Green and environmentally friendly bamboo and wood fiber integrated board and manufacturing method thereof

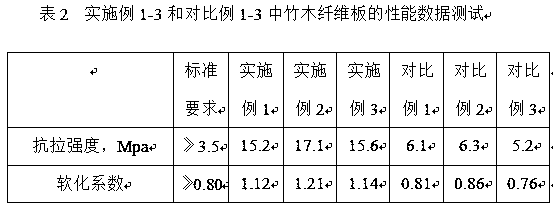

A bamboo-wood fiber, green and environmentally friendly technology, applied in the field of indoor integrated boards, can solve the problems of poor tensile strength and water resistance of bamboo-wood fiberboards, water resistance that cannot meet national standards, and limit the application of bamboo-wood fiberboards. Environmentally friendly performance, improved water resistance, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-2

[0024] A kind of green environmental protection bamboo wood fiber integrated board, the manufacturing method is as follows:

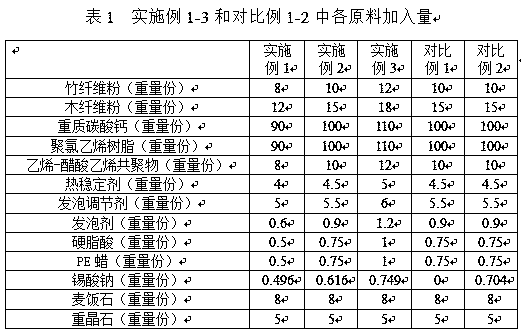

[0025] A. Compounding practice: According to the formula in Table 1, bamboo fiber powder, wood fiber powder, heavy calcium carbonate, polyvinyl chloride resin, ethylene-vinyl acetate copolymer, heat stabilizer, K100 foaming regulator, foaming agent, PE wax, stearic acid, medical stone, barite and tin-containing inorganic compounds were mixed and stirred evenly and pre-plasticized to obtain a mixed material;

[0026] B. Extrusion molding: Add the pre-plasticized blended material in step A to the hopper of the extruder, and control the processing temperature to 150-170°C for extrusion molding;

[0027] C. Shaping and cooling: the material formed in step B passes through the sizing sleeve and enters the vacuum cooling box for shaping and cooling to room temperature;

[0028] D. Sawing and calendering film: cut to get semi-finished products, and then proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com