Firm-type A-grade fireproof polystyrene board and manufacturing method thereof

A polystyrene board, a solid technology, applied in the field of thermal insulation and fireproof materials for exterior walls, can solve problems such as shedding, increased torque, labor and material costs, etc., to achieve enhanced compressive and tensile capabilities, improved thermal insulation performance, and improved safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

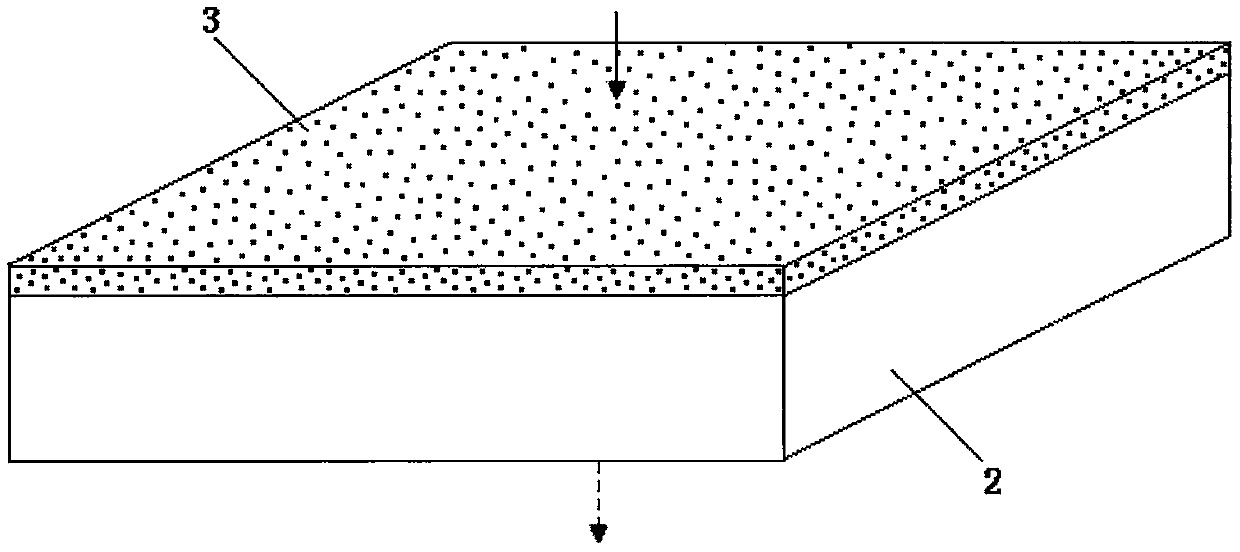

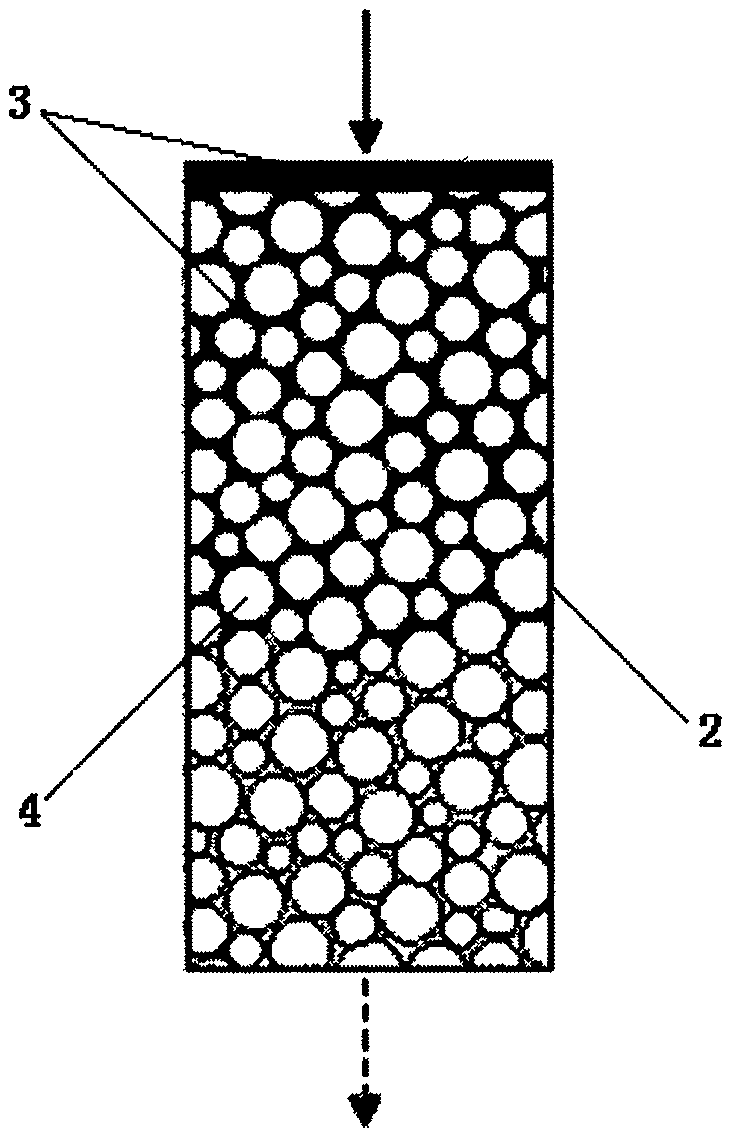

[0019] Such as Figure 1-3 As shown, the solid A-class fireproof polystyrene board 1 includes a molded foamed polystyrene board 2 and a HMW adsorbent 3 for modification, and the HMW adsorbent 3 for modification is adsorbed in the molded foamed polystyrene board 2 .

[0020] The molded foamed polystyrene board 2 is a polystyrene board for external wall insulation meeting the requirements of national standards.

[0021] The modified HMW adsorbent 3 includes cement slurry, fireproofing agent, penetrating agent, foaming agent and active agent.

[0022] combine figure 2 , 3 , the manufacture method of solid type A class fireproof polystyrene board 1, comprises the following steps:

[0023] a. Composition and ratio of HMW adsorbent 3 for modification:

[0024] The cement slurry is obtained by mixing cement above 42.5 with water;

[0025] The fire retardant includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com