Preparation method of gradient-color macromolecule dye

A technology of macromolecular dyes and gradient colors, which is applied in the field of preparation of gradient macromolecular dyes, can solve the problems of high processing difficulty, solvent intolerance, high dye cost, etc., and achieves simple and easy operation, time-saving and cost-saving preparation methods. , the effect of zero waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

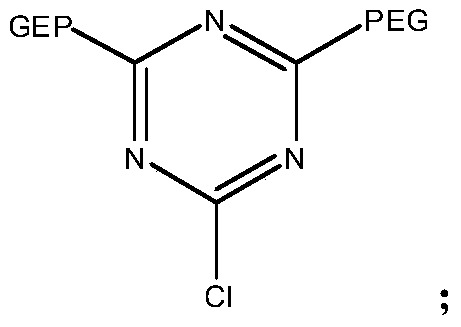

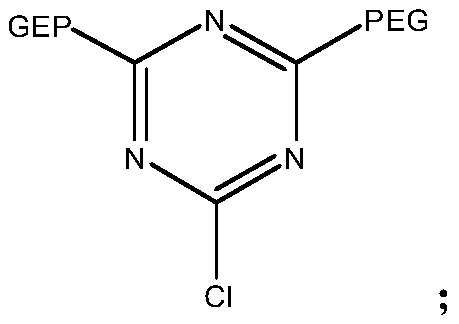

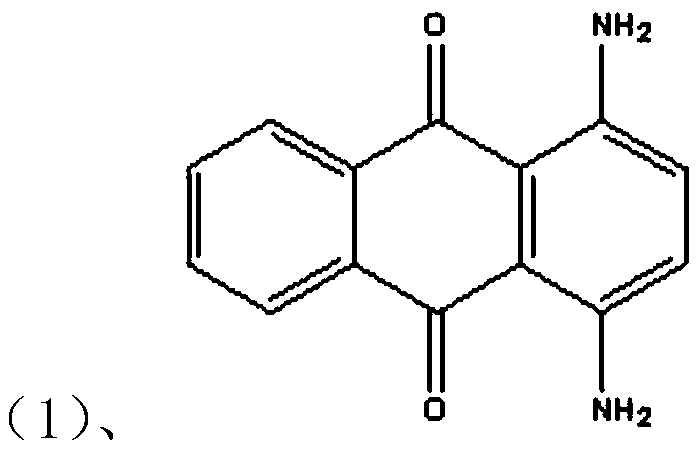

[0029] First add cyanuric chloride to water and stir evenly, water bath at 30-40°C, then add PEG, wherein the molar ratio of cyanuric chloride to PEG is 0.5:1, keep warm in a water bath at 30-40°C, add prepared 40% sodium acetate The solution is kept at pH=3.0-3.5 and reacted for 3-4 hours, and the reaction is completed to obtain a macromolecular precursor. Then add the yellow small molecule chromogenic compound formula (1), wherein the mol ratio of the small molecular chromogenic compound to cyanuric chloride is 0.5:1, then add the colorless wood lacquer wherein, wherein the wood lacquer and the small molecular chromogenic compound The weight ratio is 5-6:1, stir for 30 minutes until evenly dispersed. Evenly spread the evenly dispersed mixture on the prepared wooden board with a thickness of 20-30μm, put it in an oven at 80-90°C and bake for 1-2 hours, take it out and cool it, and the reaction is completed to obtain a blue paint.

Embodiment 2

[0031] First add cyanuric chloride to water and stir evenly, water bath at 30-40°C, then add PEG, wherein the molar ratio of cyanuric chloride to PEG is 0.5:1, keep warm in a water bath at 30-40°C, add prepared 40% sodium acetate The solution is kept at pH=3.0-3.5 and reacted for 3-4 hours, and the reaction is completed to obtain a macromolecular precursor. Then add the blue three-color small-molecule chromogenic compound formula (2), wherein the mol ratio of the small-molecule chromogenic compound to cyanuric chloride is 0.95:1, then add colorless wood lacquer wherein, wherein wood lacquer and small-molecule chromogenic compound The weight ratio of the color compound is 5-6:1, stir for 30 minutes until uniformly dispersed. Spread the evenly dispersed mixture evenly on the prepared wooden board with a thickness of 20-30μm, put it in an oven at 80-90°C and bake for 1-2 hours, take it out to cool, and the reaction is completed to obtain a purple-red paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com