Fucus oligosaccharide and preparation method and application thereof

A technology of fucoidan oligosaccharides and fucoidan, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low absorption rate and bioavailability, and achieve good moisturizing effect and high fat content. Acidase inhibitory activity, high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

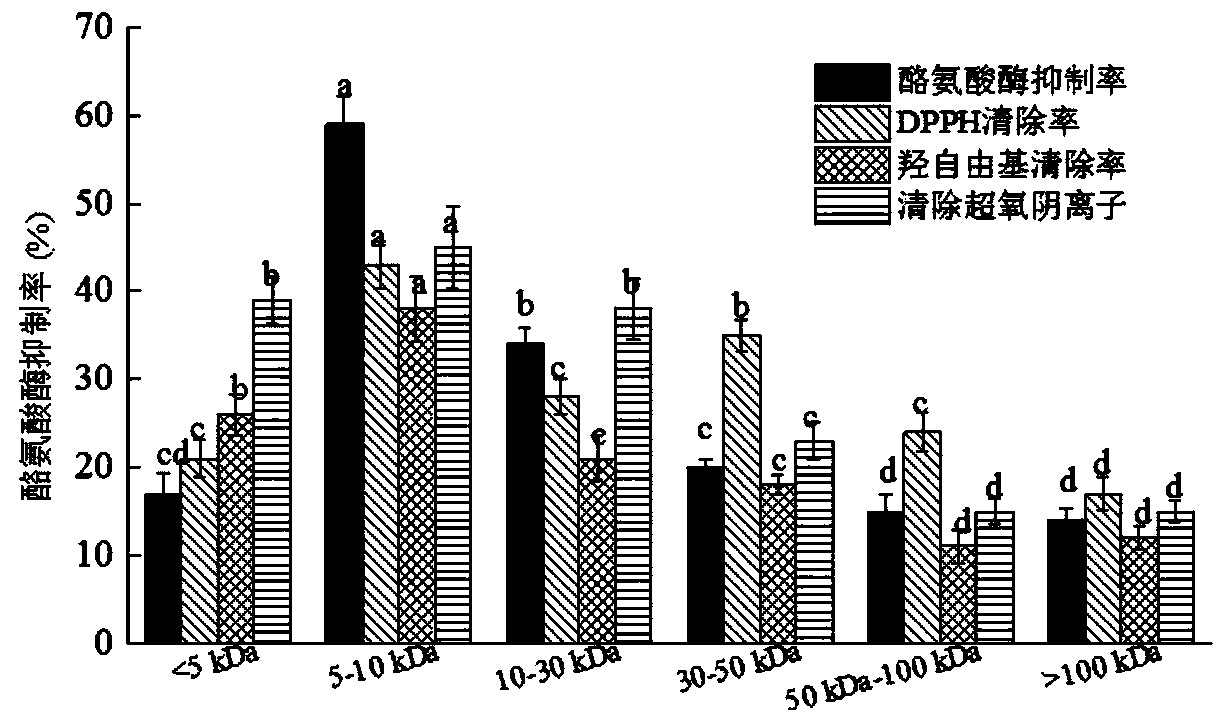

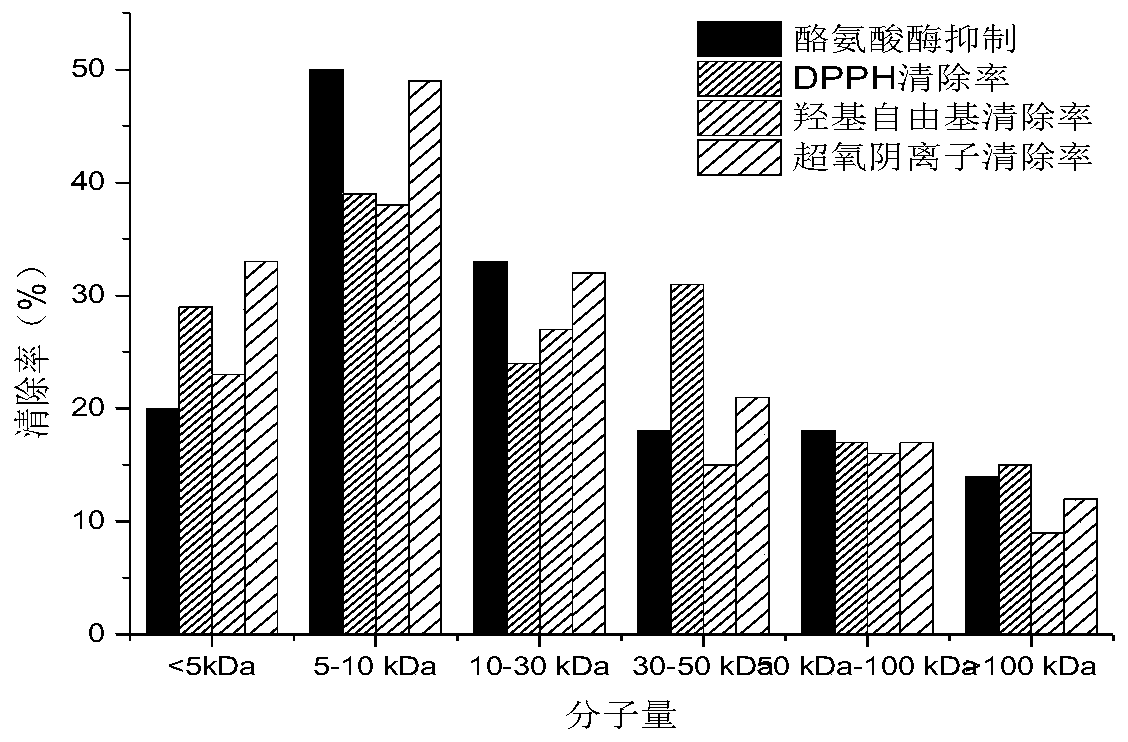

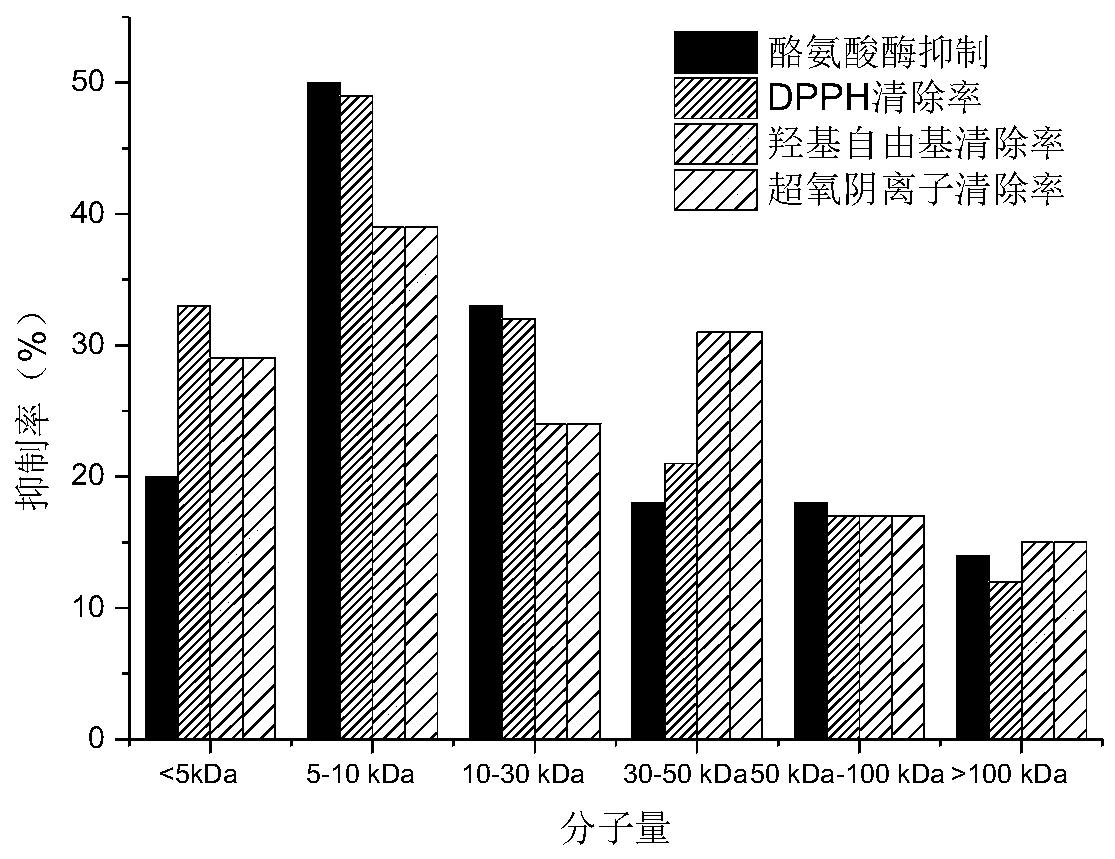

[0061] Example 1 Preparation of fucoidal oligosaccharides

[0062] Fucoidan was treated with 0.01-0.5M H 2 SO 4 Prepare a fucoidan solution with a concentration of 0.3% to 1%, put the fucoidan aqueous solution in a water bath at 60 to 80°C, degrade for 3 to 12 hours, and start to degrade at a shaker speed of 50 to 180r / min. After the degradation is complete, Ba(OH) is added to the aqueous solution 2 powder, make the pH of the fucoidan solution to neutral to terminate the reaction. Centrifuge the final solution (5000r / min, 10min), take the supernatant, and use the ultrafiltration membrane system to divide the fucoidan degradation solution into less than 5kDa, 5-10kDa, 10-30kDa, 30-50kDa, 50-100kDa, and greater than The molecular weight segment of 100kDa was separately freeze-dried to obtain fucoidan oligosaccharide powder.

