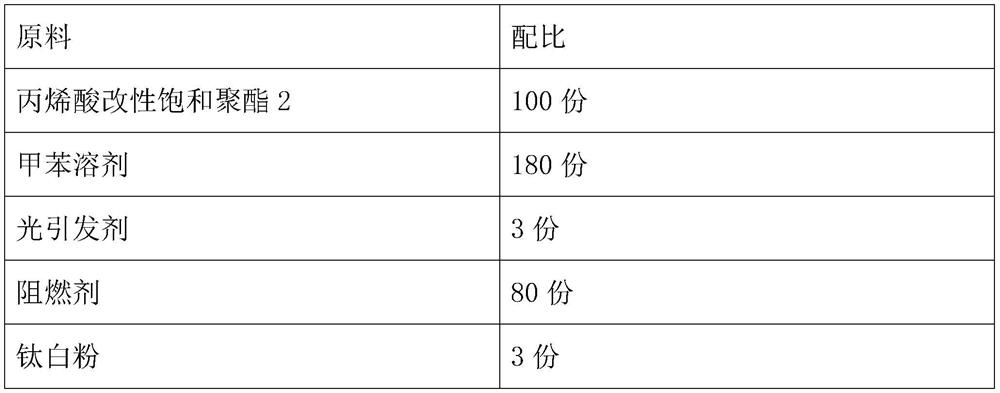

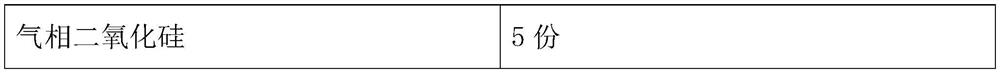

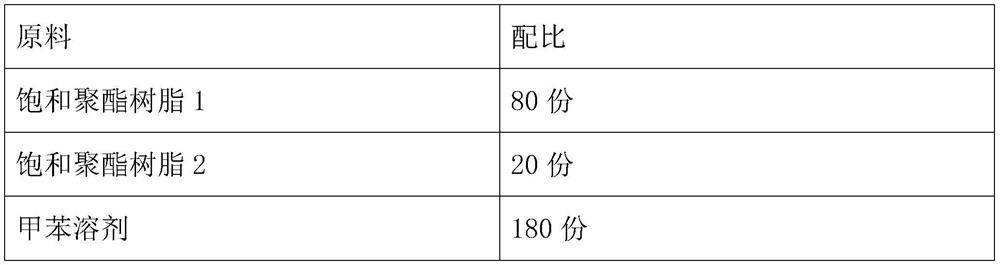

[0042] The preparation method of the above-mentioned UV curing type flexible flat cable with hot-melt adhesive film, comprises the following steps:

[0043] Step 1: Resin is dissolved; add 80-120 parts of acrylic modified saturated polyester and 100-180 parts of toluene into the reaction kettle, heat up to 60-80°C, stir, and control the stirring speed at 500-1000r / min to disperse and dissolve;

[0044] Step 2: Paint dispersion and grinding; add 60-100 parts of flame retardant, 1-3 parts of titanium dioxide, 0.5-5 parts of fumed silica into the resin dispersion, add 60-100 parts of toluene solvent, 1000-2000r / min Stir and disperse evenly, and grind until the fineness is less than 10um;

[0045] Step 3: Stir further; add 0.5-5 parts of photoinitiator, continue stirring at 500-1000r / min to disperse evenly;

[0046] Step 4: coating; the hot melt adhesive film obtained above is evenly coated on the PET base film or PI film, and dried at 70-160°C, and the production process is prot...

Embodiment 1

[0049] raw material Proportion Acrylic Modified Saturated Polyester 1 100 copies Toluene solvent 180 servings photoinitiator 3 copies flame retardant 80 servings Titanium dioxide 3 copies Fumed silica 5 servings

Embodiment 2

[0051] raw material Proportion Acrylic Modified Saturated Polyester 1 100 copies Toluene solvent 180 servings photoinitiator 0.5 servings flame retardant 80 servings Titanium dioxide 3 copies Fumed silica 5 servings

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com