Continuous particle surface modification reactor adopting drying method

A surface modification and reactor technology, which is applied in the direction of granulation of raw materials, chemical/physical/physicochemical fixed reactors, material granulation and coating, etc., can solve the problem of continuous modification and particle modification. Poor performance, complex equipment structure and other problems, to achieve easy control, improve the effect of modification, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

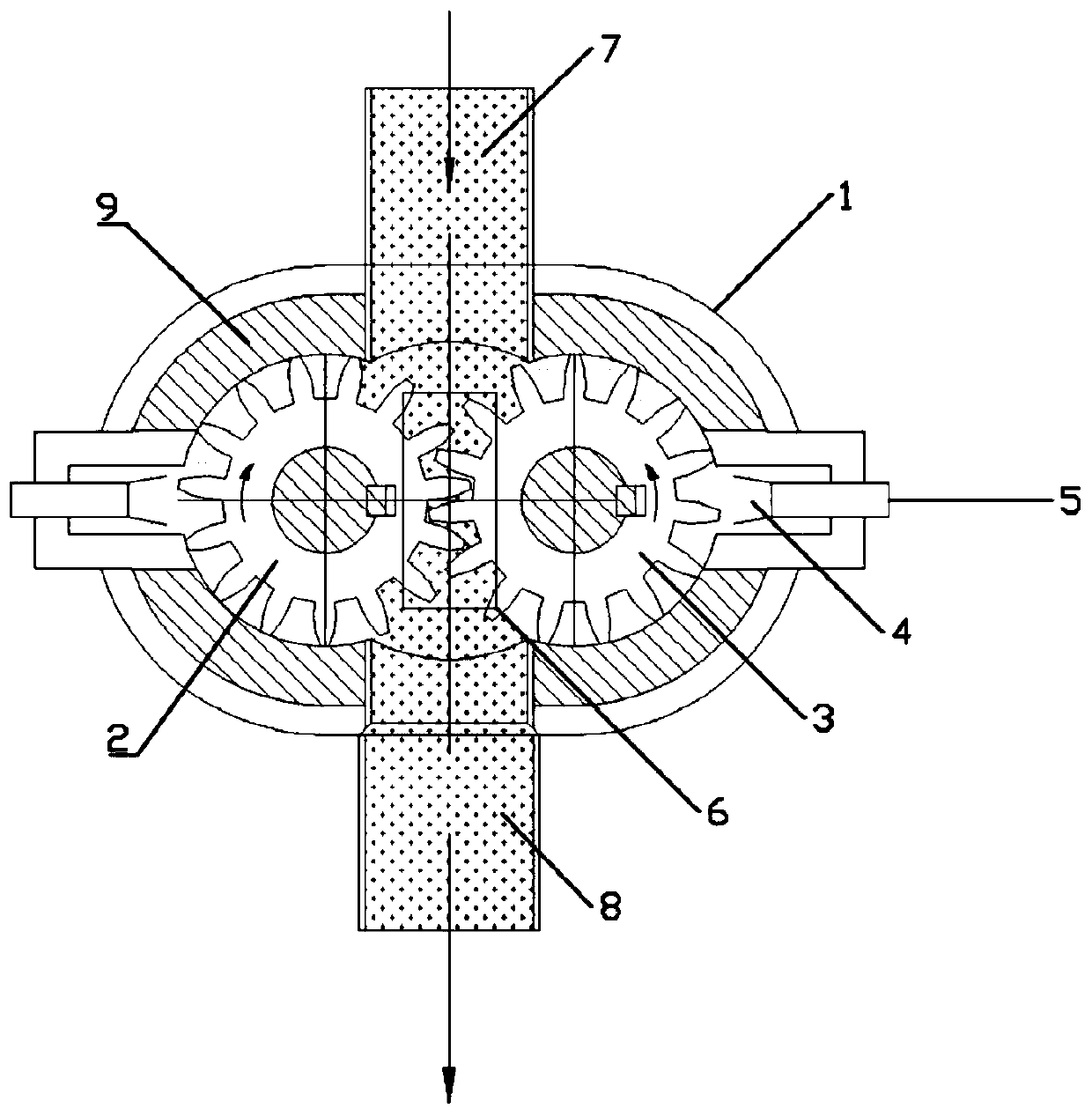

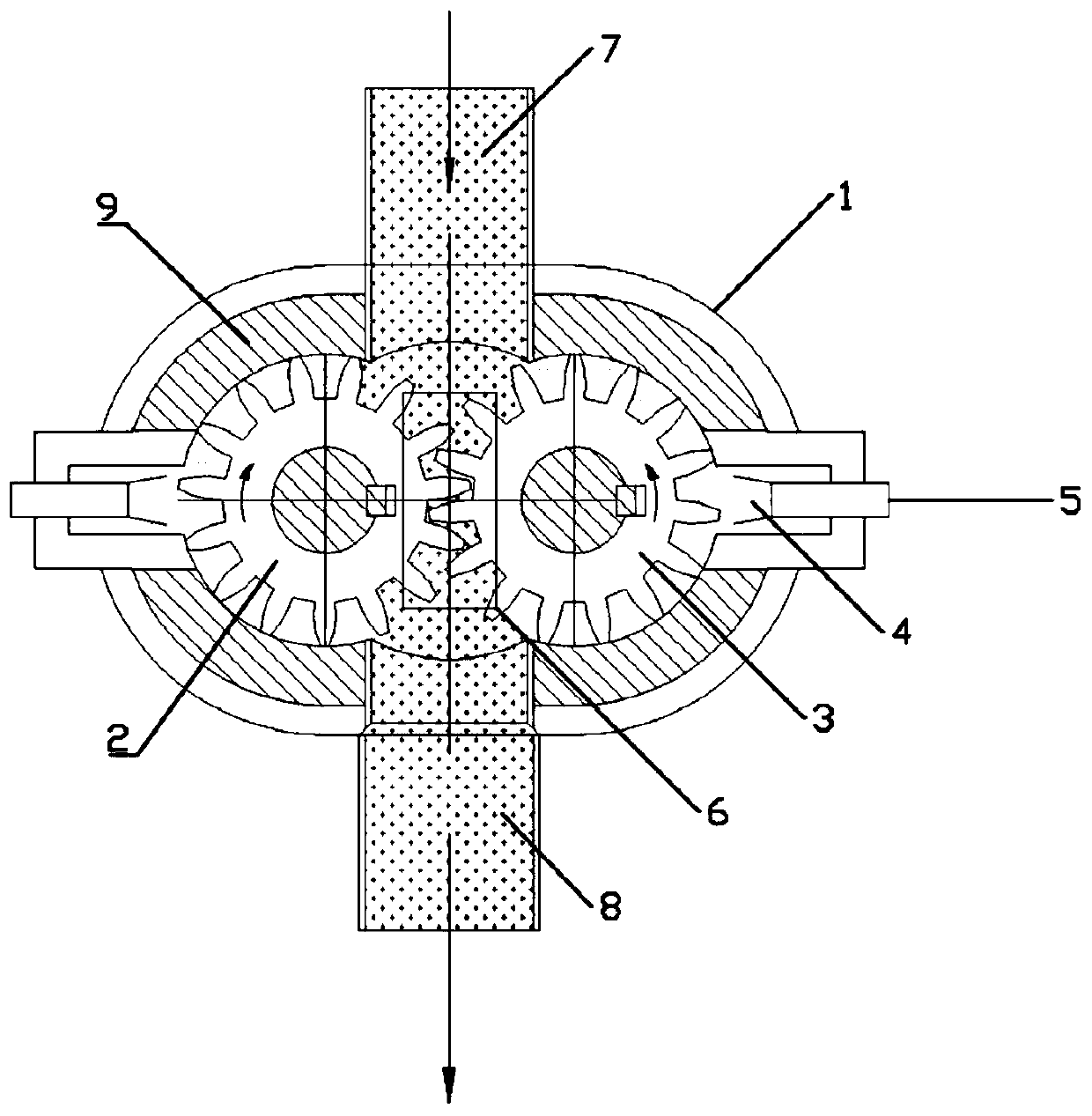

[0031] The structure and working principle of the present invention will be further described in detail below in conjunction with the drawings.

[0032] As shown in the figure, the present invention includes a cylinder body 1, which is made of high-strength stainless steel, and plays a structural support role for the entire reactor. There is an arc-shaped heating device 9 in the cylinder body, and the heating temperature is at room temperature - 300 ° C. The heating is for To promote the modification, the inner wall of the heating device has an anti-adhesive layer to prevent the material or modifier from sticking to the inner wall. There is an atomization chamber 4 on both sides of the reactor, the volume of the atomization chamber is 200-300ml, the atomized surface modifier in the atomizer 5 is in the form of mist, and the atomized surface modifier is rotated Gear 2 and gear 3 are brought to feed port 7 to realize the combination of surface modifier and material, the speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com