A Combinatorial Approach to Producing High-Value Products

A combined method and high-value technology, applied in the field of hydrocarbon oil cracking, can solve the problems of small improvement in product quality and high coke yield, and achieve the effects of increasing overall economic benefits, increasing yield, and reducing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

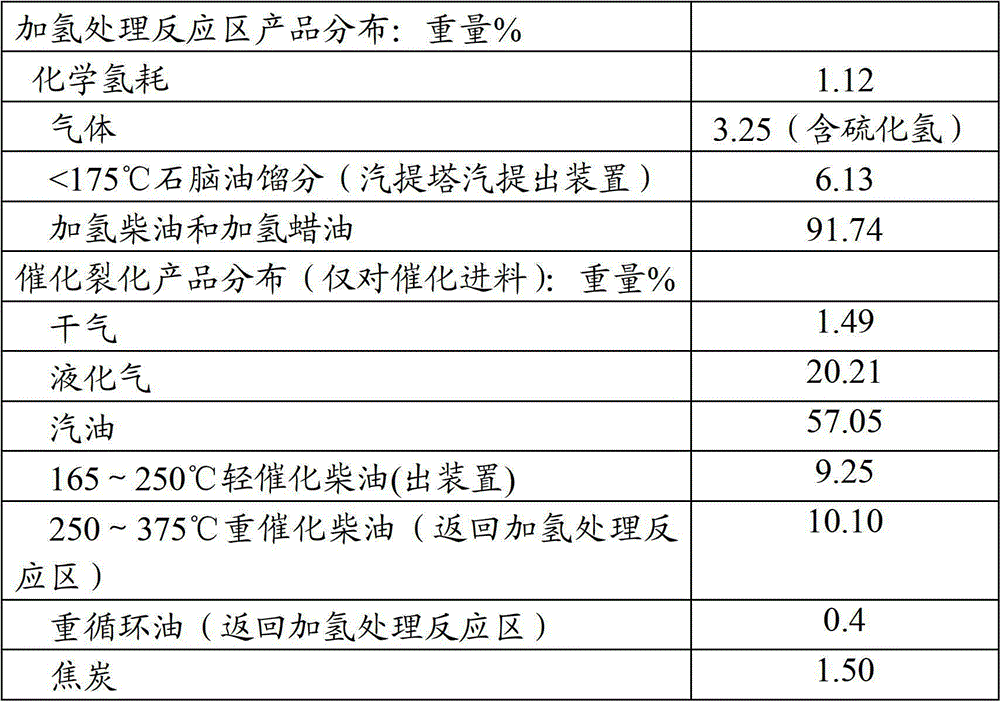

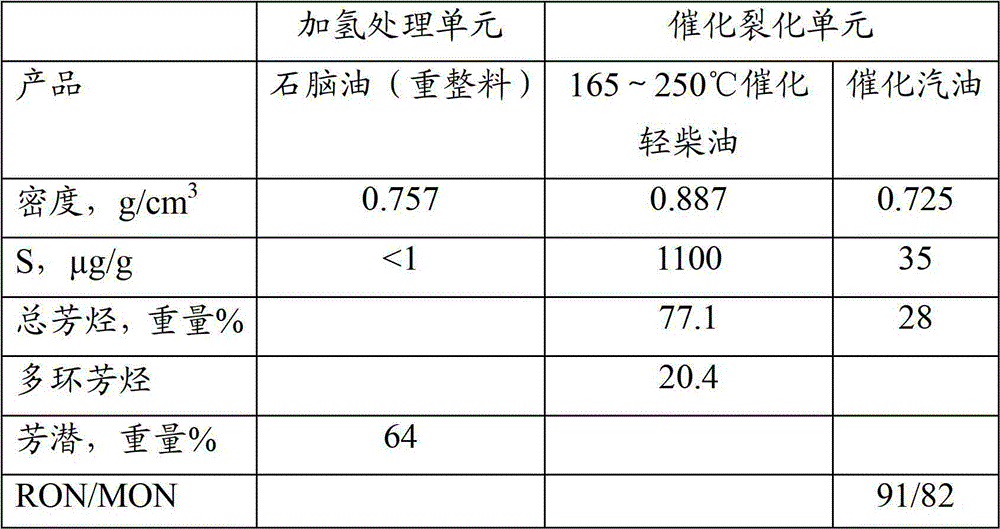

Examples

Embodiment Construction

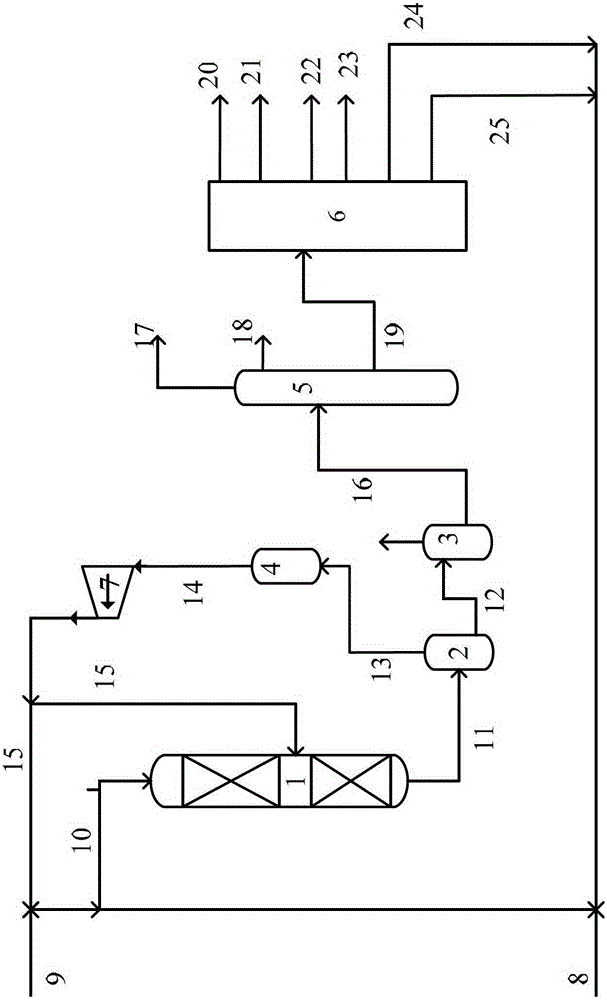

[0039] The method provided by the present invention will be further described below in conjunction with the drawings. The accompanying drawing is a schematic flow diagram of the combination method provided by the present invention. Many devices are omitted in the figure, such as pumps, heat exchangers, compressors, etc., but this is well known to those of ordinary skill in the art.

[0040] After the inferior wax oil feedstock from line 8 is mixed with fresh hydrogen from line 9 and circulating hydrogen from line 15, the mixed material enters hydrotreating reactor 1 through line 10, and is successively combined with hydroprotective agent, hydrodemetalization and desulfurization. After the catalyst and the wax oil hydrotreating catalyst are in contact, the hydrodesulfurization, hydrodenitrogenation, aromatic hydrogenation saturation, and hydrodemetalization reactions are carried out. The resulting hydrogenated oil enters the vapor-liquid high-pressure separator 2 through the pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com