Method for preparing lithium-rich composite cathode material, cathode and battery

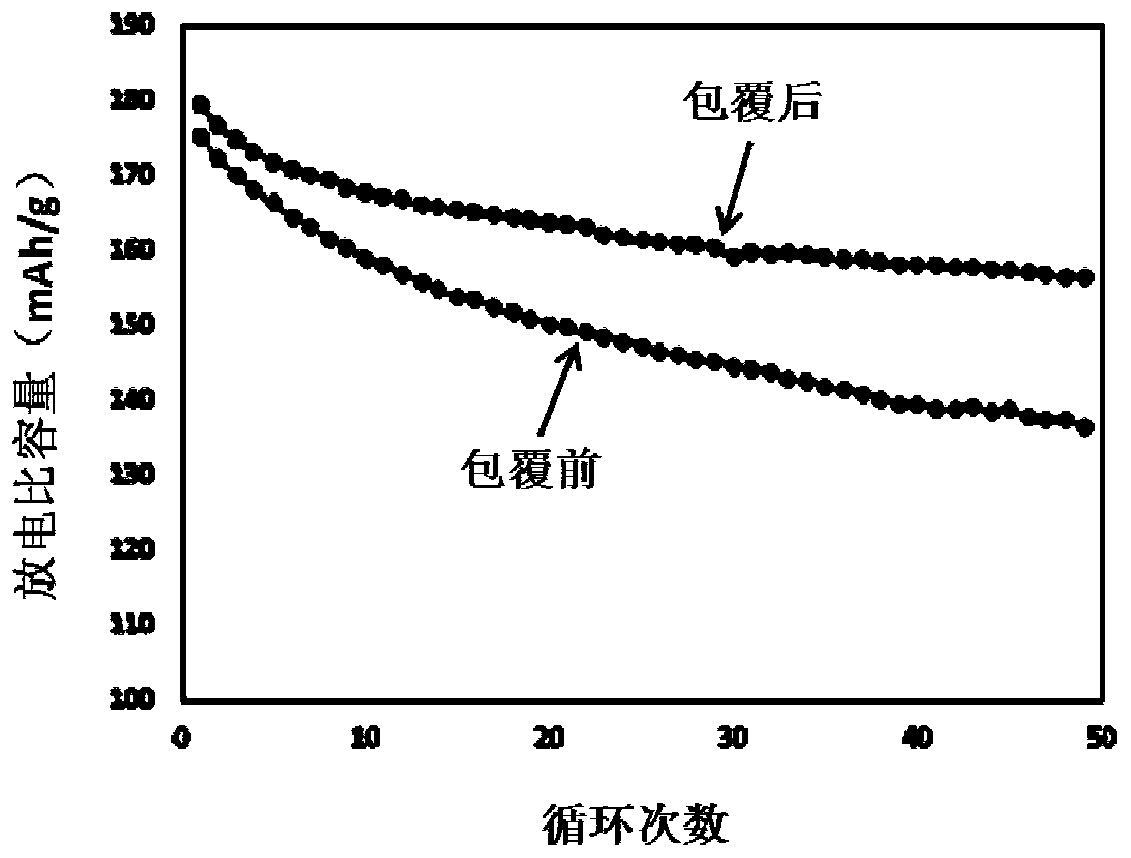

A technology of composite positive electrode materials and lithium-rich materials, which is applied in the field of preparation of lithium-rich composite positive electrode materials, can solve the problems that hinder the large-scale application of lithium-rich materials, poor rate performance and cycle performance, and voltage attenuation, so as to reduce damage and improve performance drop, good rate performance and cycle performance, and the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

