Solvent and cleaning method for cleaning butyl rubber polymerization reactor

A polymerization reactor, butyl rubber technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of long cleaning time, high cleaning solvent distillation range and high energy consumption, and achieve The effect of reducing material consumption and energy consumption, good cleaning effect and long running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

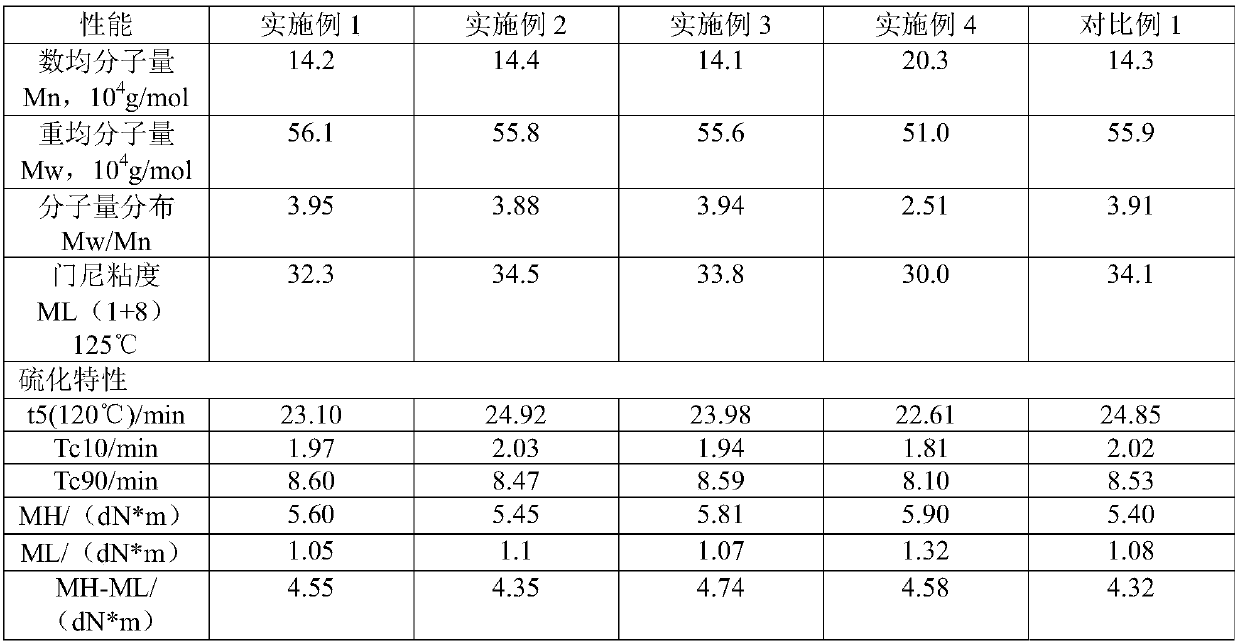

Embodiment 1

[0047] The solvent composition of cleaning butyl rubber polymerization reactor: based on the total amount of solvent, C 6 aliphatic alkanes and C 6 The total content of cycloaliphatic alkanes is 99.97wt%, wherein the content of n-hexane is 88.37wt%, C 5 aliphatic alkanes, C 7 aliphatic alkanes, C 5 cycloaliphatic alkanes and C 7 The total content of alicyclic alkanes is 150ppm, the bromine value of the solvent is 15mg / 100g, and the distillation range of the solvent is 68-70.5°C.

[0048] (1) Send 13000kg of the above-mentioned solvent into the storage tank, and pump it at a rate of 75m 3 The flow rate per hour is sent to the polymerization reactor of butyl rubber, and at the same time, the stirring of the polymerization reactor is started to obtain a solution containing butyl rubber, and a small amount of low-pressure liquid ethylene is passed into the heat exchange tube of the polymerization reactor to control the temperature of the solvent The temperature is 45°C, and t...

Embodiment 2

[0057] The solvent composition of cleaning butyl rubber polymerization reactor: based on the total amount of solvent, C 6 aliphatic alkanes and C 6 The total content of cycloaliphatic alkanes is 99.95wt%, wherein the content of n-hexane is 85.1wt%, C 5 aliphatic alkanes, C 7 aliphatic alkanes, C 5 cycloaliphatic alkanes and C 7 The total content of alicyclic alkanes is 200ppm, the bromine value of the solvent is 30mg / 100g, and the distillation range of the solvent is 68-70.5°C.

[0058] (1) Send 13000kg of the above-mentioned solvent into the storage tank, and pump it at a rate of 60m 3 The flow rate per hour is sent to the polymerization reactor of butyl rubber, and at the same time, the stirring of the polymerization reactor is started to obtain a solution containing butyl rubber, and a small amount of low-pressure liquid ethylene is passed into the heat exchange tube of the polymerization reactor to control the temperature of the solvent The temperature is 35°C, and th...

Embodiment 3

[0065] The solvent composition of cleaning butyl rubber polymerization reactor: based on the total amount of solvent, C 6 aliphatic alkanes and C 6 The total content of cycloaliphatic alkanes is 99.93wt%, wherein the content of n-hexane is 87.0wt%; C 5 aliphatic alkanes, C 7 aliphatic alkanes, C 5 cycloaliphatic alkanes and C 7 The total content of alicyclic alkanes is 50ppm, the bromine value of the solvent is 20mg / 100g, and the distillation range of the solvent is 68-70.5°C.

[0066] (1) Send 13000kg of the above-mentioned solvent into the storage tank, and pump it at a rate of 90m 3The flow rate per hour is sent to the polymerization reactor of butyl rubber, and at the same time, the stirring of the polymerization reactor is turned on to obtain a solution containing butyl rubber, and the solution containing butyl rubber flowing out from the polymerization reactor passes through a heat exchanger to control the solution with circulating water The temperature is 50°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com