A low-temperature activator and low-temperature fracturing fluid system

A technology of fracturing fluid and activator, which is applied in the direction of chemical instruments and methods, drilling compositions, etc. It can solve the problems of inability to break the gel or the long time of breaking the gel, high residue content, incomplete gel breaking, etc., and achieve easy Large-scale production, simple preparation process and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

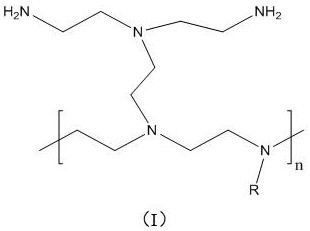

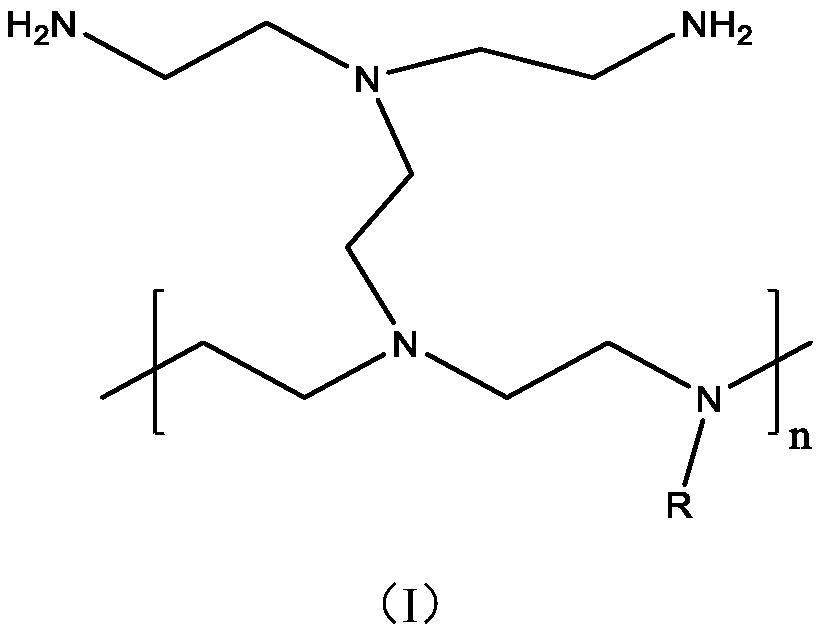

Method used

Image

Examples

preparation example Construction

[0049] The embodiment of the present application further provides a method for preparing the above-mentioned low-temperature fracturing fluid. The addition amount of each component is determined according to the above-mentioned low-temperature fracturing fluid ratio. The preparation steps include:

[0050]S1. Add the primary hydroxypropyl guar gum into the water under stirring condition, and keep stirring for 10 minutes to obtain the first mixed solution.

[0051] S2. After stirring the first mixed solution, adding the clay stabilizer, drainage aid and low-temperature activator into the first mixed solution in sequence to obtain a second mixed solution.

[0052] S3. After stirring the second mixed solution, adding the gel breaker into the second mixed solution to obtain a third mixed solution.

[0053] S4. During the process of fully stirring the third mixed solution, adding the organoboron crosslinking agent into the third mixed solution to obtain a fourth mixed solution. St...

