Modified asphalt coating material and preparation method thereof and mineral pellet-modified asphalt waterproof coil material and preparation method of mineral pellet-modified asphalt waterproof coil material

A technology of modified asphalt and mineral pellets, which is applied in asphalt coatings, chemical instruments and methods, and natural mineral layered products, etc. It can solve problems such as shrinkage, tearing, and narrowing and deformation of the tire base, and achieve improved stability. Sex and tear strength, meet the needs of production and use, and reduce the effect of production viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

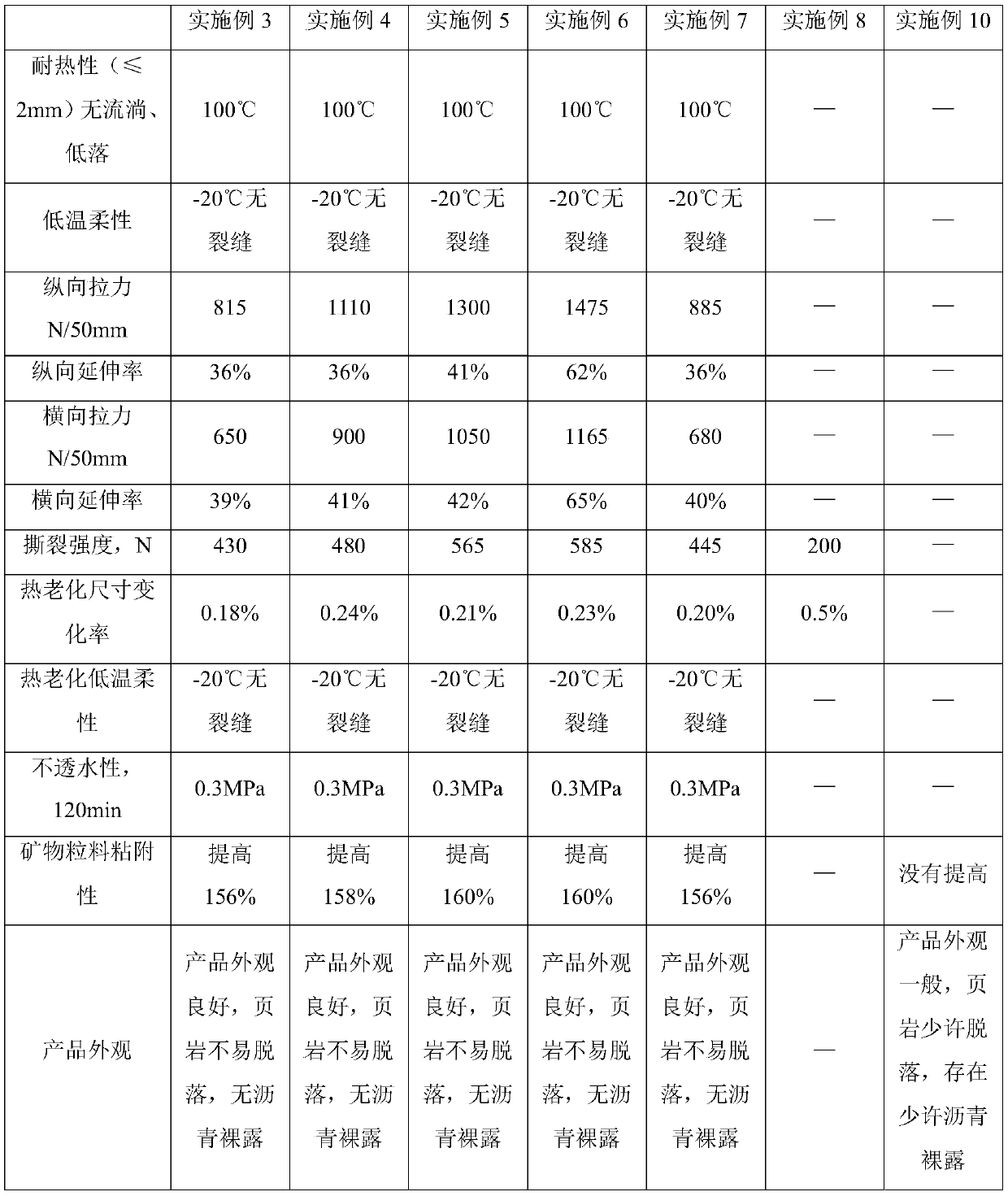

Examples

preparation example Construction

[0032] The second aspect of the present invention provides a method for preparing the above-mentioned modified asphalt coating material. The preparation method includes: mixing the petroleum asphalt and hot-mix asphalt uniformly; then grinding with the SBS, polyethylene wax and tackifying resin Mixing; finally mixing with the filler to obtain the modified asphalt coating material.

[0033] According to the present invention, preferably, the grinding and mixing temperature is 180-190°C, and the grinding and mixing time is 2-4 h.

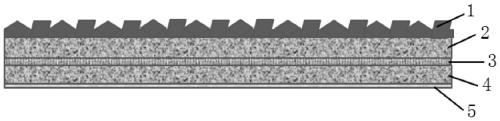

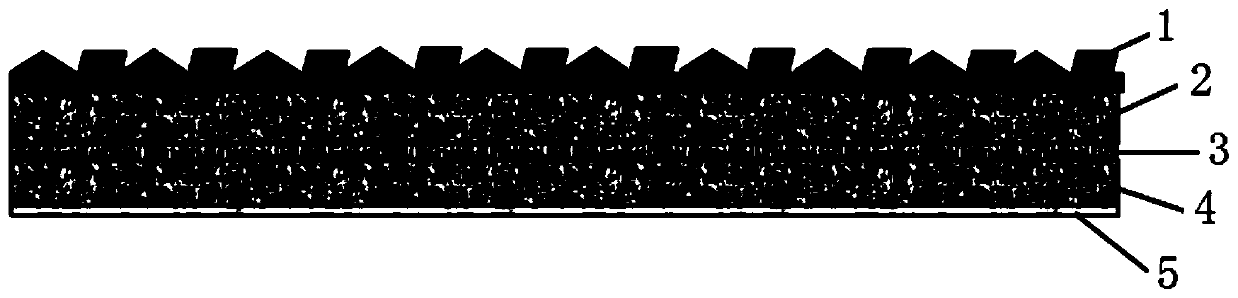

[0034] The third aspect of the present invention provides a mineral pellet modified asphalt waterproofing membrane, which in turn includes: a first insulating material layer, a first modified asphalt coating layer, a tire base layer, and a second modified asphalt The coating material layer and the second insulation material layer; wherein the first insulation material layer is a mineral granular material layer; the coating used for the first modified aspha...

