Cationic rosin size prepared by using Gemini emulsifier and preparation method thereof

A cationic rosin gum and emulsifier technology, which is applied in the field of cationic rosin gum and its preparation, can solve the problems of weak emulsification synergistic effect, lower paper quality, and poor single emulsification effect, achieve superior emulsification performance and stability, and reduce production costs , the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

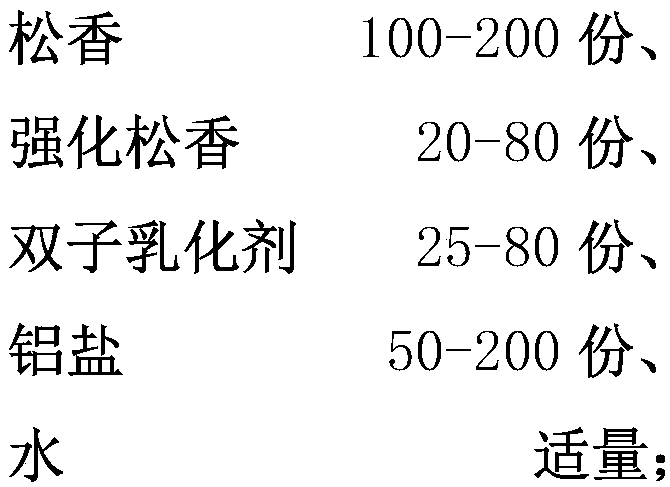

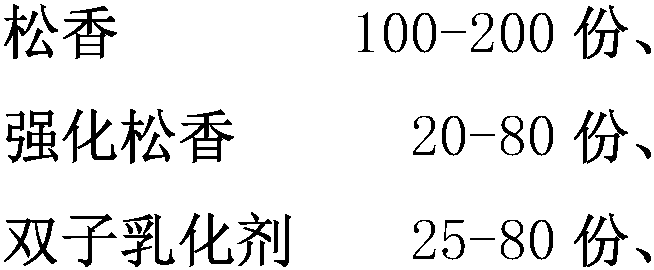

[0040] Put 200g of rosin and 100g of maleic rosin mixture into the bottom of the reaction kettle, heat to about 150°C to melt; first keep the stirring speed at about 200 rpm, slowly add 80g of gemini emulsifier specially for rosin gum, and the dropping time is 30min. Increase the stirring speed to 1500 rpm during the dropwise addition process, and continue to stir for 5 minutes after the emulsifier is added; keep 200g of deionized water at about 60°C, and slowly drop it into the reactor for 25 minutes. During the dropping process, reduce the stirring speed to 200 rpm; cool the material in the reactor to below 30°C, add 50g of aluminum sulfate, and then add 350g of cold deionized water to adjust the solid content to 35% before discharging.

Embodiment 2

[0042] Put 200g of rosin and 100g of fuma rosin mixture into the bottom of the reaction kettle, heat it to about 150°C and melt it; first keep the stirring speed at about 200 rpm, slowly add 80g of gemini emulsifier specially for rosin gum, and the dropping time is 30min. Increase the stirring speed to 1500 rpm during the dropwise addition process, and continue to stir for 5 minutes after the emulsifier is added; keep 200g of deionized water at about 60°C, and slowly drop it into the reactor for 25 minutes. During the dropping process, reduce the stirring speed to 200 rpm; cool the material in the reactor to below 30°C, add 60g of aluminum chloride, add 350g of cold deionized water to adjust the solid content to 35%, and then discharge the material .

Embodiment 3

[0044] Put 200g of rosin and 100g of fuma rosin mixture into the bottom of the reaction kettle, heat it to about 150°C and melt it; first keep the stirring speed at about 200 rpm, slowly add 80g of gemini emulsifier specially for rosin gum, and the dropping time is 30min. Increase the stirring speed to 1500 rpm during the dropwise addition process, and continue to stir for 5 minutes after the emulsifier is added; keep 200g of deionized water at about 60°C, and slowly drop it into the reactor for 25 minutes. During the dropping process, reduce the stirring speed to 200 rpm; cool the material in the reactor to below 30°C, add 50g of aluminum sulfate, and then add 350g of cold deionized water to adjust the solid content to 35%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com