Gel valve suitable for high-sulfur-content gas well oil pipe screw thread and preparation method of gel valve

A technology of jelly valve and high sulfur content, which is applied in the field of jelly valve to achieve the effect of high cross-linking density, stable technology and excellent mineralization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

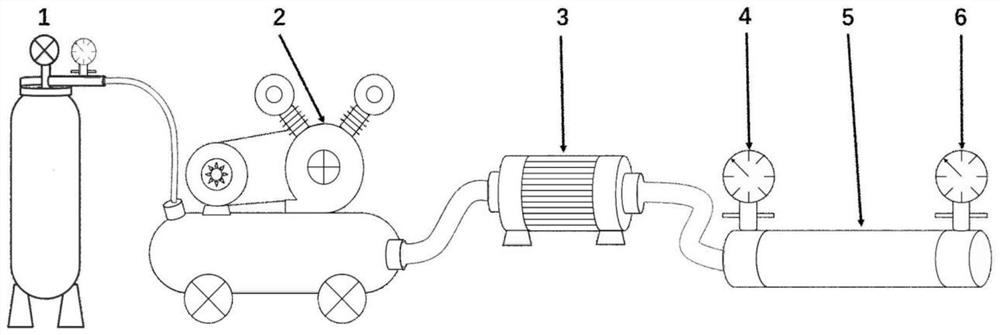

Method used

Image

Examples

Embodiment 1

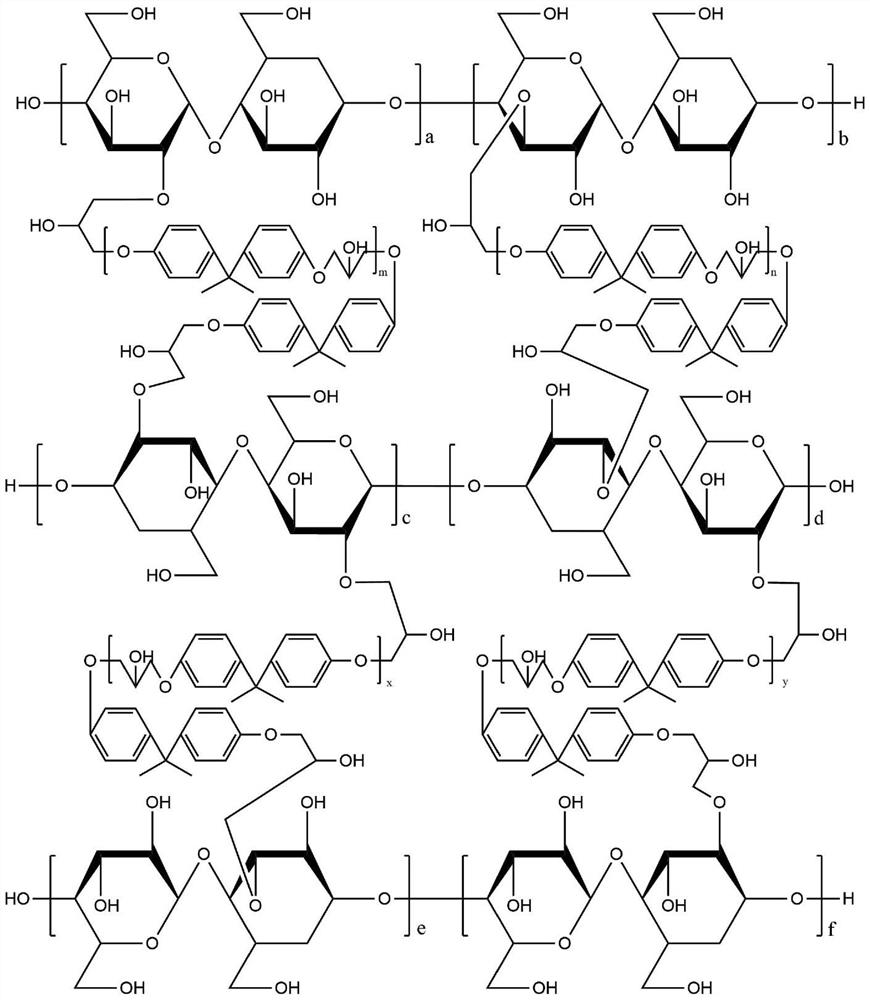

[0031] A jelly valve suitable for high-sulfur gas well oil pipe threads, the jelly valve includes the following raw material components in volume percentage: 50% of base fluid, 30% of cross-linking fluid, and 20% of accelerating fluid.

[0032] The base liquid includes the following raw material components in weight percentage: 10% polyol, 10% preservative, 5% dispersant, 75% water;

[0033] Wherein, the polyhydroxy polymer is potato starch, the preservative is sodium benzoate, and the dispersant is nano silicon dioxide.

[0034] The cross-linking solution includes the following raw material components in weight percentage: 20% of epoxy resin prepolymer, 5% of emulsifier, and 75% of water;

[0035] Wherein, the epoxy resin prepolymer is bisphenol A epoxy resin, and the emulsifier is fatty acid monoglyceride.

[0036] The accelerator liquid includes the following raw material components in weight percentage: 5% of epoxy accelerator and 95% of water; wherein, the epoxy accelera...

Embodiment 2

[0049] A jelly valve suitable for high-sulfur gas well oil pipe threads, the jelly valve includes the following raw material components in volume percentage: 40% of base liquid, 35% of cross-linking liquid, and 20% of accelerating liquid.

[0050] The base liquid includes the following raw material components in weight percentage: 10% polyol, 10% preservative, 5% dispersant, 75% water;

[0051] Wherein, the polyhydroxy polymer is guar gum, the preservative is potassium sorbate, and the dispersant is kaolin.

[0052] The cross-linking solution includes the following raw material components in weight percentage: 20% of epoxy resin prepolymer, 10% of emulsifier, and 70% of water;

[0053] Wherein, the epoxy resin prepolymer is bisphenol F epoxy resin, and the emulsifier is sodium lauryl sulfate.

[0054] The accelerator solution includes the following raw material components in weight percentage: 8% of epoxy accelerator and 92% of water; wherein, the epoxy accelerator is ethylen...

Embodiment 3

[0067] A jelly valve suitable for high-sulfur gas well tubing threads, the jelly valve includes the following raw material components by volume percentage: the jelly valve includes the following raw material components by volume percentage: base liquid 50% , 31.25% of cross-linking liquid, 18.75% of accelerating liquid.

[0068] The base liquid includes the following raw material components in weight percentage: polyol polymer 15%, preservative 10%, dispersant 5%, water 70%;

[0069] Wherein, the polyhydroxy polymer is glutinous rice flour, the preservative is calcium propionate, and the dispersant is talcum powder.

[0070] The cross-linking solution includes the following raw material components in weight percentage: 25% of epoxy resin prepolymer, 10% of emulsifier, and 65% of water;

[0071] Wherein, the epoxy resin prepolymer is glycidyl ether epoxy resin, and the emulsifier is sodium lauryl sulfate.

[0072] The accelerator solution includes the following raw material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com