Embodiment 1

[0056] This embodiment provides a modified asphalt coating material. The specific preparation method is: mix 50 parts of No. 90 petroleum asphalt and 10 parts of hot-mixed asphalt uniformly; then mix with 13 parts of SBS, 4 parts of polyethylene wax and 2 parts of C5 petroleum Add the resin to the colloid mill together, turn on the stirring and colloid mill grinding, the grinding time is 3h, control the temperature of mixing and grinding at 185℃, so that the modifier (SBS, polyethylene wax and C5 petroleum resin) is fully dissolved, and there is nothing in the modified asphalt Granules; Finally, 21 parts of 400 mesh light calcium carbonate are added to the batching tank, and stirring is continued for 1 h to obtain the modified asphalt coating material.

Embodiment 2

[0058] This embodiment provides a modified asphalt coating material. The specific preparation method is: mix 45 parts of No. 90 petroleum asphalt and 7 parts of hot-mixed asphalt uniformly; then mix with 14 parts of SBS, 3 parts of polyethylene wax and 4 parts of C5 petroleum Add the resin to the colloid mill together, turn on the stirring and colloid mill grinding, the grinding time is 3h, control the temperature of mixing and grinding at 185℃, so that the modifier (SBS, polyethylene wax and C5 petroleum resin) is fully dissolved, and there is nothing in the modified asphalt Granules; Finally, 30 parts of 400 mesh light calcium carbonate are added to the batching tank, and stirring is continued for 1 hour to obtain the modified asphalt coating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com