A kind of steric buffer, silicon oxide composite material doped with lithium and its preparation method, lithium ion battery

A composite material, silicon oxide technology, used in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of cycle performance decline, interface instability, interface deterioration, etc., to improve the charge and discharge efficiency, and alleviate the carbon layer. Destructive, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

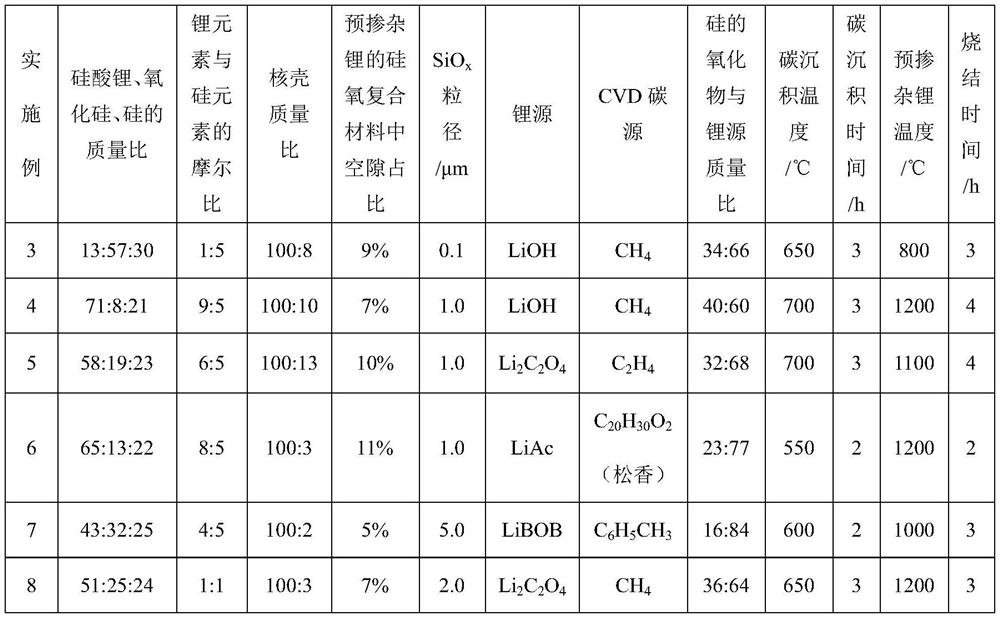

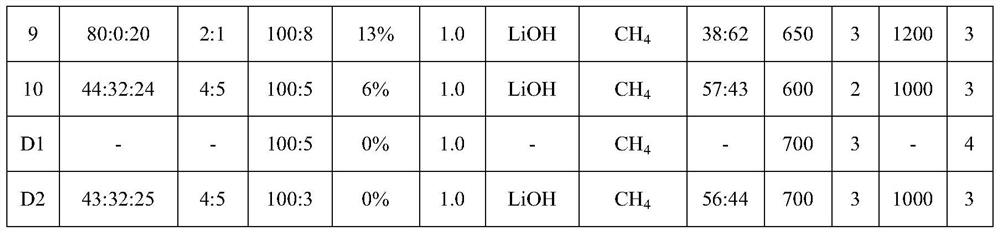

Examples

Embodiment 1

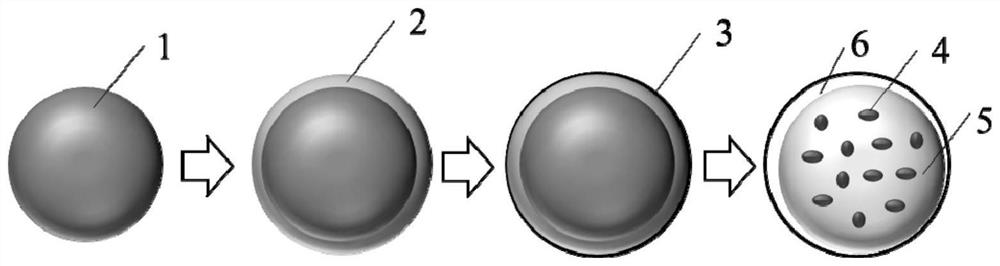

[0046] The space-buffering and lithium-doped silicon oxide composite material in this embodiment has a core-shell structure, the core is a silicon-oxygen composite material pre-doped with lithium, and the shell is a coated carbon layer; there is a space buffer structure between the core-shell. The main component of the silicon-oxygen composite material pre-doped with lithium is a mixture of lithium silicate, silicon oxide and silicon. Through further characterization and analysis, the mass ratio of lithium silicate, silicon oxide and silicon is 6:57:28; the volume of voids in the silicon-oxygen composite material pre-doped with lithium accounts for about 3%, and the molar ratio of lithium to silicon The ratio is 1:10. The mass ratio of the coated carbon layer to the silicon-oxygen composite material pre-doped with lithium is 6:100.

[0047] The preparation method of the space buffering and lithium-doped silicon oxide composite material of this embodiment comprises the followi...

Embodiment 2

[0056] The space-buffering and lithium-doped silicon oxide composite material of this embodiment has a core-shell structure, the core is a silicon-oxygen composite material pre-doped with lithium, and the shell is a coated carbon layer; there is a space buffer structure between the core-shell, that is, a void . The main component of the silicon-oxygen composite material pre-doped with lithium is a mixture of lithium silicate, silicon oxide and silicon. Through further characterization analysis, the mass ratio of lithium silicate, silicon oxide and silicon is 43:32:25; the void volume accounts for about 6% of the volume ratio of the silicon-oxygen composite material pre-doped with lithium, and the ratio of lithium to silicon The molar ratio is 4:5. The mass ratio of the coated carbon layer to the silicon-oxygen composite material pre-doped with lithium is 5:100.

[0057] The preparation method of the space buffering and lithium-doped silicon oxide composite material of this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com