Tobacco active component and extraction method and application thereof

A technology of active components and extraction methods, which is applied in the field of tobacco product processing and extraction, and can solve the problems of low content of tobacco active components, toxicity, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

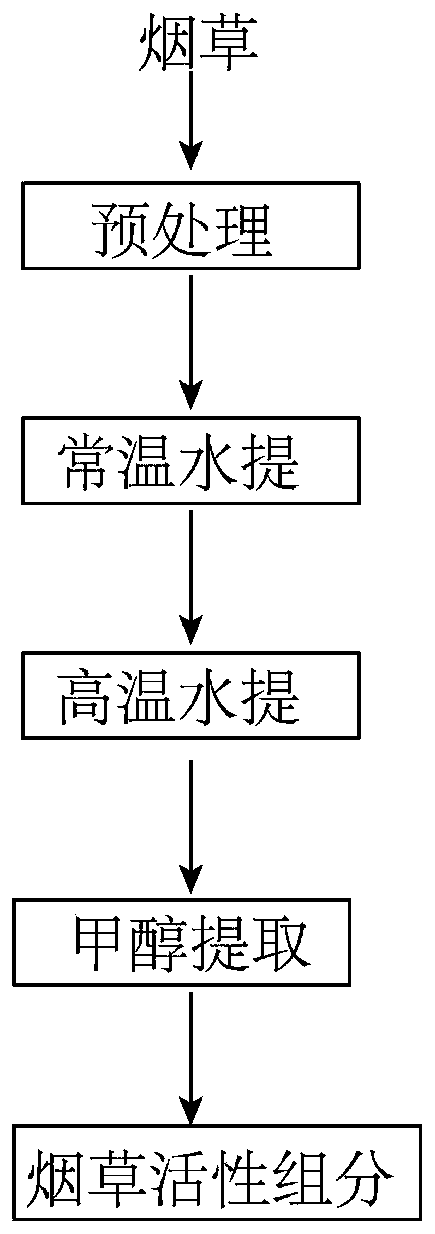

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 of the present invention provides a kind of extraction method of tobacco active component, comprises the following steps:

[0041] (1) Pretreatment.

[0042] Weigh 30Kg of tobacco raw material, place it in an oven for drying, the drying temperature is 50°C, the drying time is 4h, and take out after drying until the moisture content of the tobacco is less than 5%; take the dried tobacco raw material, and use a 50-mesh screen After pulverizing by the pulverizer, put it into a pulverizer with a 200-mesh sieve for superfine pulverization to obtain superfine tobacco powder.

[0043] (2) extraction with normal temperature water.

[0044] Weigh 30Kg of tobacco superfine powder into a 200L extraction tank, add 100Kg of purified water, stir and extract at room temperature for 0.5h; of sediment.

[0045] (3) High temperature water extraction.

[0046] Weigh 25Kg of the precipitate in step (2) and add it to a 100L concentrated extraction tank; add 60Kg of purified...

Embodiment 2

[0050] Embodiment 2 of the present invention provides a kind of extraction method of tobacco active component, comprises the following steps:

[0051] (1) Pretreatment.

[0052] Weigh 40Kg of tobacco raw material, place it in an oven for drying, the drying temperature is 55°C, the drying time is 6h, and take out after drying until the moisture content of the tobacco is less than 5%; take the dried tobacco raw material, and use a 60-mesh screen After being pulverized by a pulverizer, put it into a pulverizer with a 300-mesh screen for superfine pulverization to obtain superfine tobacco powder.

[0053] (2) extraction with normal temperature water.

[0054] Weigh 40Kg of tobacco superfine powder into a 200L extraction tank, add 120Kg of purified water, stir and extract at room temperature for 1.5h; transfer to a centrifuge bottle after stirring and extraction, and centrifuge at 10°C for 1h at a speed of 5000rpm / min; collect centrifuged Precipitate.

[0055] (3) High temperatu...

Embodiment 3

[0060] Embodiment 3 of the present invention provides a kind of extraction method of tobacco active component, comprises the following steps:

[0061] (1) Pretreatment.

[0062] Weigh 50Kg of tobacco raw material, place it in an oven for drying, the drying temperature is 60°C, the drying time is 8h, and take out after drying until the moisture content of the tobacco is less than 5%. Take the dried tobacco raw material and use an 80-mesh screen After pulverizing by the pulverizer, put it into a pulverizer with a 400-mesh sieve for superfine pulverization treatment to obtain superfine tobacco powder.

[0063] (2) extraction with normal temperature water.

[0064] Weigh 50Kg of tobacco superfine powder into a 200L extraction tank, add 120Kg of purified water, stir and extract at room temperature for 0.5h; of sediment.

[0065] (3) High temperature water extraction.

[0066] Weigh 45Kg of the precipitate in step (2) and add it to a 100L concentrated extraction tank; add 60Kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com