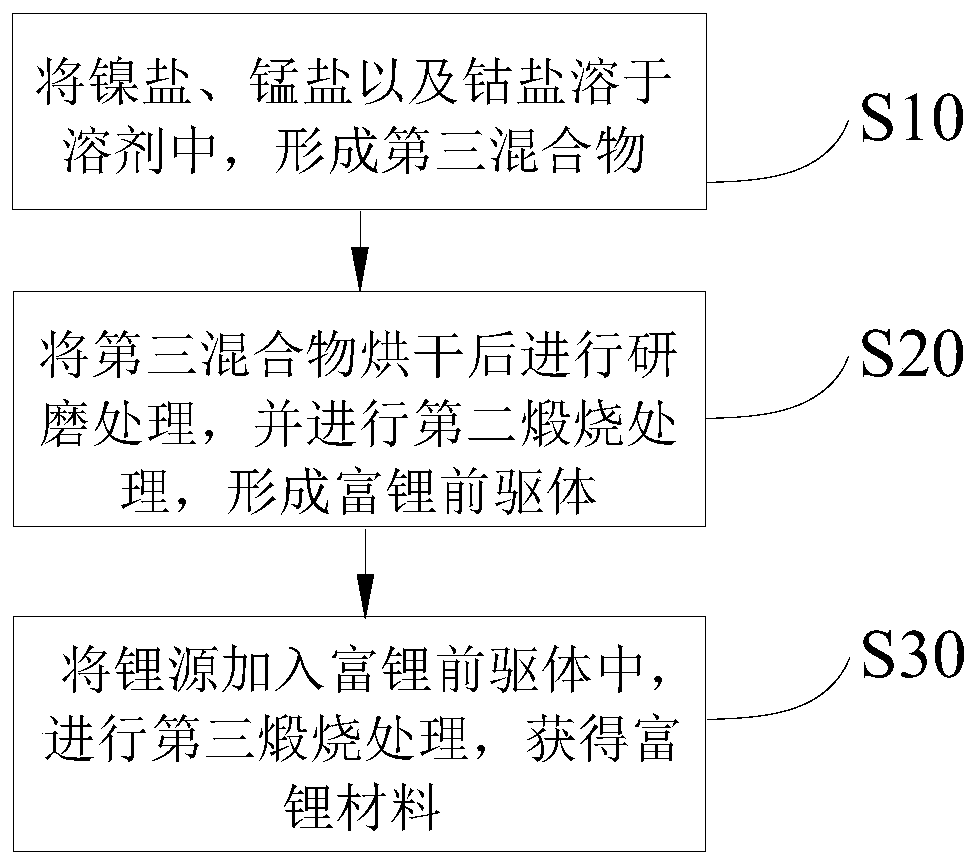

[0042] Embodiment 1, preparation lithium-rich material

[0043] (1) dissolving nickel salt, manganese salt and cobalt salt in a solvent in a ratio of 1:6:1 to form a mixture;

[0044] (2) Grinding the mixture after drying, and performing high-temperature sintering treatment to form a lithium-rich precursor;

[0045] (3) adding a lithium source into the lithium-rich precursor, and performing a calcination treatment to obtain a lithium-rich material.

Embodiment 2

[0046] Example 2, preparation of lithium-rich materials coated with lithium trifluoromethanesulfonate on the surface

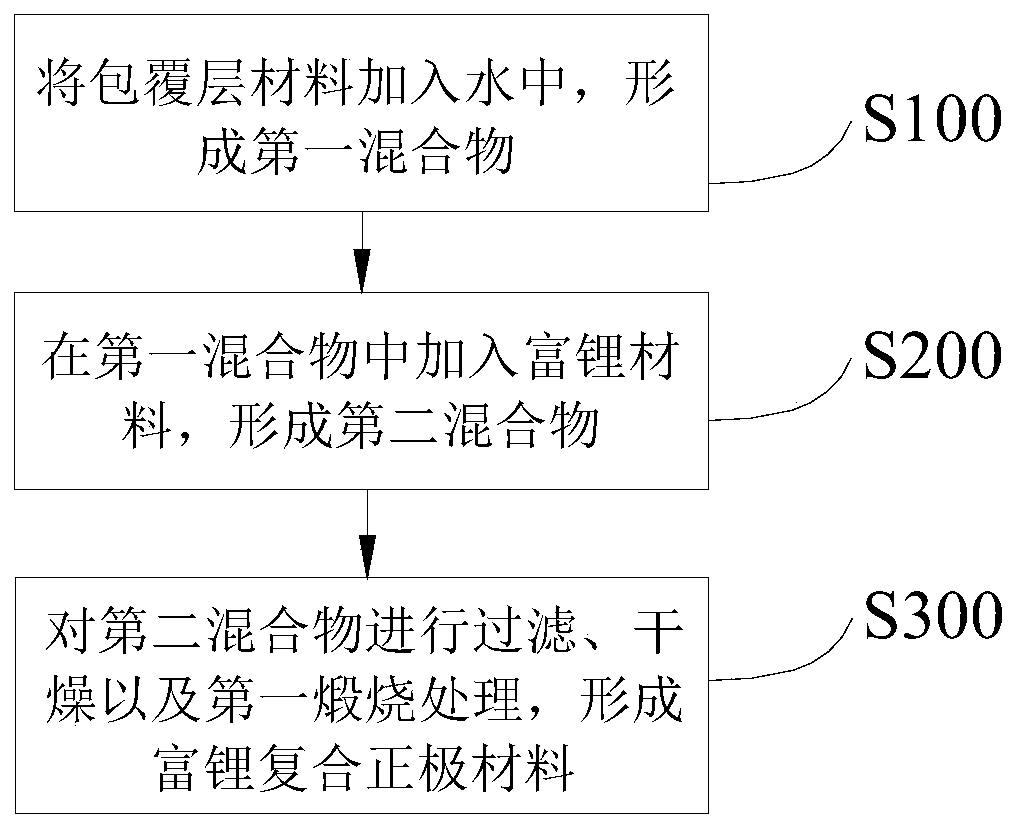

[0047] (1) Lithium trifluoromethanesulfonate is added to deionized water, and stirred evenly to form the first mixture;

[0048] (2) Add the lithium-rich material prepared in Example 1 to the first mixture, the addition ratio of the lithium-rich material and lithium trifluoromethanesulfonate is 100:3, stir and react to form a second mixture;

[0049] (3) Filtrating, drying and calcining the second mixture to obtain a lithium-rich material whose surface is coated with lithium trifluoromethanesulfonate, and obtain a lithium-rich composite positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com