Phosphorus source supply system suitable for tubular diffusion process

A diffusion process and supply system technology, applied in the field of phosphorus source supply system, can solve the problems of increasing the workload of loading and unloading source bottles, increasing the consumption of phosphorus oxychloride, and inconvenient handling of phosphorus oxychloride, so as to reduce the complexity of the overall system , Improve the diffusion quality, improve the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

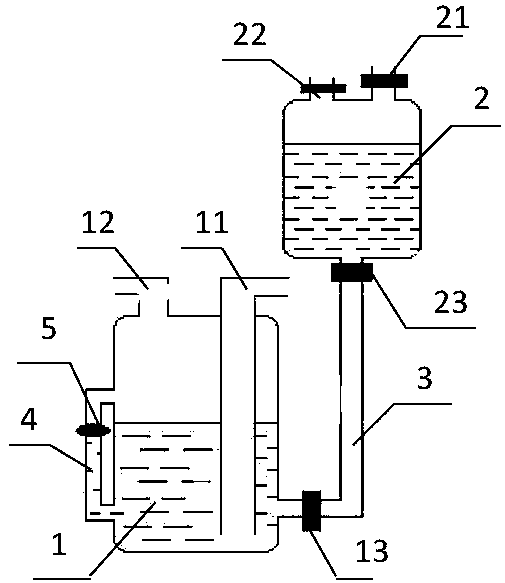

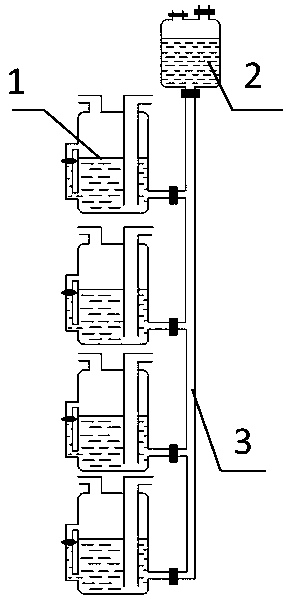

[0026] Example 1, as figure 1 As shown, a phosphorus source supply system suitable for use in a tubular diffusion process includes a main source bottle 1 in which a liquid source, such as phosphorus oxychloride, is stored. The air inlet pipe 11 includes an extension portion, the extension portion has a longer length and is submerged below the liquid surface, and is used for inputting an inert gas, such as nitrogen gas. In this technical solution, a detection pipeline 4 connected to the main source bottle 1 is provided on one side, and the liquid source also enters the detection pipeline 4, wherein a liquid level sensor 5 is provided, and the liquid level sensor 5 can be used For mature products on the market, the specific brands and models are not specifically limited here. When the liquid level sensor 5 senses that the liquid level height value in the detection pipeline 4 and the main source bottle 1 is lower than the preset threshold, it will transmit a signal to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com