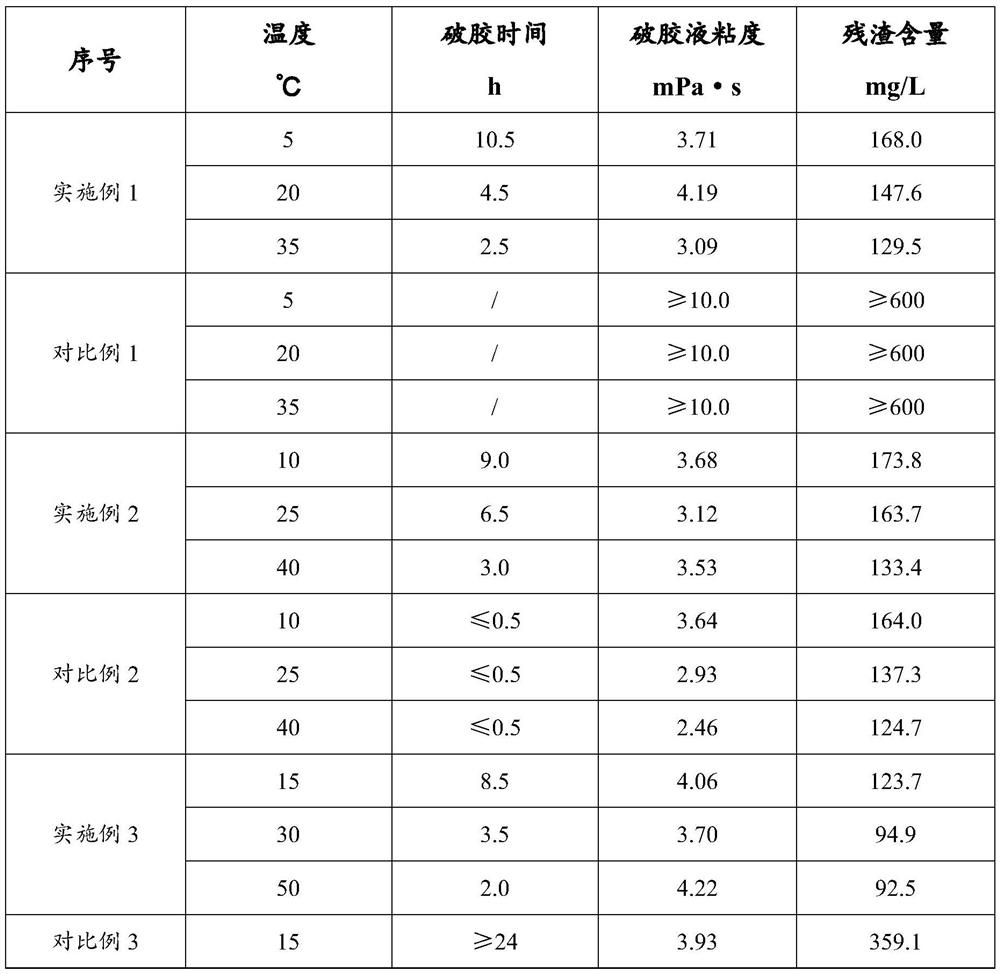

Embodiment 1

[0062] This embodiment provides a low-temperature activator and low-temperature fracturing fluid.

[0063] A low-temperature activator. In parts by weight, 8 parts of polyamine compounds, 25 parts of small-molecular organic amines and 35 parts of water are compounded to obtain a low-temperature activator, wherein 25 parts of small-molecular organic amines are composed of 8 parts of ethylenediamine , 10 parts of triethanolamine and 7 parts of urea.

[0064] Prepare the low-temperature fracturing fluid according to the preparation method of the aforementioned low-temperature fracturing fluid, wherein the proportioning and composition of the low-temperature fracturing fluid are: in parts by weight, 1.0 parts of low-temperature activator; hydroxypropyl guar gum (first grade) 0.25 parts; 0.25 parts of organic boron crosslinking agent; 1.2 parts of clay stabilizer; 1.2 parts of drainage aid; 0.08 parts of gel breaker; 100 parts of clear water.

[0065] The prepared low-temperature ...

Embodiment 2

[0067] This embodiment provides a low-temperature activator and low-temperature fracturing fluid.

[0068] A low-temperature activator, in parts by weight, is obtained by compounding 12 parts of polyamine compounds, 37 parts of small-molecule organic amines and 44 parts of water, wherein 37 parts of small-molecule organic amines are composed of 13 parts of ethylenediamine , 14 parts of triethanolamine and 10 parts of urea.

[0069] Prepare the low-temperature fracturing fluid according to the preparation method of the aforementioned low-temperature fracturing fluid, wherein the proportioning and composition of the low-temperature fracturing fluid are: in parts by weight, 0.5 parts of low-temperature activator; hydroxypropyl guar gum (first grade) 0.15 parts; 0.20 parts of organic boron crosslinking agent; 0.8 parts of clay stabilizer; 0.8 parts of drainage aid; 0.03 parts of gel breaker; 100 parts of clear water.

[0070] The prepared low-temperature fracturing fluid was plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com