[0063] Set up three experimental groups A1, A2, and A3, and prepare them according to the following conditions:

[0064]

[0065] The degradation p...

Embodiment 2

[0067] Example 2 Preparation of fucoidal oligosaccharides

[0068] The fucoidan is formulated with 0.01-0.5M HCl to form a fucoidan solution with a concentration of 0.3%-1%. Put the fucoidan aqueous solution in a water bath at 90-100°C, degrade it for 3-12 hours, and start the degradation with the rotating speed of the shaker at 50-180r / min. After the degradation is completed, NaOH powder is added to the aqueous solution to make the pH of the fucoidan solution to neutral to terminate the reaction. Centrifuge the final solution (5000r / min, 10min), take the supernatant, and use the ultrafiltration membrane system to divide the fucoidan degradation solution into fractions of less than 5kDa, 5~10kDa, 10~30kDa, 30- 50kDa, 50-100kDa, molecular weight segment greater than 100kDa, through freeze-drying to powder state is fucoid oligosaccharide.

[0069] Set up three experimental groups B1, B2, and B3, and prepare them according to the following conditions:

[0070]

[0071] Acco...

Embodiment 3

[0072] Example 3 Preparation of fucoidal oligosaccharides

[0073] Weigh 1-5g fucoidan respectively, add 25-80ml 90% formic acid, stir and mix, heat and react in a water bath at 60-90°C, react for 3-12h, and remove formic acid with 25-80ml absolute ethanol after the reaction. Using a membrane ultrafiltration system with a molecular weight cut-off of 5000Da, 10000Da, 30000Da, 50000Da, and 1000000Da, the fucoidan degradation solution is divided into molecular weight segments less than 5kDa, 5-10kDa, 10-30kDa, 30-50kDa, 50-100kDa, and greater than 100kDa. Fucoidal oligosaccharides are obtained by freeze-drying to a powder state.

[0074] Set up three experimental groups C1, C2, and C3, and prepare them according to the following conditions:

[0075]

[0076] The degradation products of fucoidan oligosaccharides prepared by experimental groups B1, B2, and B3 were analyzed by gravimetric analysis and high-performance liquid chromatography. For specific methods, refer to Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com